Sand classifying crushing and screening machine for civil engineering

A technology of civil engineering and sand screening machine, which is applied in the direction of separating solids from solids by air flow, sieving, solids separation, etc., which can solve the problems of insufficient classification and screening, low work efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

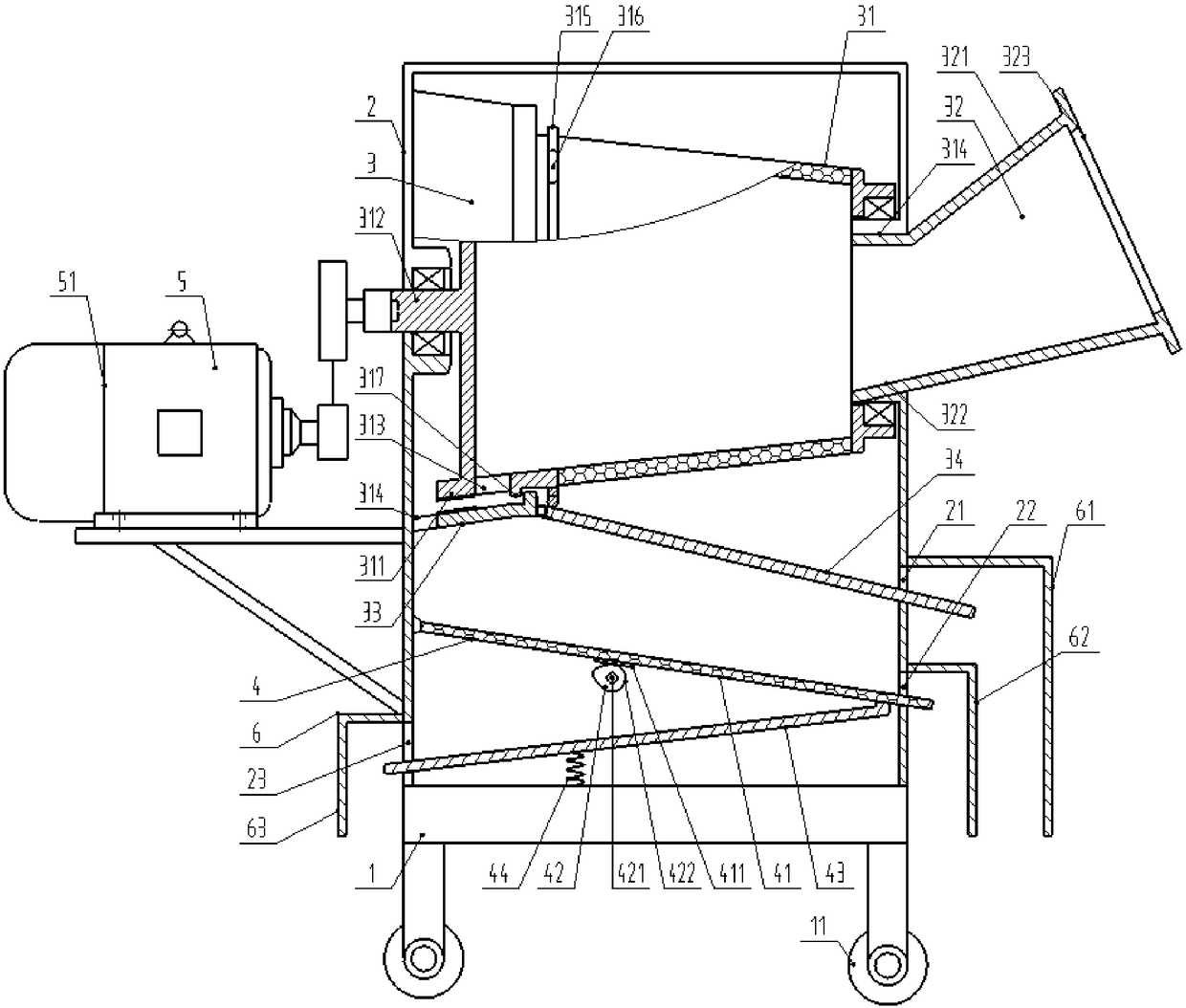

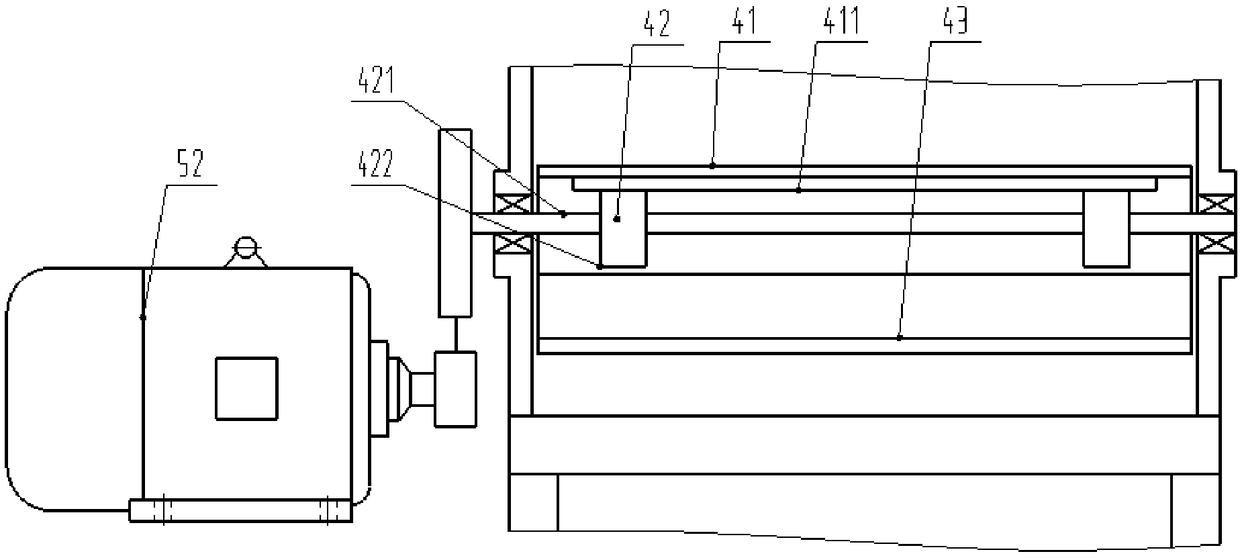

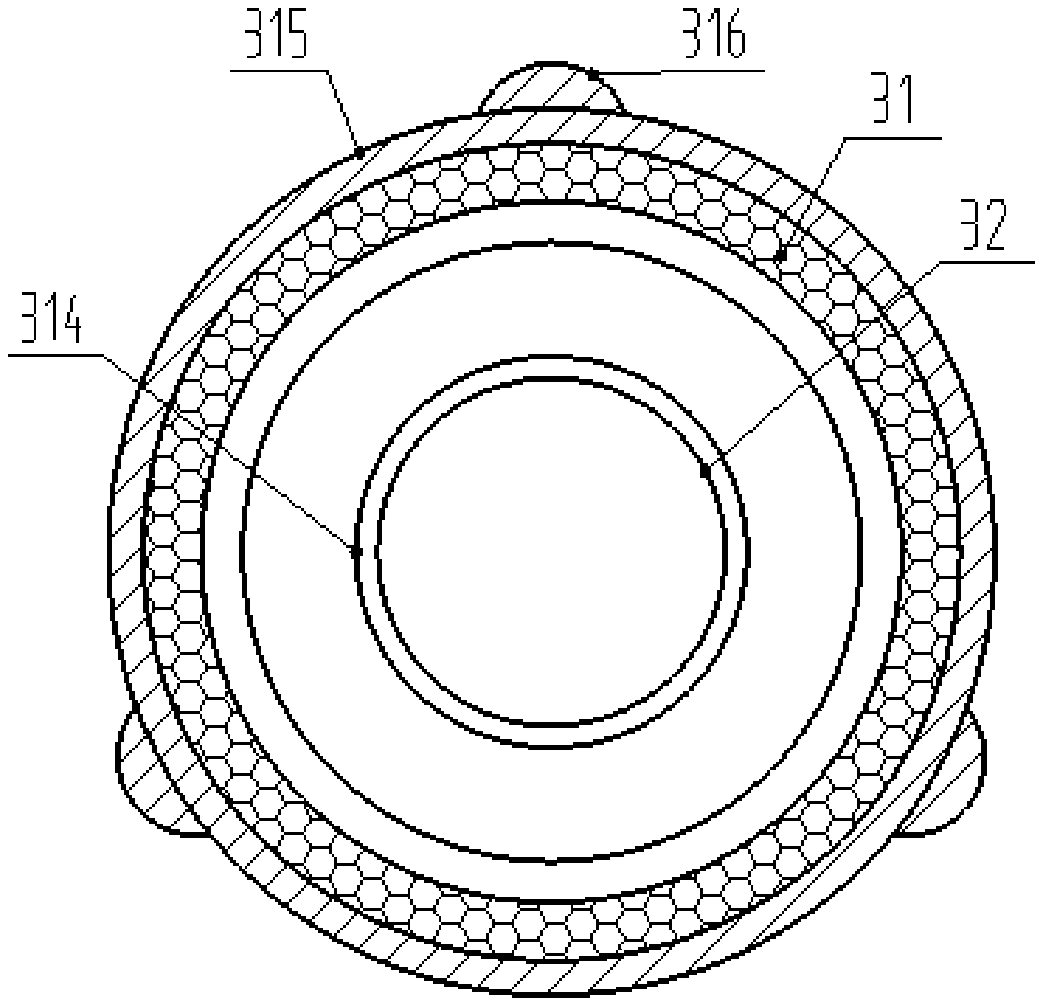

[0025] Such as Figure 1-3 As shown, a sorting sand screening machine for civil engineering includes a chassis 1, a casing 2, a primary crushing and screening assembly 3, a secondary screening assembly 4 and a drive mechanism 5, and the casing is arranged on the chassis , the primary crushing and screening assembly includes a screen cylinder 31, a feed hopper 32, a grinding cylinder 33 and a first material guide plate 34, the screen cylinder is in the shape of a cone and is connected to the upper part of the inner cavity of the casing in a horizontal rotation, There is a frosted part 311 and a transmission part 312 extending out of the casing at the large end of the screen cylinder, and several material guide ports 313 are opened on the circumferential wall close ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com