Printed circuit board manufacturing method and printed circuit board

A printed circuit board and manufacturing method technology, applied in the directions of printed circuit components, multilayer circuit manufacturing, etc., can solve the problems of human target selection errors, alignment errors, product scrap, etc., to achieve high reliability and reduce alignment errors. , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

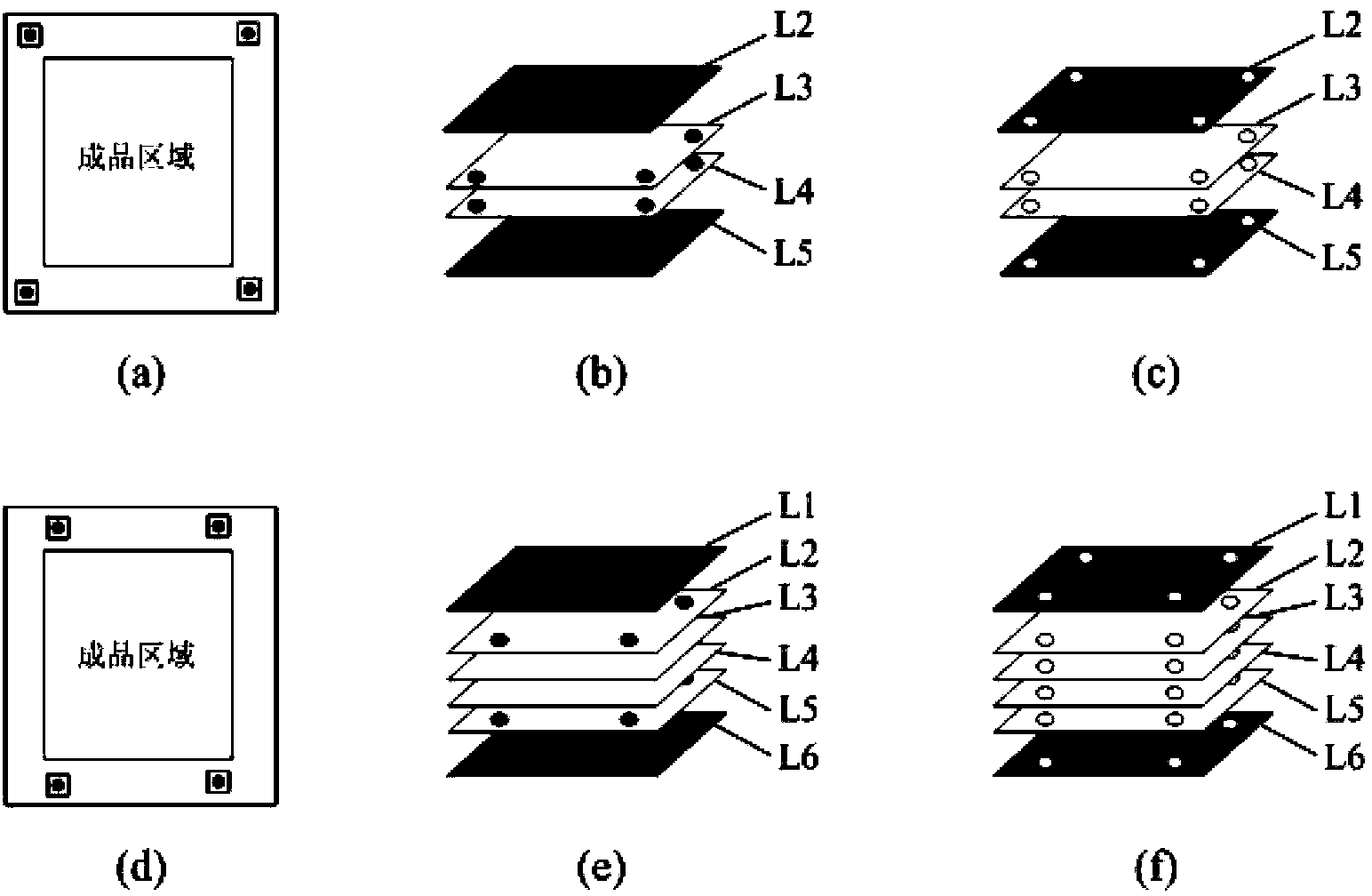

[0062] Such as image 3 As shown, in this embodiment, the substrate adopts a double-sided substrate, and the printed circuit board produced is a six-layer HDI printed circuit board, and two layers of build-up layers are respectively arranged on both sides of the double-sided substrate (that is, a total of four layers of build-up layers) . The manufacturing method of this six-layer HDI printed circuit board comprises the steps:

[0063] A1. A group of first targets are respectively set at the three corners of the double-sided substrates L3 and L4, and a pair of first targets is set at the corners of the substrates where the first target is not set. A secondary target for bit benchmarks.

