Method for monitoring fatigue life of airplane structure key part online under spectrum loading on the basis of indirect strain measurement

A technology for key parts and aircraft structures, applied in the field of fatigue life monitoring, can solve the problems of sensor false alarms and large errors, and achieve the effect of ensuring accuracy and reliability and avoiding false alarms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

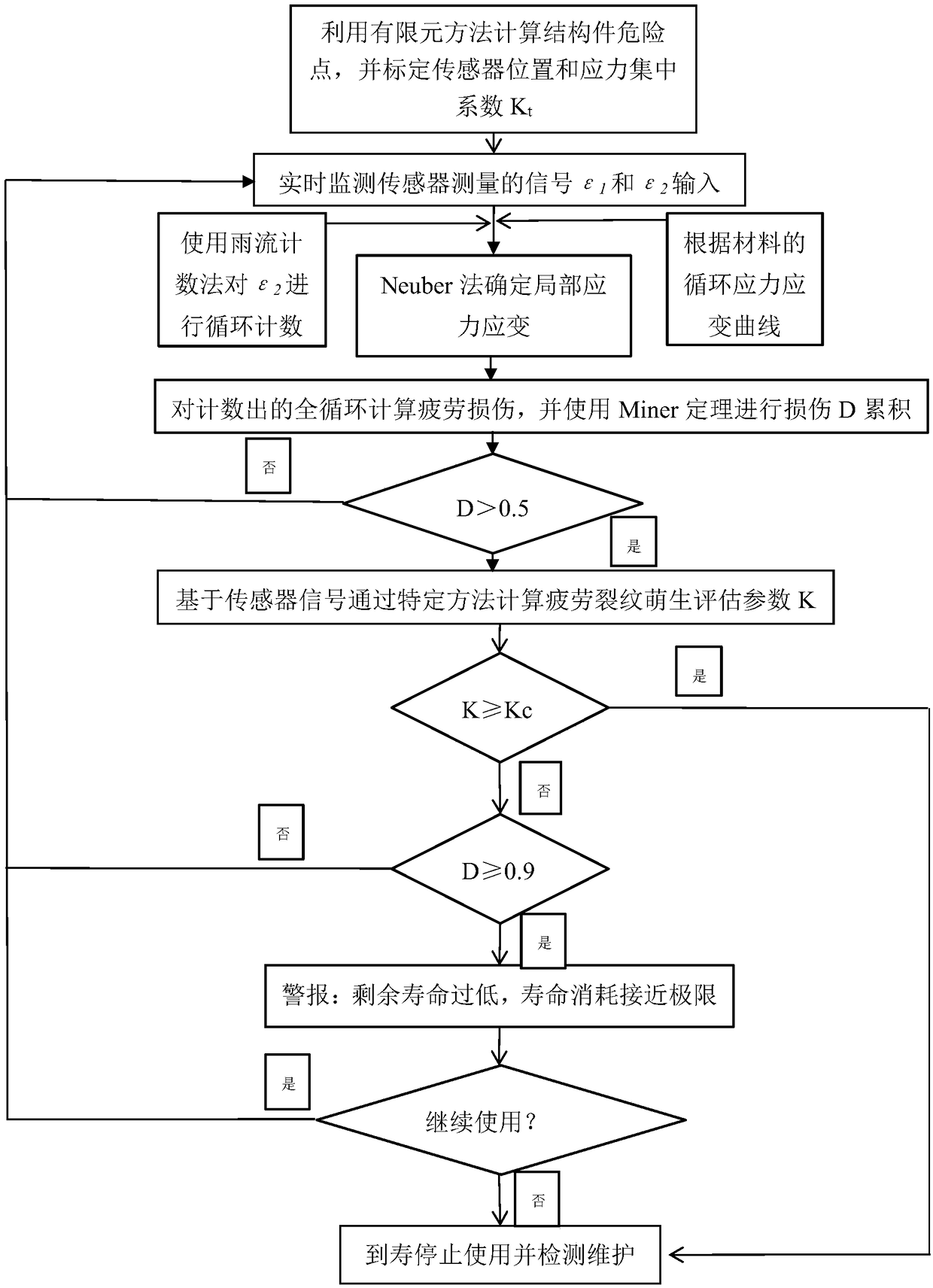

[0031] The specific embodiment of the present invention will be described with reference to the accompanying drawings.

