Multi-level displacement transition mechanism

A transition mechanism, multi-level technology, applied in the direction of conveyor objects, household components, household appliances, etc., can solve the problems of poor product quality stability, low manual operation efficiency, high cost, and achieve good product quality stability, low cost, Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

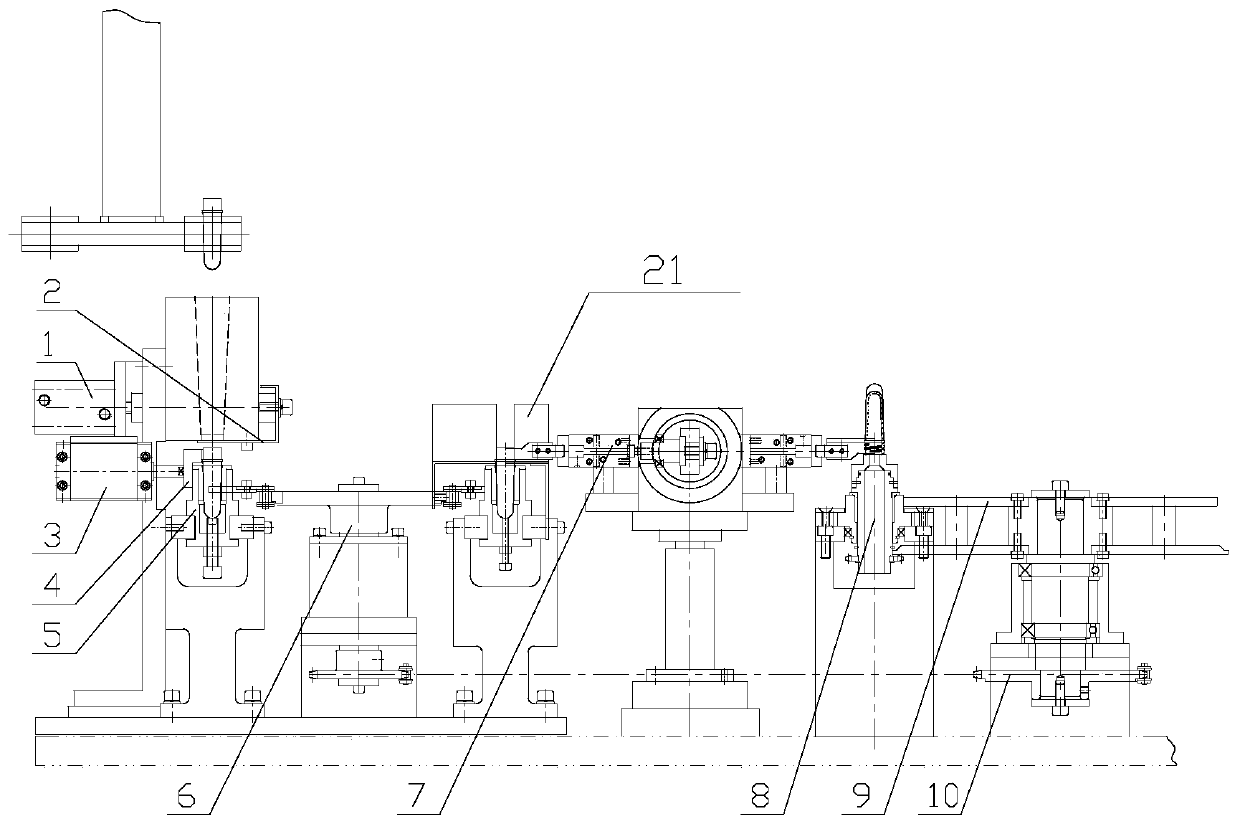

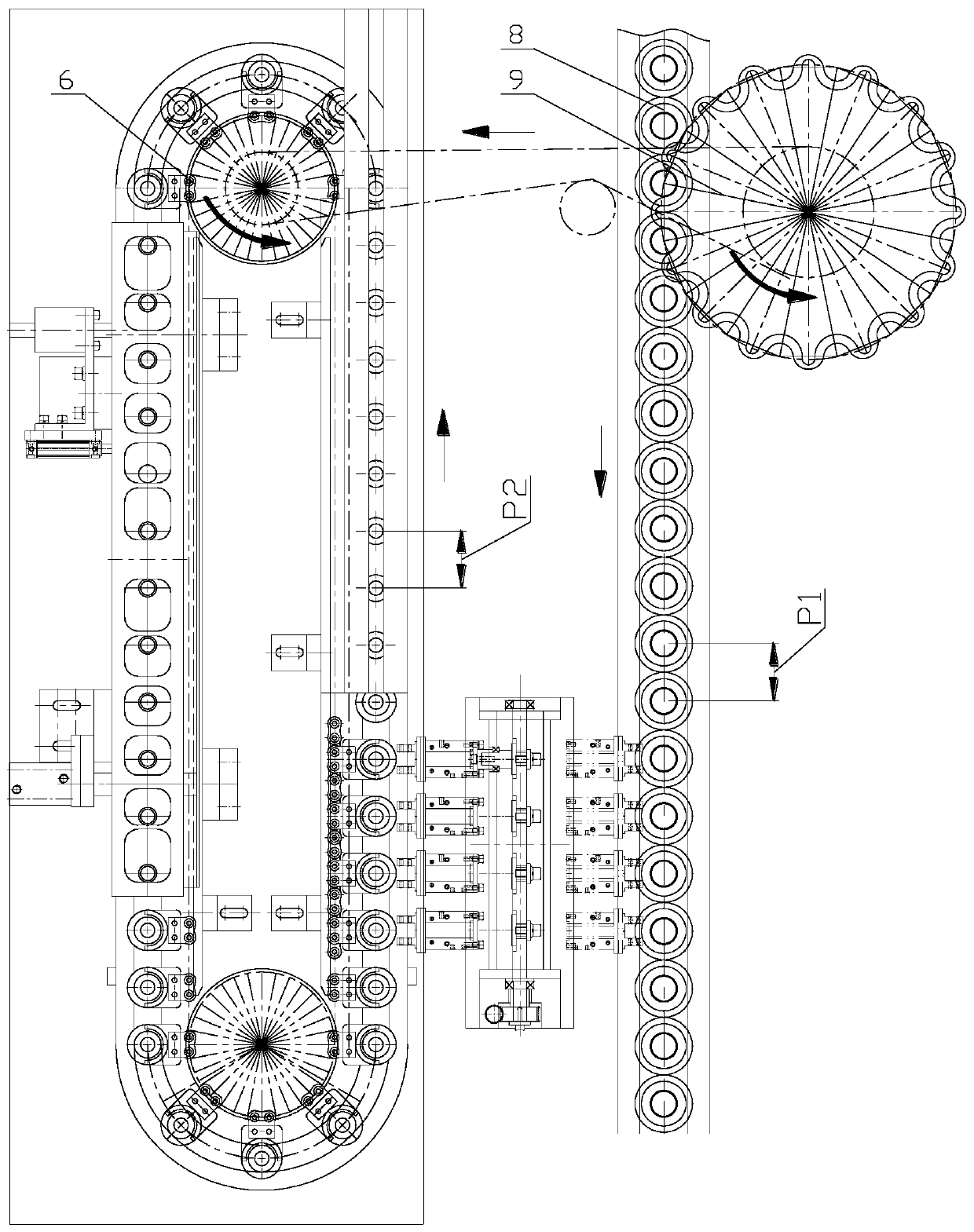

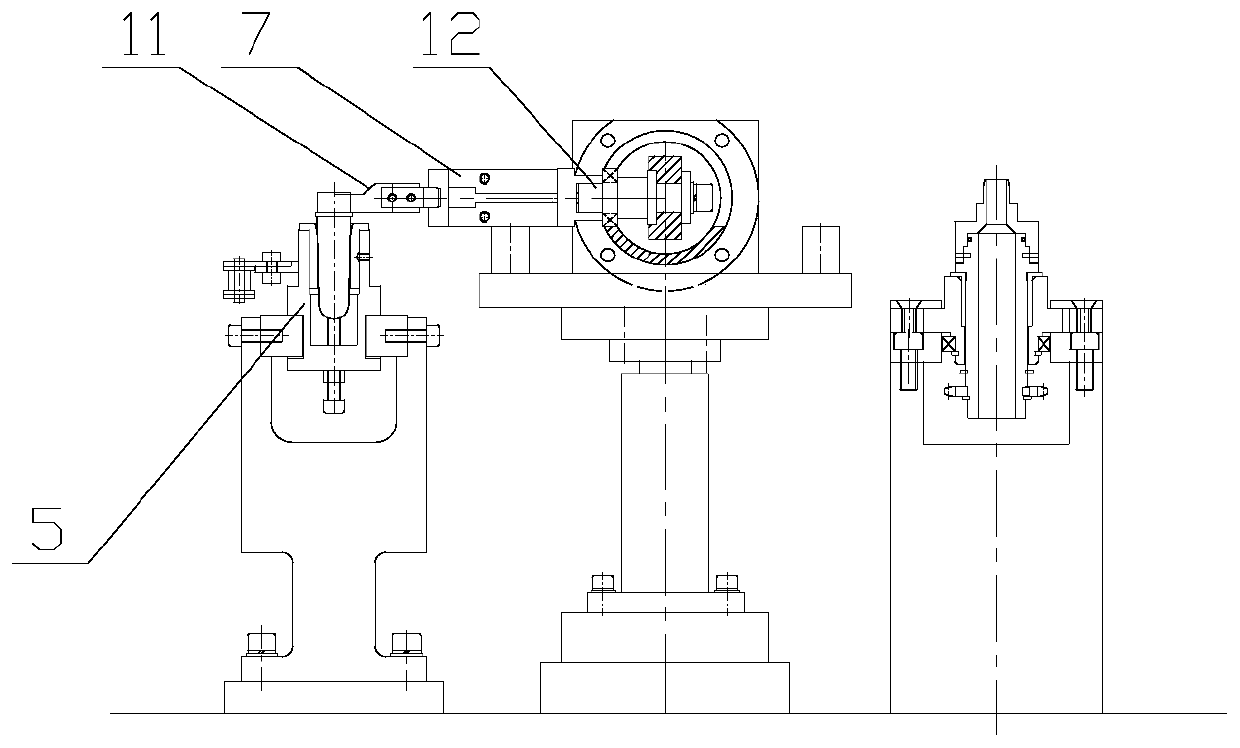

[0027] refer to figure 1 with figure 2 , a multi-level displacement transition mechanism, including a preform connecting device, a circular track and a flipping and shifting mechanism, the circular track is provided with equally spaced holes for placing preforms in the forward direction, and the preforms are connected The device is located above one side of the circular track, and the outer side of the other side of the circular track is provided with an overturning and shifting mechanism for turning the preform over and placing it upside down on the preform seat of the hollow molding machine. The mechanism includes an overturning platform, a displacement sleeve and a manipulator. The overturning platform is connected with a lifting assembly for raising or lowering the height of the platform. The displacement sleeve is fixed on the fixing seats on both sides of the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com