Novel multichannel fiber array and manufacturing method thereof

A multi-channel, fiber count technology, applied in light guides, optics, optical components, etc., can solve the problems of unreachable optical performance indicators, high product prices, and inability to improve the yield rate, etc., to improve multiple optical performance indicators and compact structure , the effect of uniform spacing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to further reveal the technical solutions of the present invention, the implementation manners of the present invention will be described in detail in conjunction with the accompanying drawings.

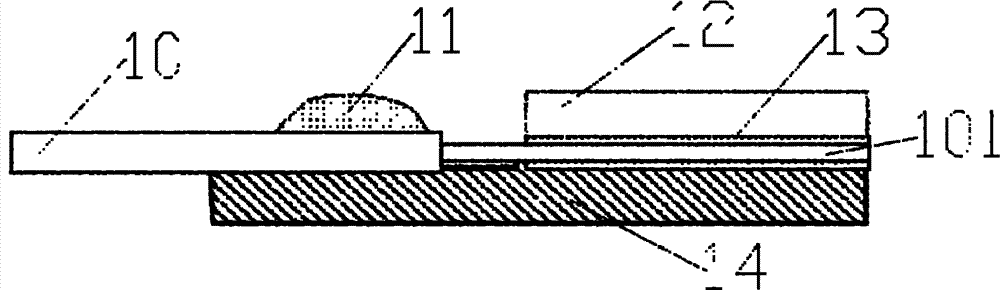

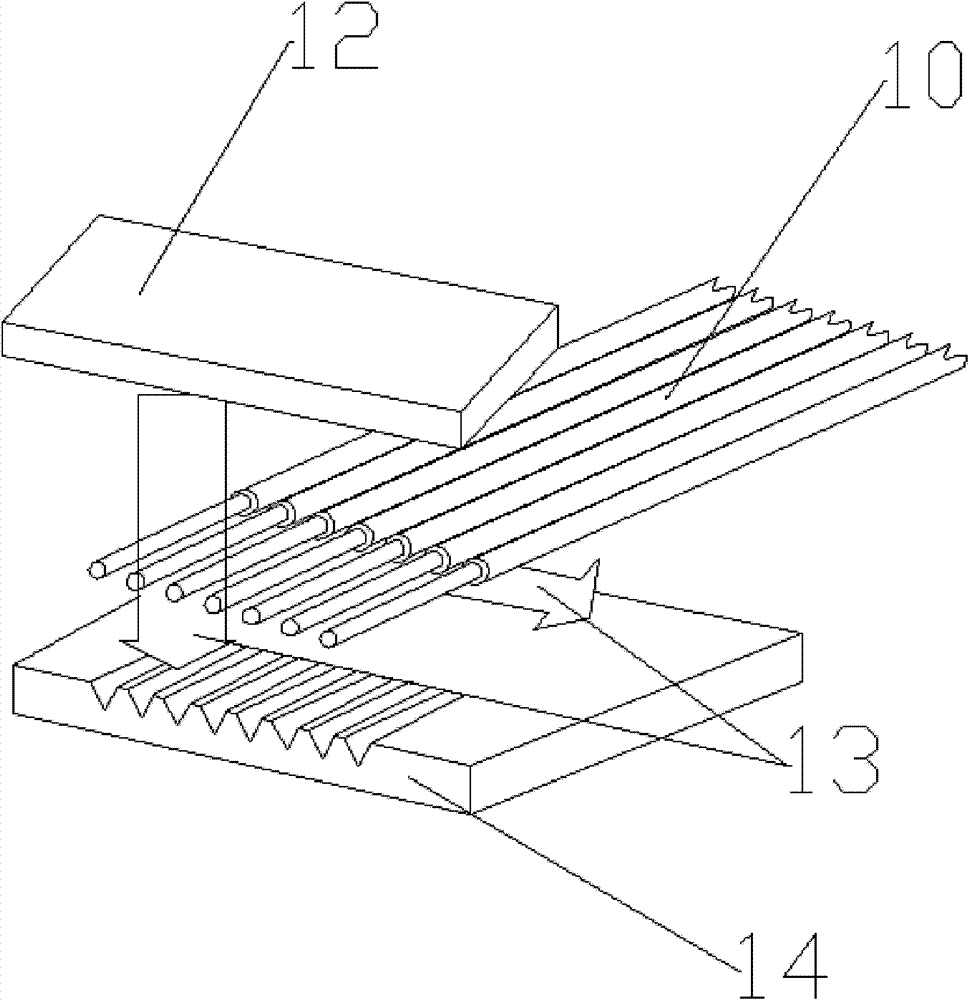

[0026] figure 1 It is a schematic diagram of the overall structure of the novel multi-channel optical fiber array and its manufacturing method of the present invention, figure 2 It is a schematic diagram of the exploded structure of the novel multi-channel optical fiber array and its manufacturing method of the present invention, which includes: a multi-core optical fiber ribbon 10; in addition, the optical fiber array also includes: an optical fiber ribbon adhesive 11, a cover plate 12, an optical fiber core adhesive agent 13, V-shaped groove substrate 14; wherein, the multi-core optical fiber ribbon 10 is fixed on the V-shaped groove substrate 14 by an optical fiber ribbon adhesive 11; the cover plate 12 covers the optical fiber core 101 and The optical fiber core...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com