Great-size touch screen panel joint device and method

A technology of laminating device and touch screen, which is applied in lamination devices, chemical instruments and methods, layered products, etc., can solve the problems of easy generation of air bubbles and difficulty in panel lamination and alignment, and achieves improved production efficiency and simple structure. , the effect of reducing technical requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the content of the present invention more obvious and understandable, further description will be made below in conjunction with the accompanying drawings and specific embodiments.

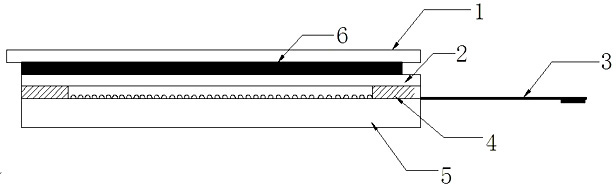

[0029] combine figure 1 Taking the conventional resistive touch screen currently on the market as an example, the main body of the touch screen includes the upper electrode 2 of the touch screen, the output terminal 3 of the touch screen, the key sheet 4, the lower electrode 5 of the touch screen, etc., and the panel 1 is attached to the main body of the touch screen through the optical adhesive layer 6 .

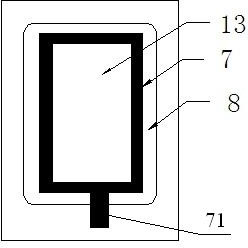

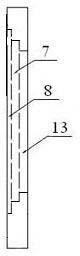

[0030] In order to make up for the shortcomings of the large-size touch screen panel bonding technology in the prior art, the present invention provides a large-size touch screen panel bonding device, which includes a bonding mold, such as figure 2 and image 3 As shown, the bonding mold includes a main body groove 7 and a panel groove 8 which can be processed by a mil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com