Wire stranding machine straightener

A straightening machine and stranding machine technology, applied in the field of cable straightening equipment, can solve problems such as precision defects, inconvenient operation, and inconvenient adjustment operation, so as to reduce straightening torsional torque, reduce straightening errors, and ensure straightening The effect of straight precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make those skilled in the art better understand the technical scheme of the present invention, the present invention will be further described below in conjunction with embodiment:

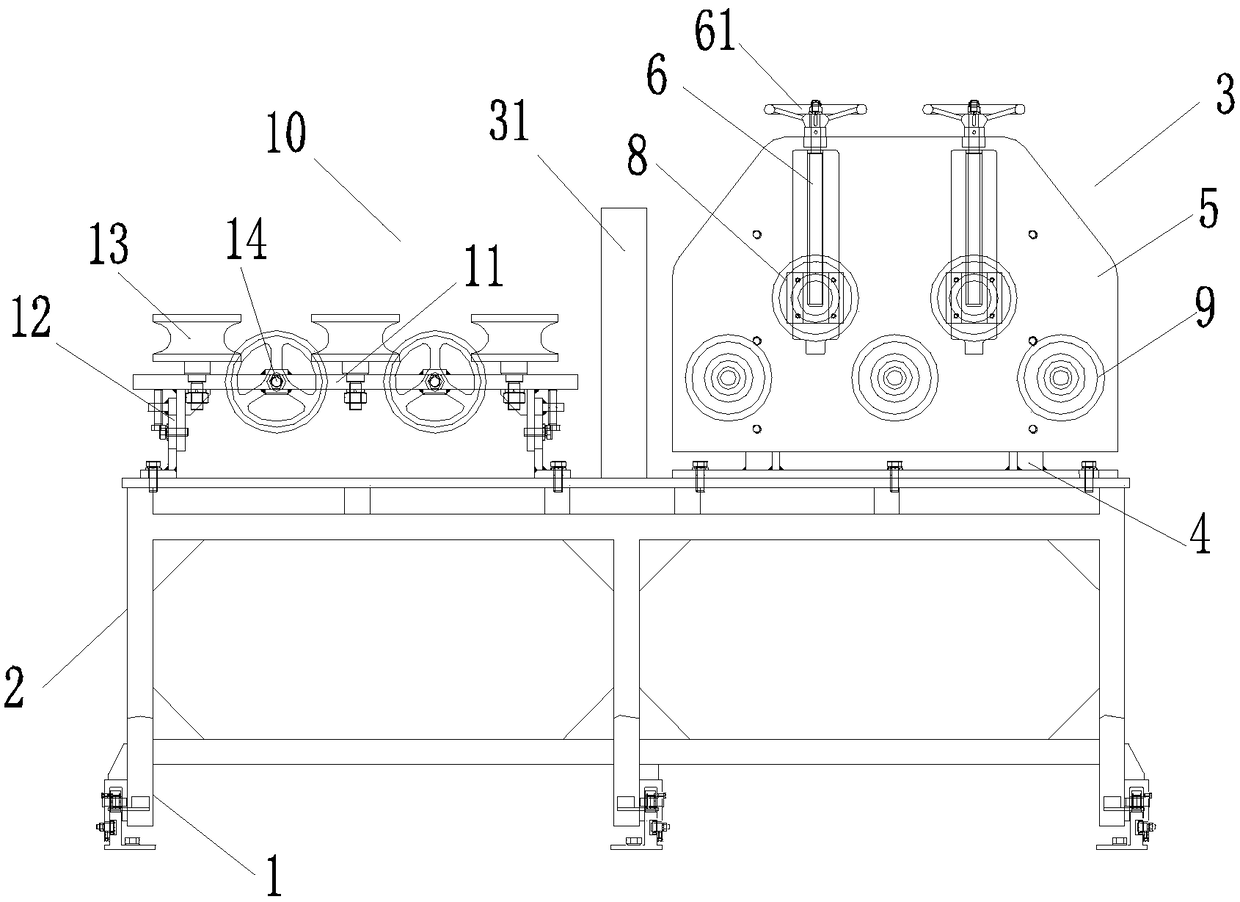

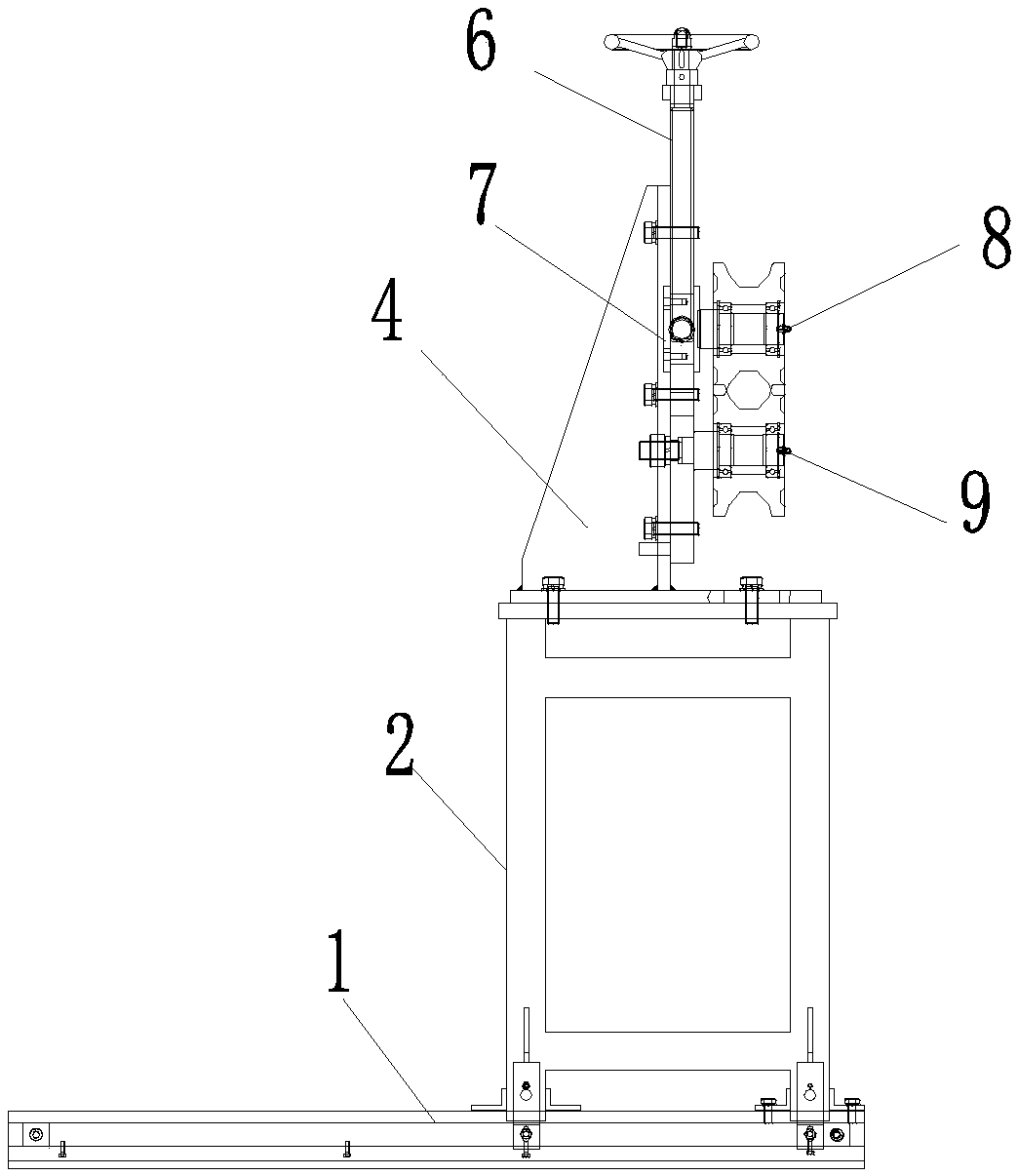

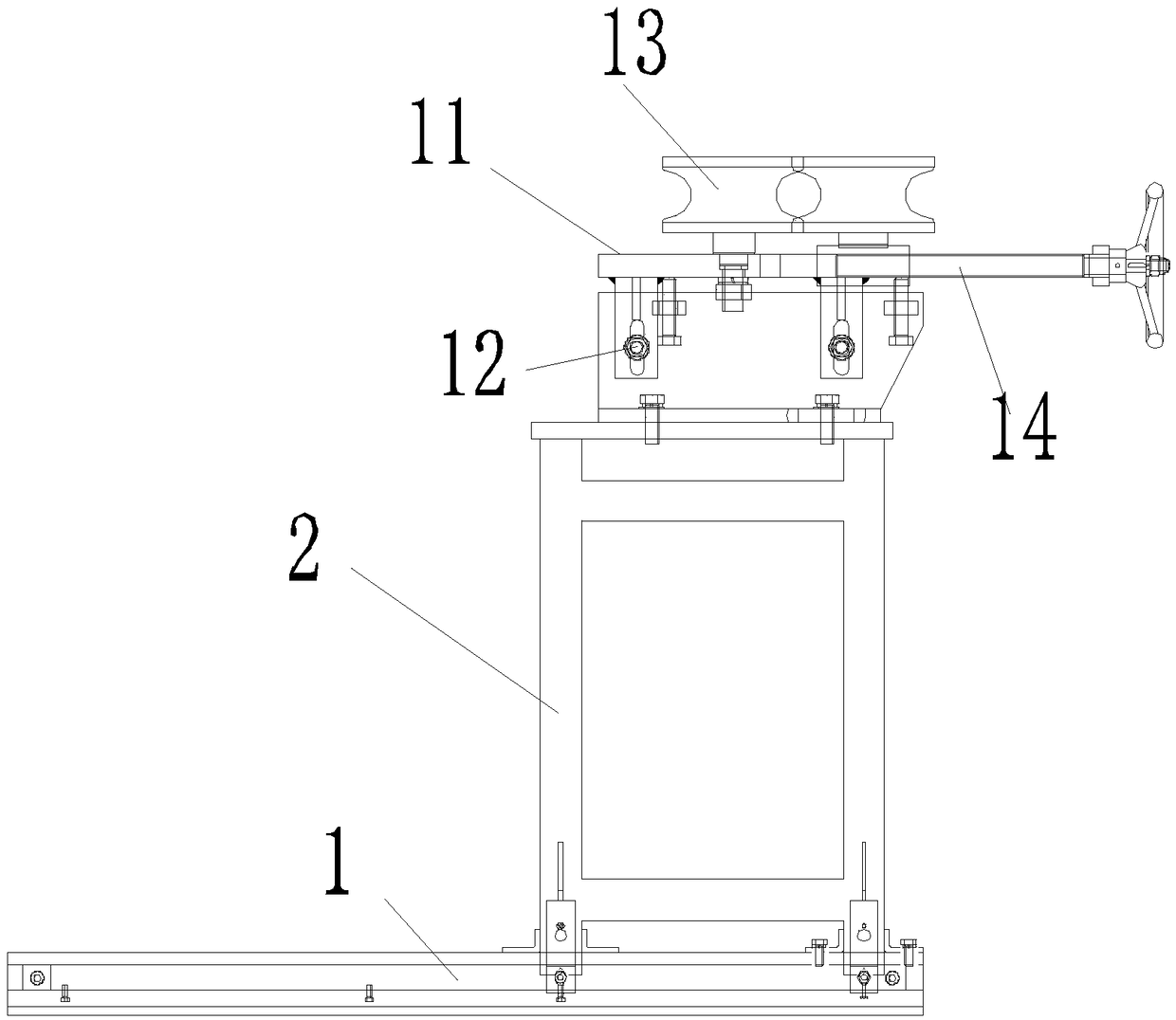

[0019] A straightening device for a wire stranding machine, comprising a guide rail 1 fixed on the ground by anchor bolts, a base 2 is movable on the guide rail 1, and one end of the upper surface of the base 2 is fixed by a bolt with a vertical Straightening device 3, described vertical straightening device 3 comprises support 4, and described support 4 is provided with straightening panel 5, and described straightening panel 5 is movably connected with multiple sets of screw rods 6, and multiple The bottom of the set of screw rods 6 is connected with a sliding guide wheel assembly 8 through a fixed base 7, and a plurality of sets of fixed guide wheel assemblies 9 are fixed on the bottom side of the alignment panel 5. The vertical alignment One side of the straightening device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com