Battery cell welding method, device and electronic equipment

A welding equipment and welding method technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problem of low welding efficiency, achieve the effect of high automation efficiency and improve welding reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] After investigation, it is found that most of the existing methods for welding electric cores use manual welding, and the welding efficiency is not high.

[0048] The defects in the solutions in the above prior art are all the results obtained by the inventor after practice and careful research. Therefore, the discovery process of the above problems and the solutions to the above problems proposed by the embodiments of the present invention below , should be the inventor's contribution to the invention during the process of the invention.

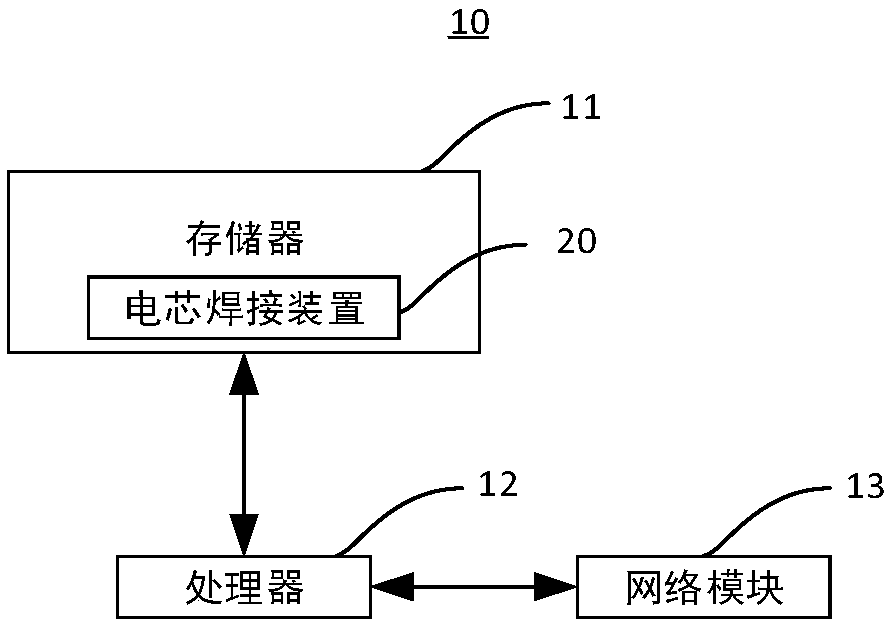

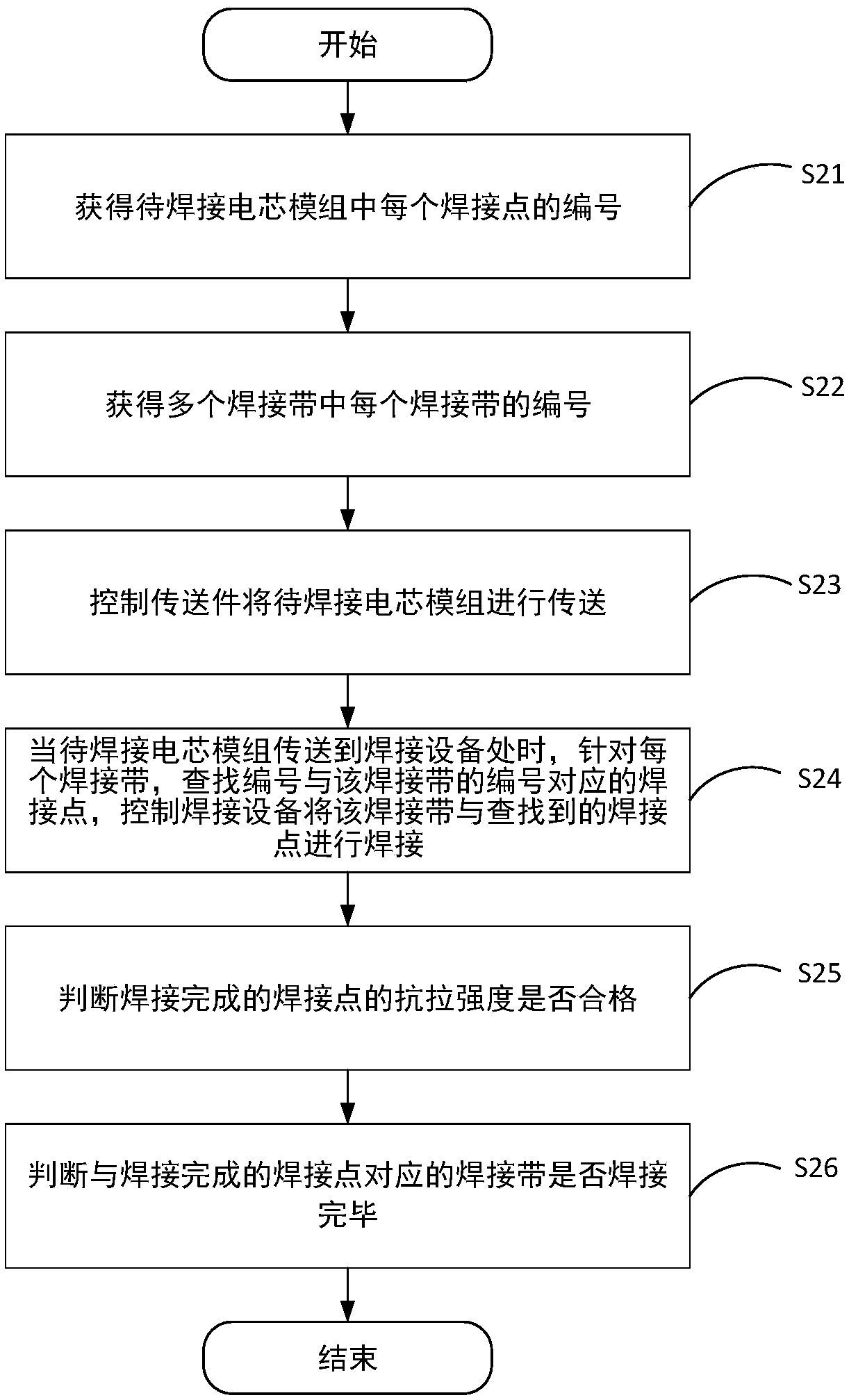

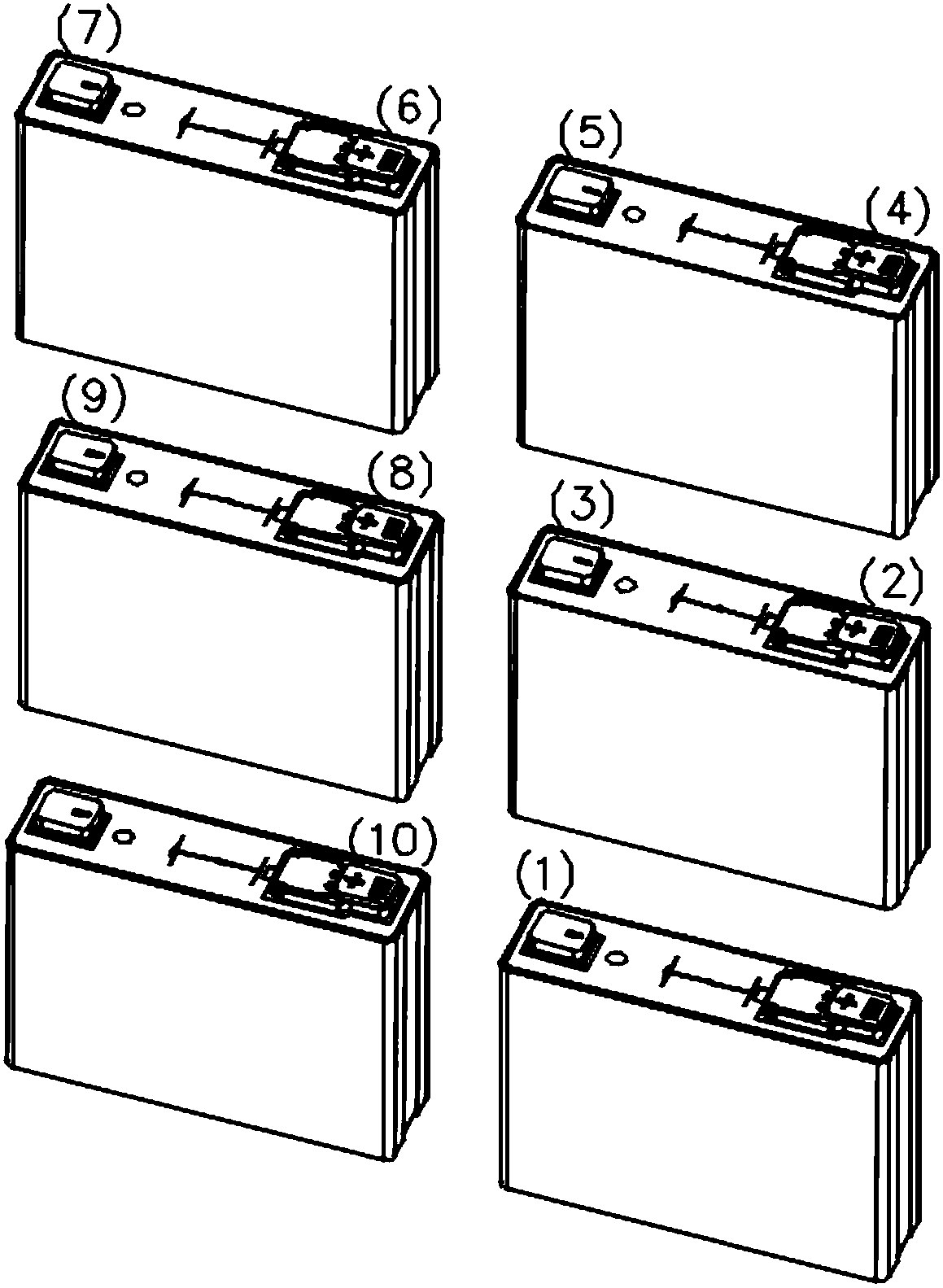

[0049] Based on the above research, the embodiments of the present invention provide a cell welding method, device and electronic equipment, which number the welding points and welding strips, and control the welding equipment to perform welding according to the corresponding numbers, with high automation efficiency.

[0050] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com