Quick clamping and alignment method and fixture for milling arc segments of stationary blade grid

A technology of milling processing and static blade cascade, which is applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc. Easy operation, wide application range, convenient operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

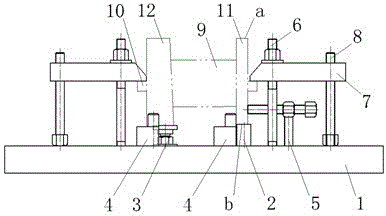

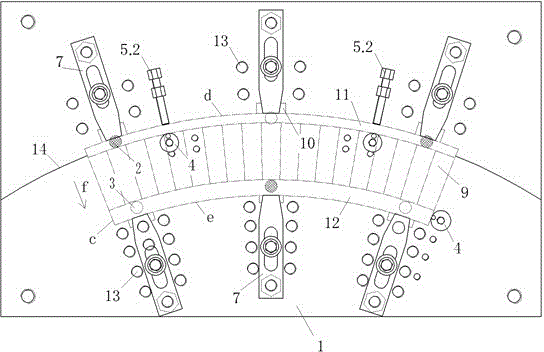

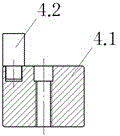

[0042] Based on the idea of fast clamping and aligning for the milling process of the arc section of the stationary blade cascade described above, the fast clamping and aligning fixture for the milling process of the arc section of the stationary blade cascade in this embodiment includes a plate body 1 (a square plate with a size of 1200mm×700mm×50mm ), 3 spacers A2 (a cylinder with a diameter of 60mm and a height of 50mm) and 3 height-adjustable spacers B3 (adjustable around 50mm in height) with fixed and consistent heights; The positioning mechanism 4 for positioning the grid arc segment 9 in the radial direction f and the side end surface c, the radial tightening mechanism 5 for radially tightening the stationary blade cascade arc segment 9, and the press-fitting mechanism for pressing and installing the stationary blade cascade arc segment 9 .

[0043] In this embodiment, the positioning mechanism 4 is mainly used for positioning the radial direction f and the side end s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com