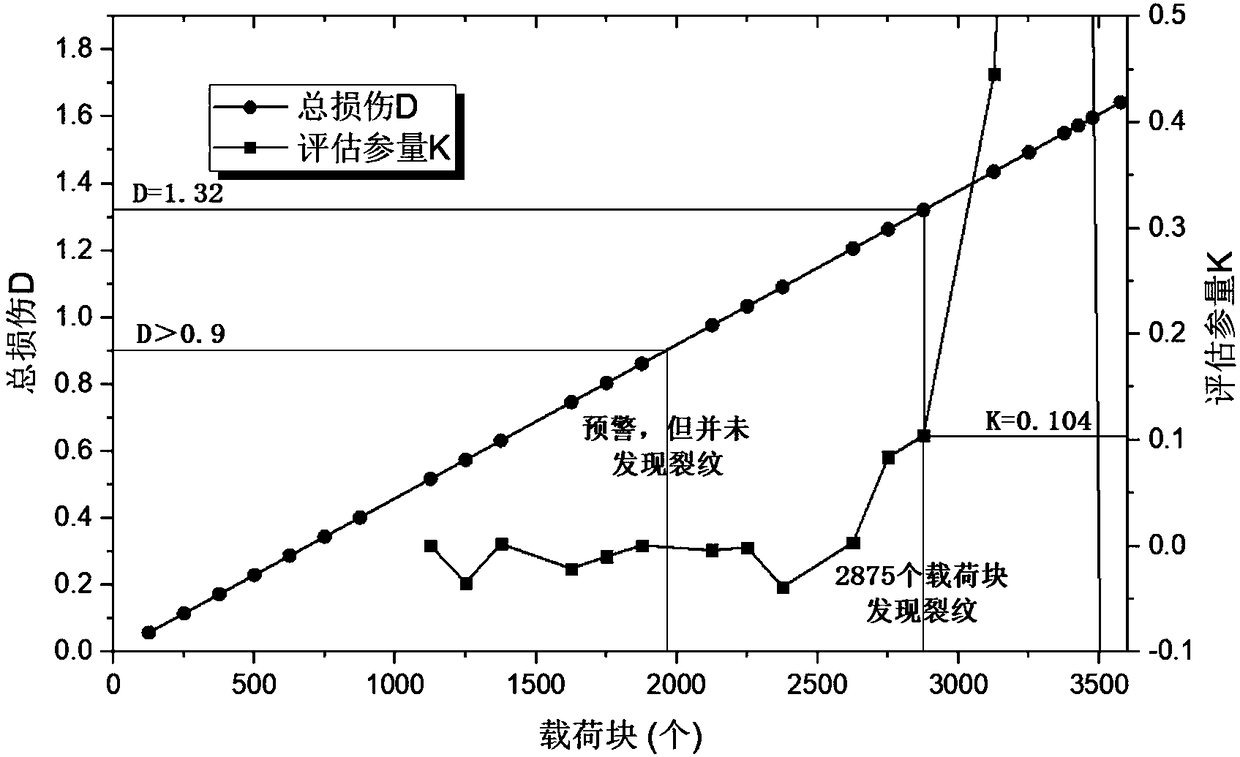

[0032] The present invention has been further illustrated to the present invention by aircraft structure component fatigue test,

[0033] An online monitoring method for fatigue life of key parts of aircraft structure based on indirect measurement of strain under spectral loading, the specific calculation method is as follows:

