Coupling agent sealing and collecting device for control rod drive mechanism ultrasonic inspection

A driving mechanism, ultrasonic inspection technology, applied in the direction of material analysis, measurement device, instrument, etc. using sonic/ultrasonic/infrasonic waves, which can solve the problem of poor airbag sealing, inability to completely empty the couplant, and the connection between the airbag and the shell. Air leakage and other problems, to achieve the effect of easy coupling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

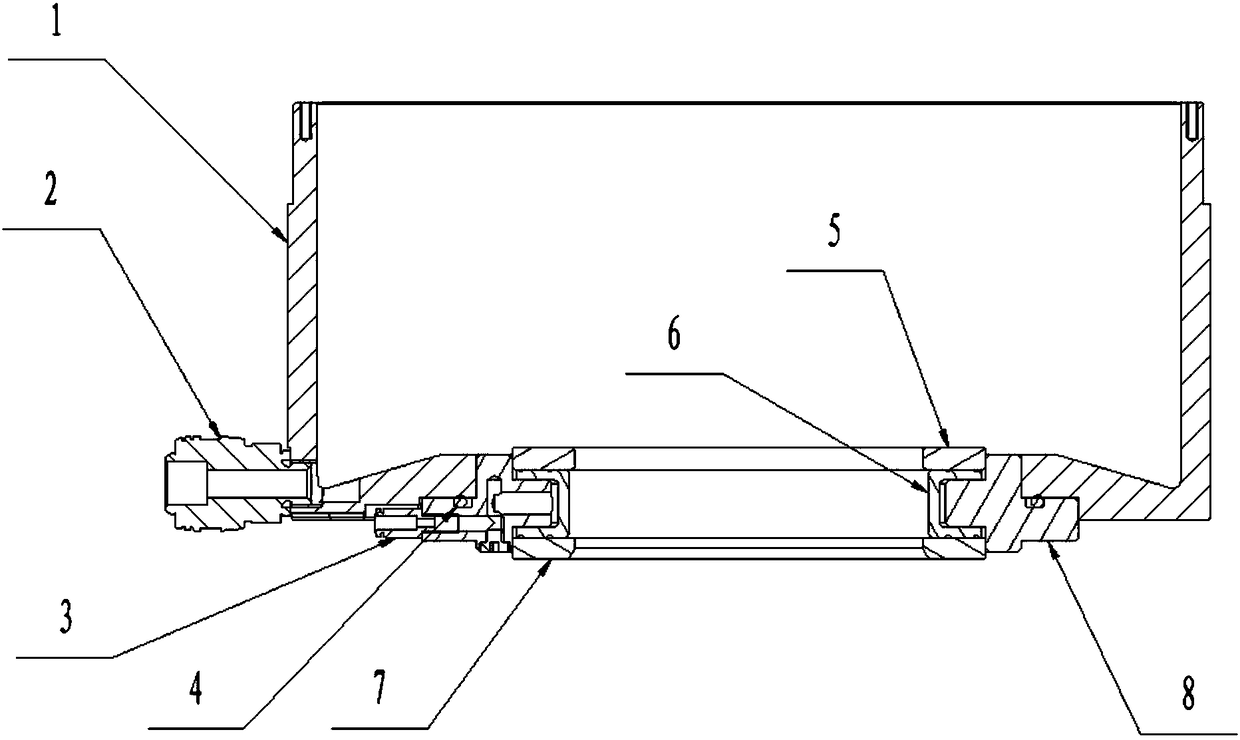

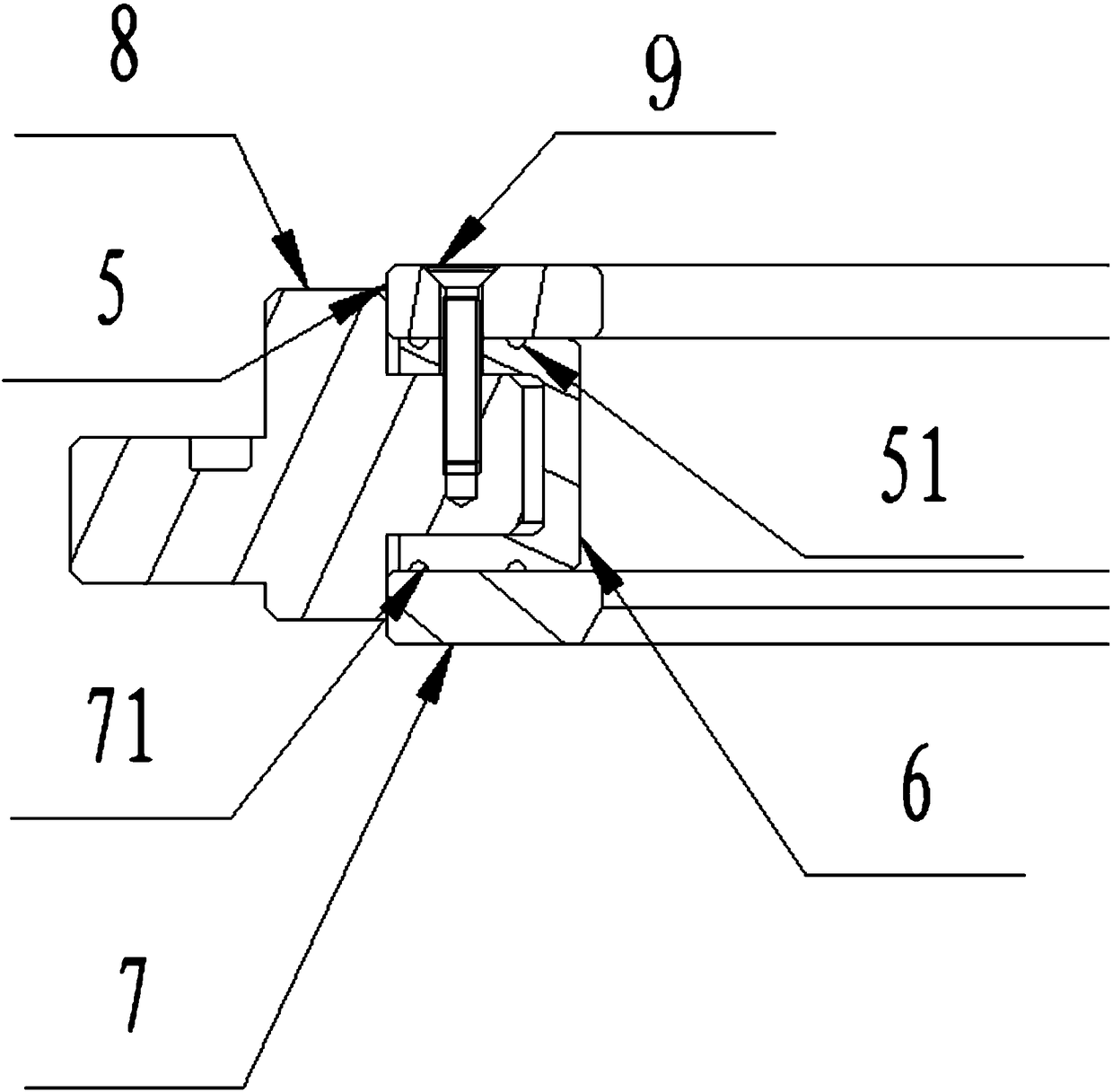

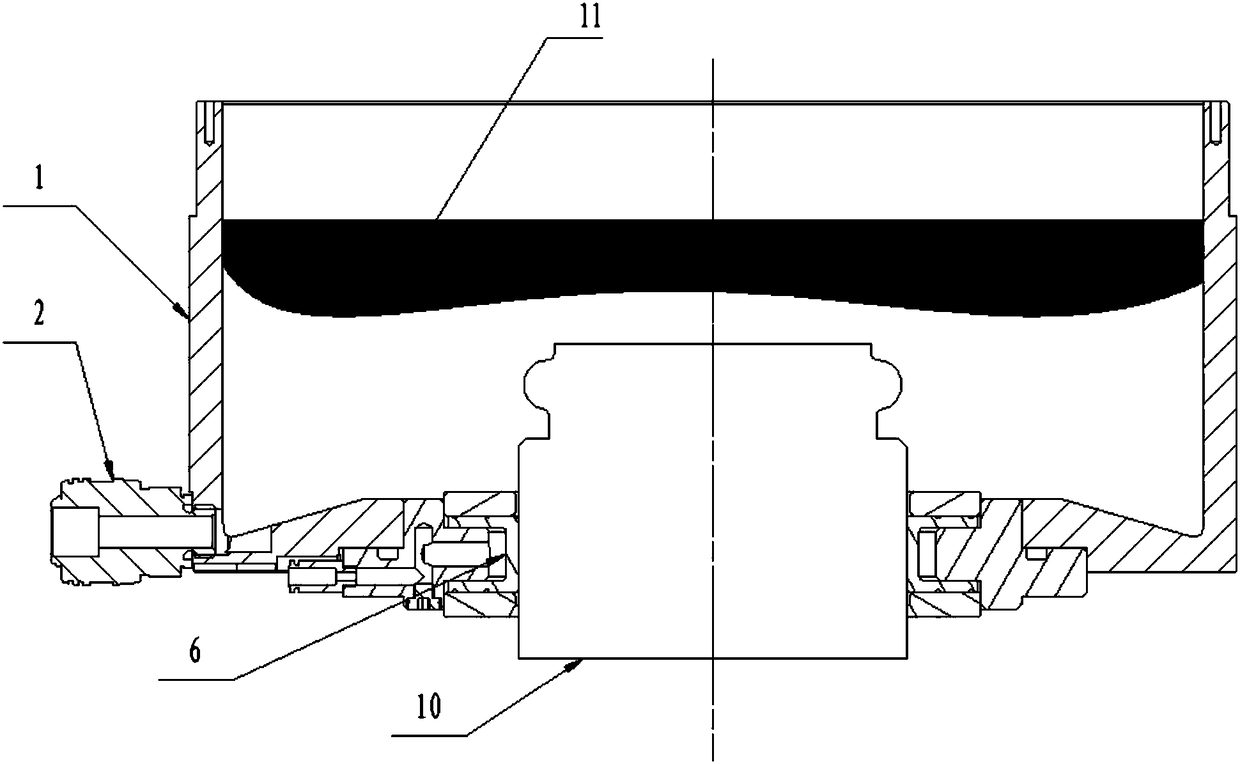

[0026] Such as figure 1 , figure 2 As shown, the present invention is a couplant seal collection device for ultrasonic inspection of the control rod drive mechanism, including a housing 1, a couplant inlet and outlet joint 2, an airbag inflation joint 3, an O-ring 4, and an airbag upper pressure plate 5 , airbag 6, airbag lower pressure plate 7, airbag connecting block 8, airbag screw 9.

[0027] The housing 1 is a hollow cylindrical structure as a whole, including side walls and a bottom with a through hole in the center. The bottom is designed as a special geometric shape, and the upper surface is slope-shaped with a high middle and low surroundings, which is beneficial for the coupling agent 11 to flow from a high place to a low place under the action of gravity; Form a sealed connection.

[0028] The bottom of the side wall of the shell 1 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com