Soil sample crushing device

A technology for broken samples and soil samples, applied in the field of field operation equipment, can solve problems such as time-consuming and laborious, and achieve the effects of simple operation, compact size and reasonable structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further explained below in conjunction with specific embodiments, but the present invention is not limited thereto.

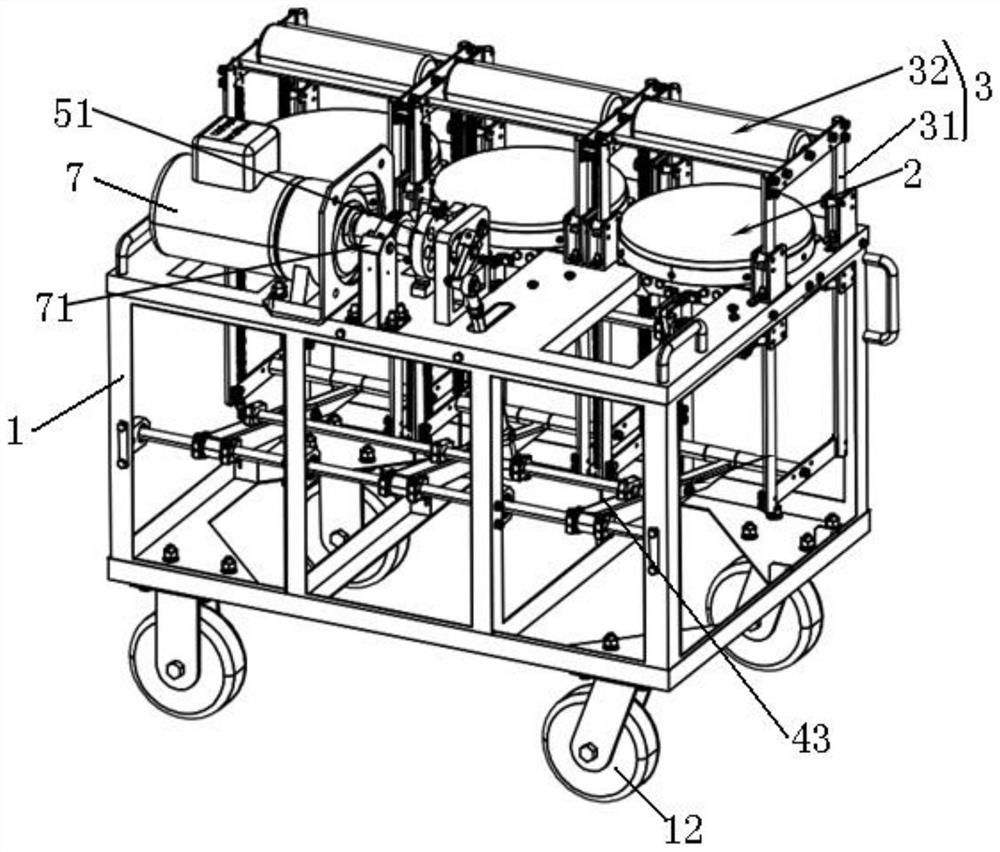

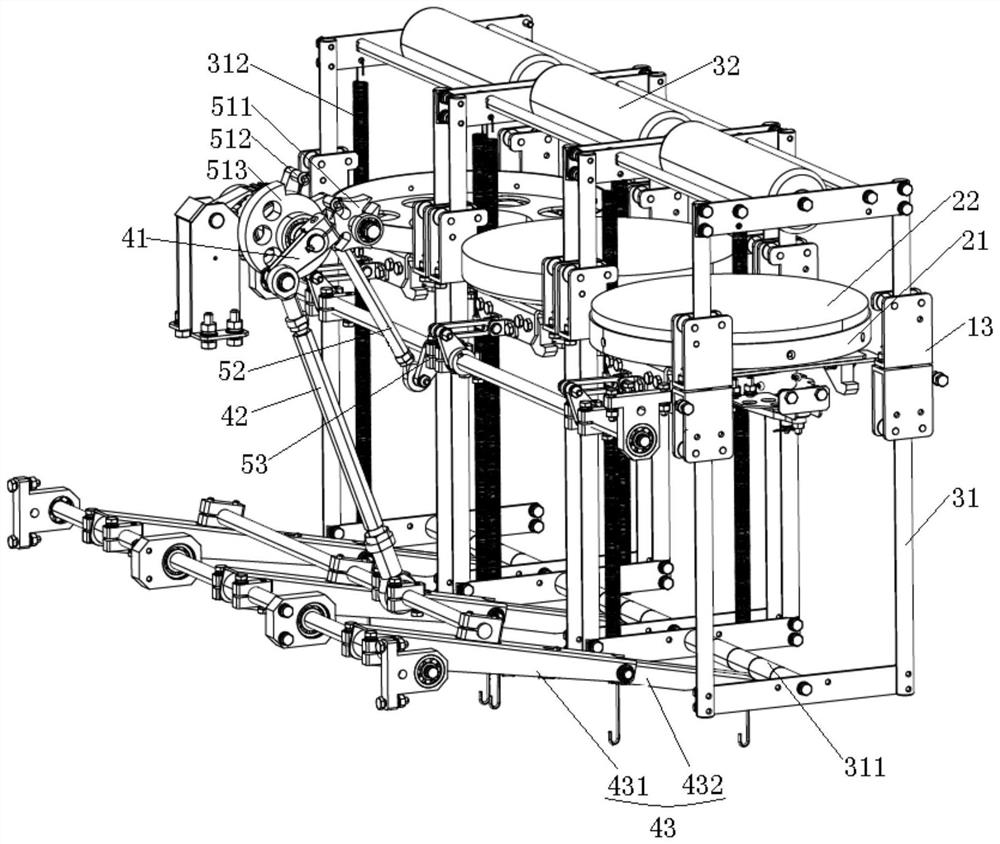

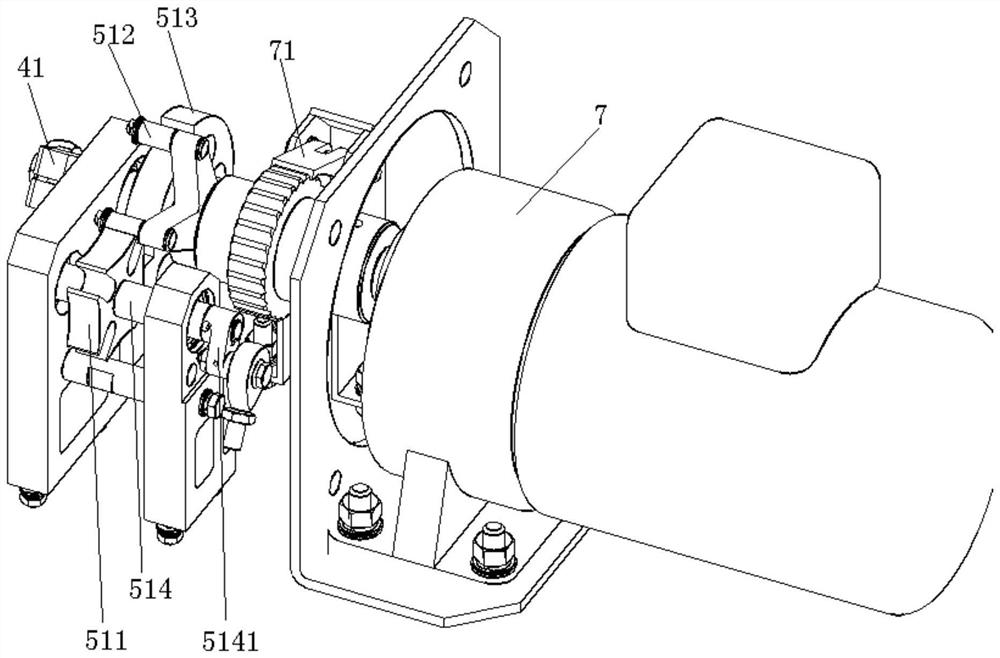

[0027] Such as Figure 1 to Figure 6 As shown, the present invention provides a soil sample crushing device, comprising: a frame 1, a crushing sample tray 2, a hammer pressing mechanism 3, a lifting mechanism, a push-pull mechanism and a rotating mechanism, wherein the crushing sample tray 2 is rotatably connected It is above the push-pull mechanism and can reciprocate back and forth along the frame 1 under the drive of the push-pull mechanism. When the broken sample tray 2 moves forward or backward, One-way rotation is completed under the action of the hammer pressing mechanism 3. The hammer pressing mechanism 3 includes a lifting frame 31 arranged on the frame 1 and a crushing hammer 32 installed on the top of the lifting frame 31. The lifting frame 31 can be Driven by the lifting mechanism, it rises along the frame 1, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com