Automatic metal net braiding machine

A knitting machine and metal mesh technology, applied in the field of metal mesh automatic knitting machines, can solve the problems of difficult product quality assurance, low production efficiency, and different weaving levels, so as to save manpower, improve product quality, and improve meshing efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

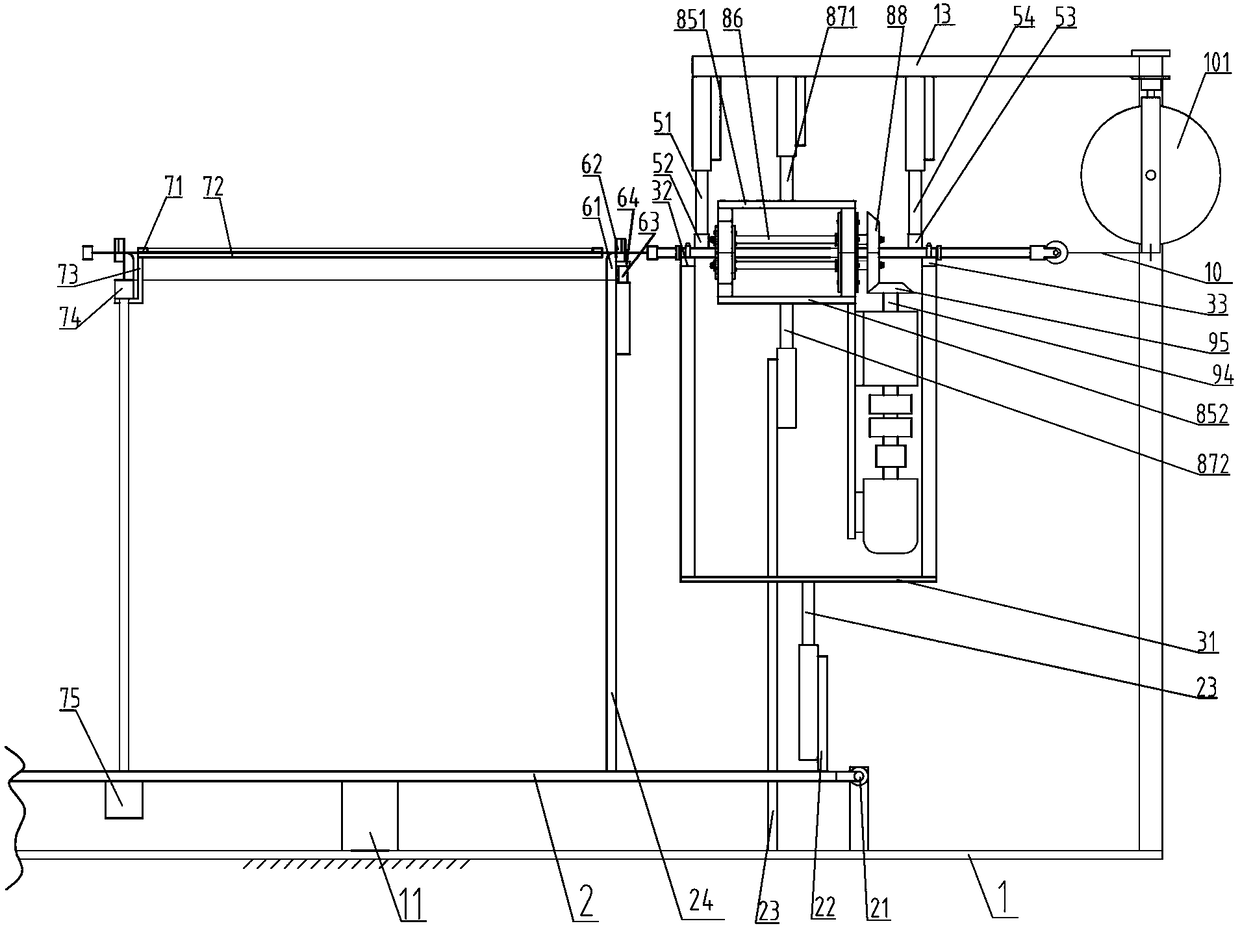

[0038] Figure 15 to Figure 20 It is a structural diagram of a split bearing in Embodiment 2 of the present invention. The split bearing 8 includes two semi-bearing structures that can be close to each other and connected symmetrically in a plug-in manner. Figure 15 Shown is a split bearing 8, Figure 16 Shown is a half bearing construction. The half-bearing structure includes a bearing outer ring, a bearing inner ring 82 and a cage 83 . The bearing inner ring 82 is in the shape of a semi-cylindrical body, and two through semicircular holes 821 are provided on its flat side. The axis of rotation is symmetrically arranged. The flat side surface of the bearing inner ring 82 is a plane diametrically opposite to the cylindrical surface of the bearing inner ring 82 , which is a cut surface of the bearing inner ring 82 from a complete cylinder to a half cylinder. The rotating shaft of the bearing inner ring 82 is the central axis of the cylindrical surface of the bearing inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com