Pressure maintaining check valve

A check valve and check technology, applied in the direction of control valves, valve devices, functional valve types, etc., can solve problems such as increasing the outlet, affecting the reaction speed of the valve disc, and damaging sensitive equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with accompanying drawing:

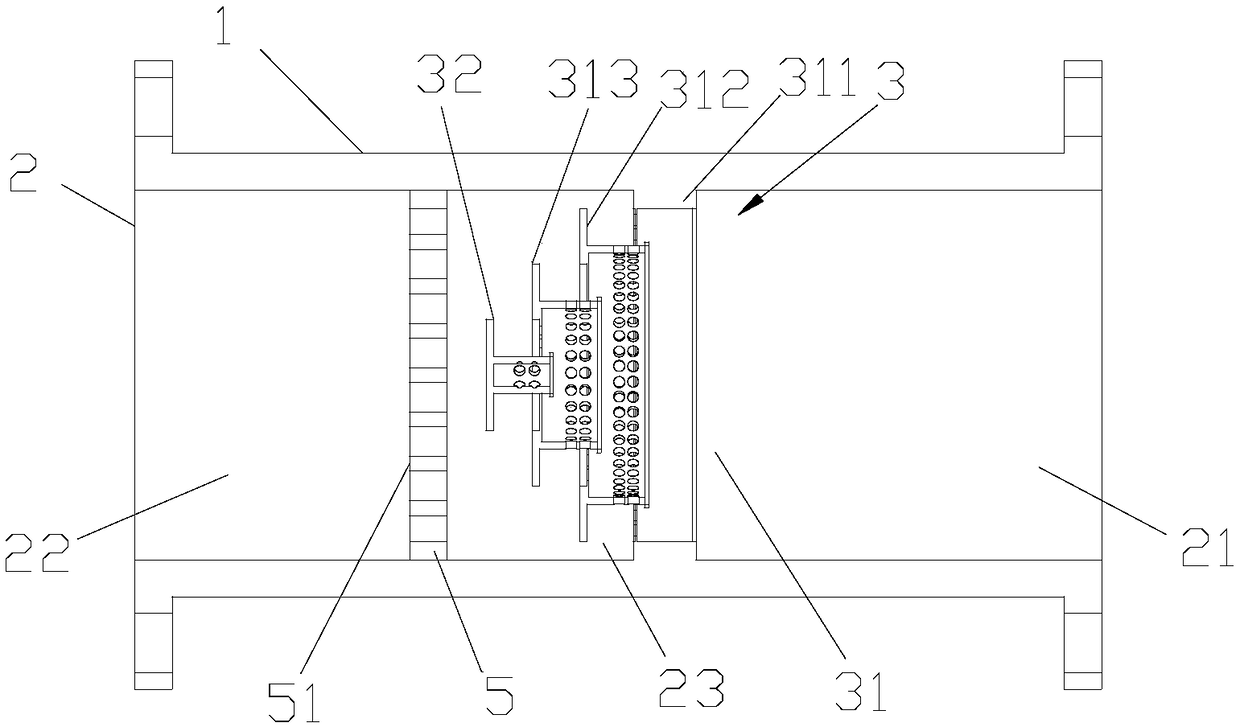

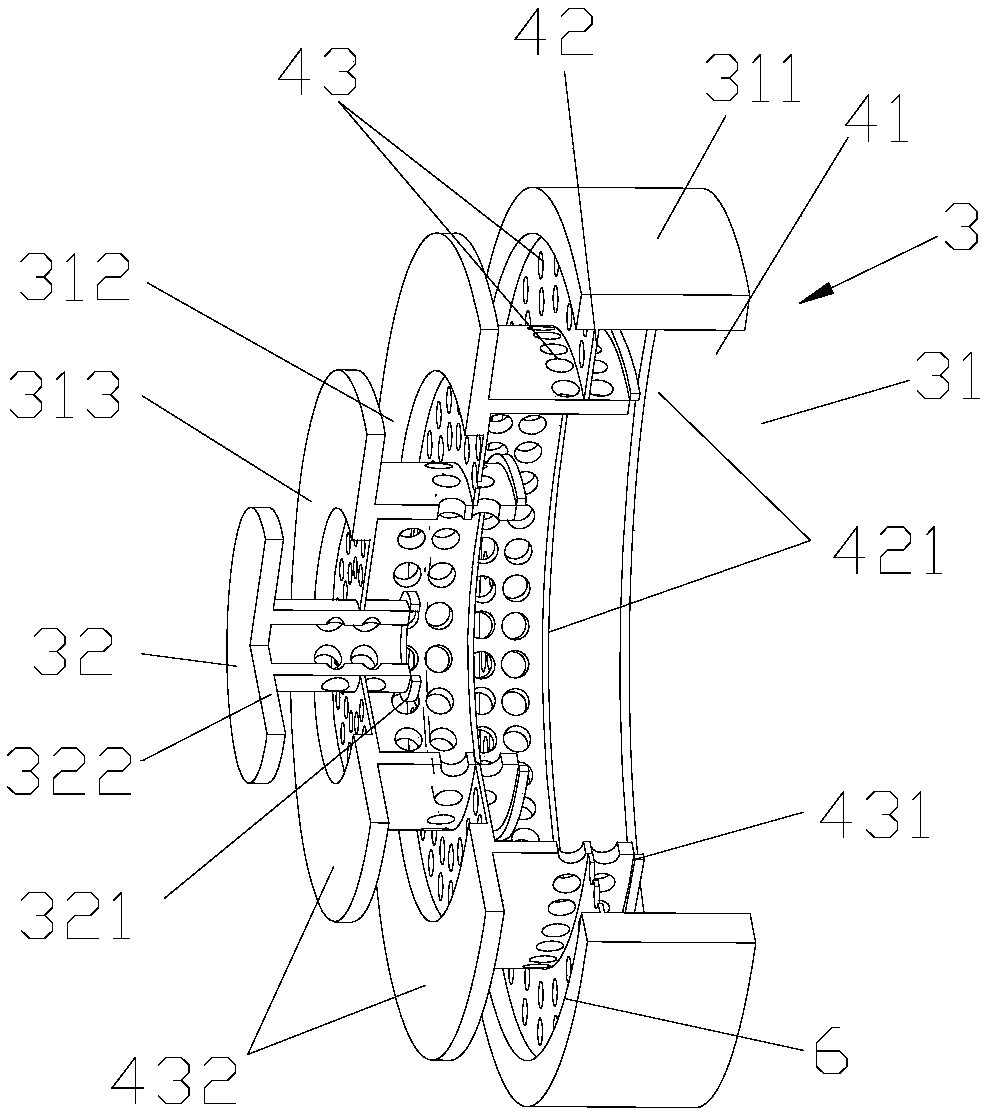

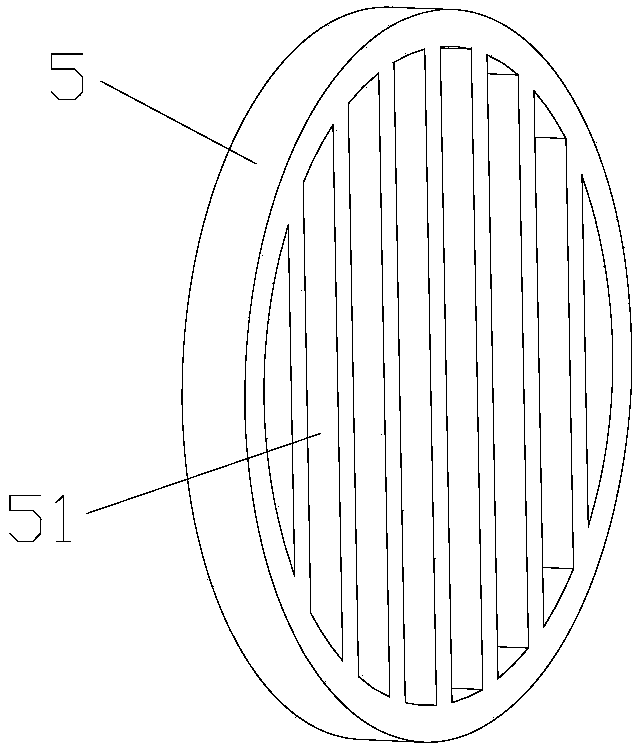

[0032] Such as figure 1 , 2 , 3, and 4, this embodiment includes a valve body 1 with a fluid channel 2, the fluid channel 2 includes an inlet flow channel 21, a valve core flow channel 23 and an outlet flow channel 22, and the valve core flow channel 23 is installed with Spool assembly 3. The spool assembly 3 includes: a non-return sleeve 31 (cylindrical) which is sequentially socketed. The sleeve 312 and the three-stage non-return sleeve 313 (equivalent to the last-stage non-return sleeve) are composed. The non-return sleeves 31 of each stage are located on the same axis as the fluid channel 2 . The non-return sleeves 31 at each level include an open end 41 corresponding to the direction of the inlet flow channel 21, and a closed end 42 (sealed circular surface) corresponding to the direction of the outlet flow channel 22, where the closed end 42 is perpendicular to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com