[0064] In this step, the first target, the second target used as an alignment reference for the build-up layer adjacent to the double-sided substrate, and the pattern on the substrate are simultaneously formed on the double-sided substrate by pattern transfer superior. At this time, the f...

Embodiment 2

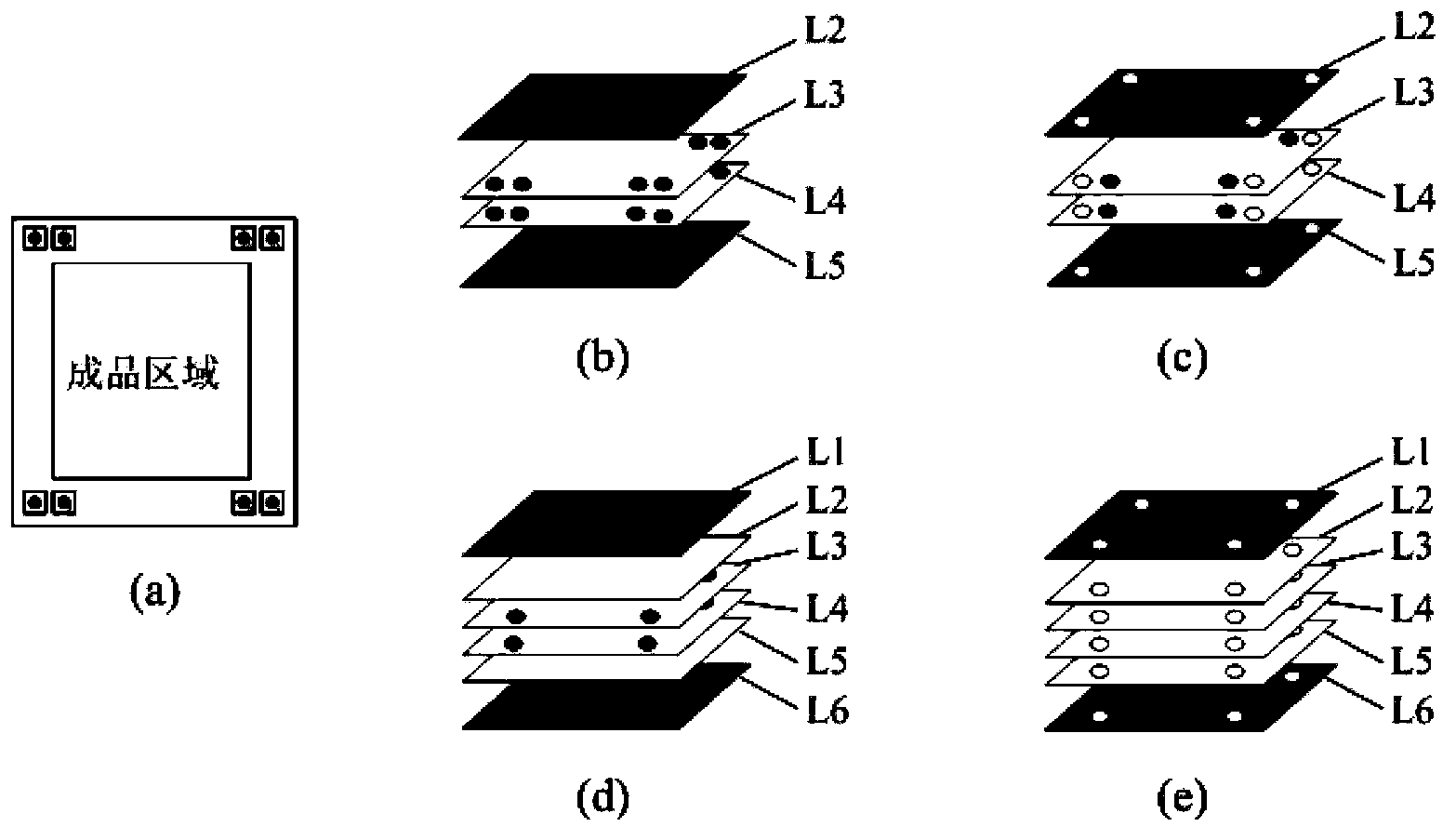

[0085] The printed circuit board in this embodiment is a seven-layer HDI printed circuit board. If a double-sided substrate is also used, the number of build-up layers to be set is five, and the five-layer build-up layers are asymmetrically distributed on both sides of the double-sided substrate. , for example, a double-sided substrate with a three-layer buildup on one side and a two-layer buildup on the other side. The manufacturing method of this seven-layer HDI printed circuit board comprises the following steps:

[0086] A1. A set of first targets are respectively arranged on the double-sided substrates, and a second target used as an alignment reference for a build-up layer adjacent to the double-sided substrates is arranged at a corner of the substrate where no first targets are arranged.

