Visualization device and method for detecting sand carrying performance of CO2 fracturing fluid under high pressure dynamic filtration condition

A measurement device and fracturing fluid technology, applied in measurement devices, flow characteristics, indirect flow characteristics measurement, etc., can solve the problems of limited pressure resistance, influence of sand-carrying performance, and no consideration of sand-carrying fluid filtration, etc. The effect of strong safety, simple operation and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

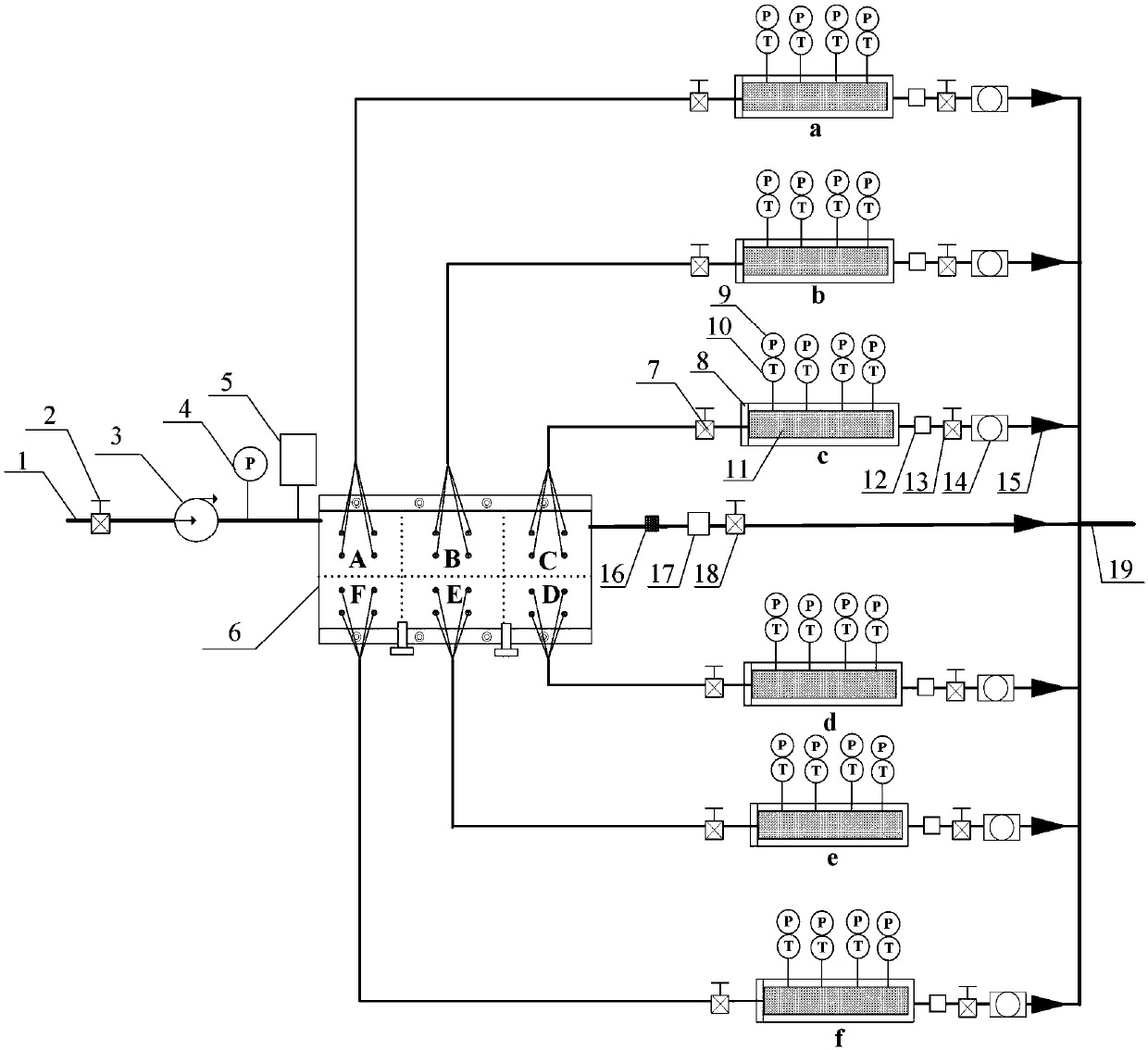