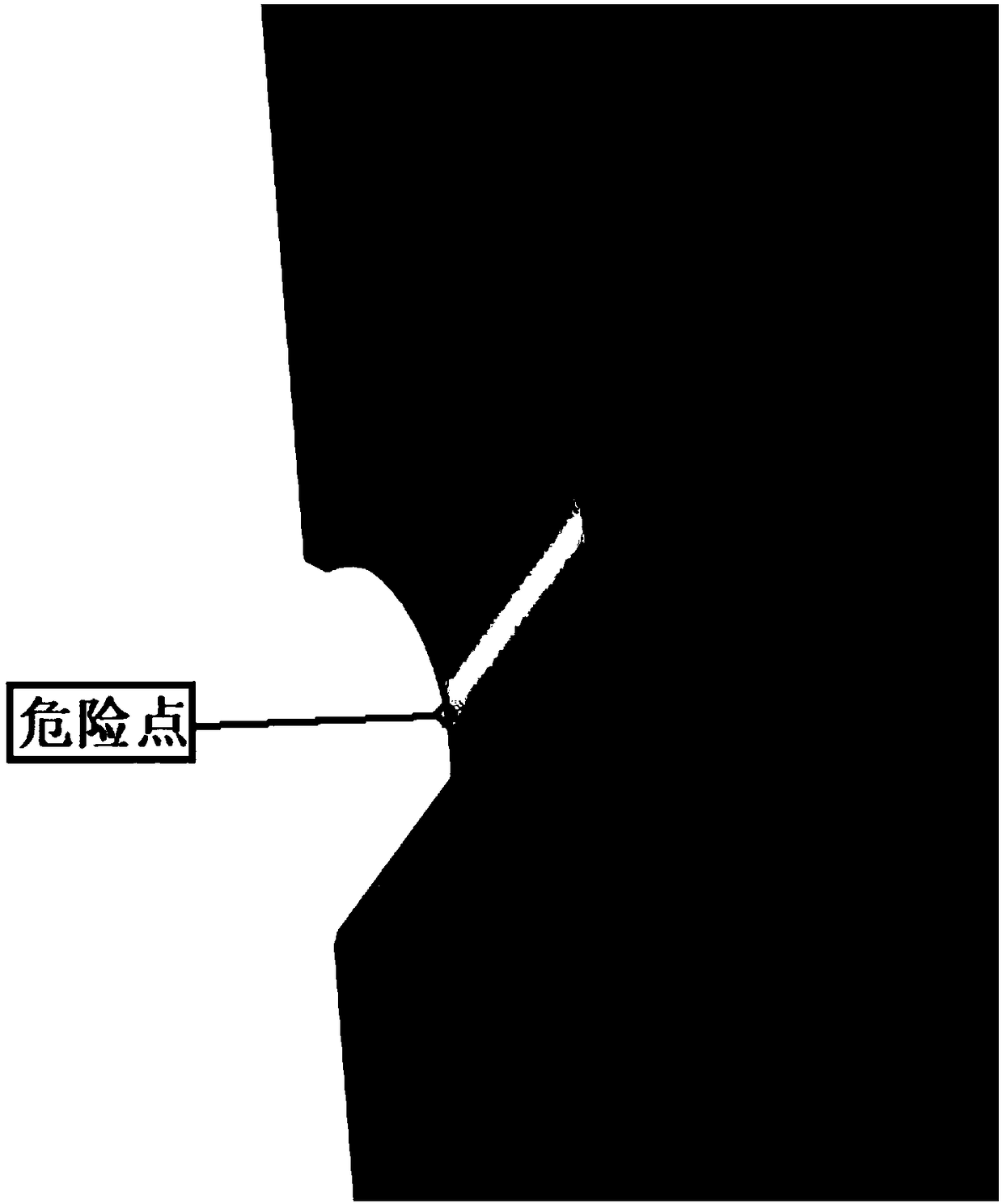

[0034] Step 1): Use the finite element method to determine the position of the dangerous point of the key part of the structure, and at the same time calibrate the position of the strain sensor to be installed in the actual structure. The No. 1 sensor is installed on the back facing the dangerous point, and the No. 2 sensor is installed on the No. 1 On the same side as the sensor, the distance from the No. 1 sensor needs to refer to the actual thickness of the aircraft structural part. Ensure that the distance between the two sensors...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com