[0087] In this step, when the number of build-up layers to be set is asymmetrically distributed on both sides of the substrate, the number of first targets in the group of first targ...

Embodiment 3

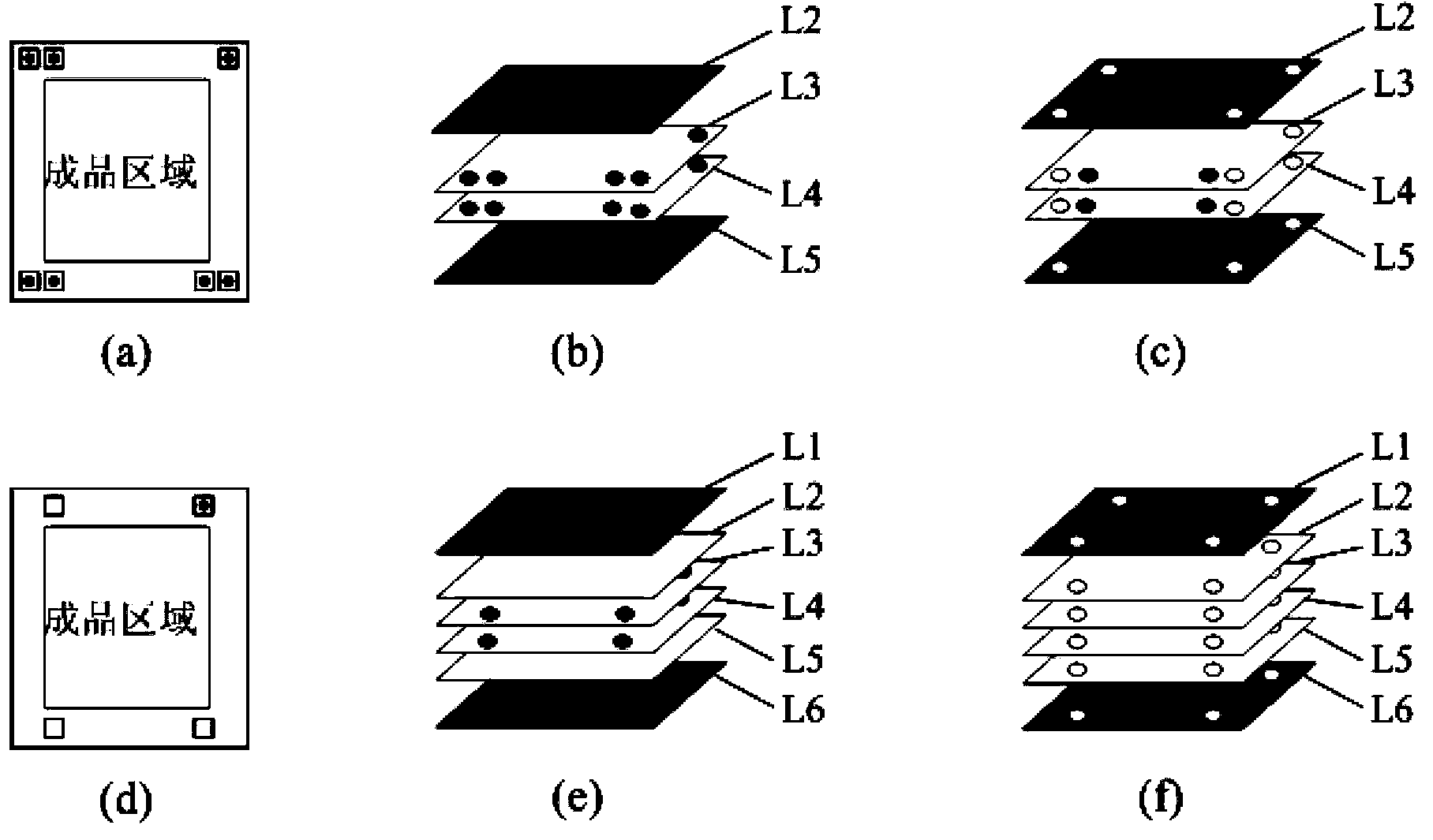

[0099] The difference between this embodiment and Embodiments 1 and 2 is that the printed circuit board of this embodiment is laminated with build-up only on one side of the double-sided substrate, or the substrate itself is a single-sided substrate, and the build-up is laminated only on one side. .

[0100] In this embodiment, after each build-up layer is pressed on the side of the substrate where the build-up layer needs to be pressed, the second target on the substrate or the build-up layer and the unused target corresponding to the second target on the substrate and the same build-up layer The used first target is used as a reference to form a target hole on one of the laminated build-up layers; and using the target hole as an alignment reference, pattern transfer is performed on one of the laminated build-up layers until completion Pattern transfer of all buildup layers on one side of the substrate.

[0101] In this embodiment, the specific steps of the printed circuit b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com