[0055] A measure of CO 2 A visualization device for sand-carrying performance under high-pressure dynamic fluid loss conditions of fracturing fluids, including a sand-carrying measurement device and an image acquisition device, characterized in that the visualization device also includes a fluid loss measurement device, and the visualization device is connected through a connecting pipeline, The fracturing fluid circulates in the connecting pipeline;

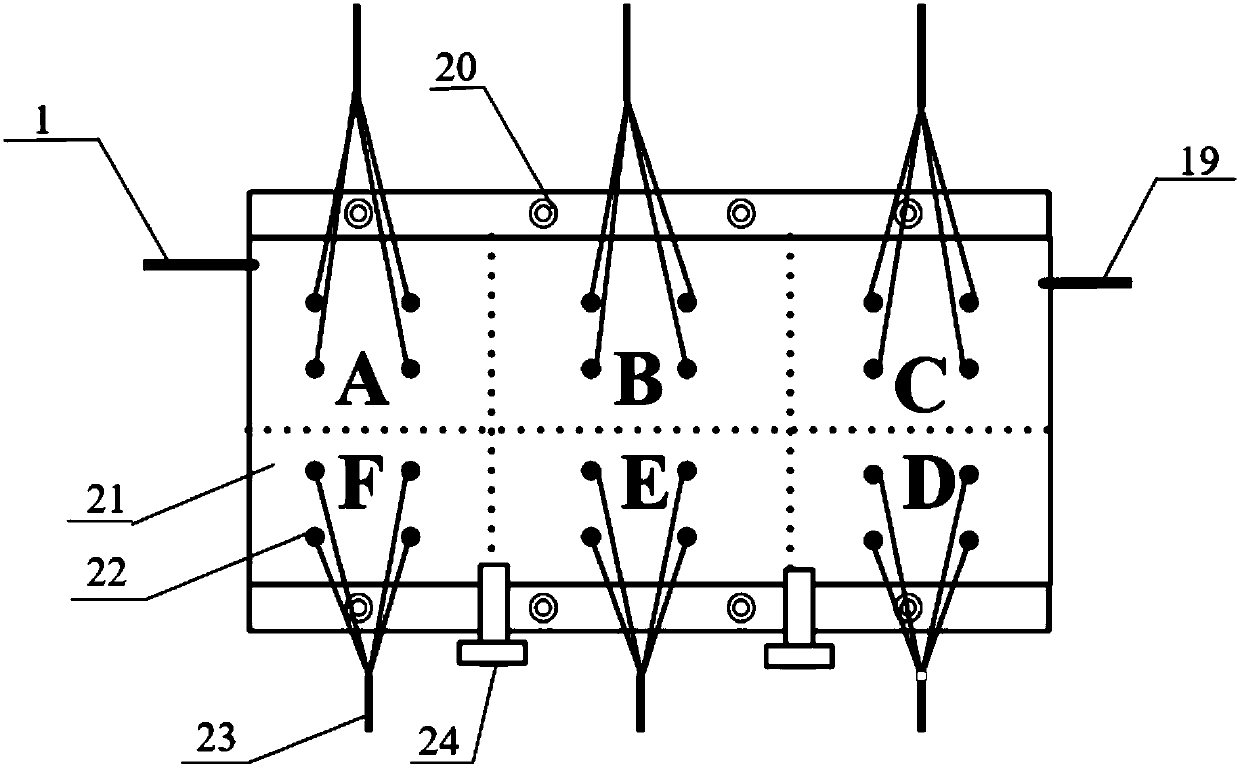

[0056] The sand-carrying measurement device includes a visual inner chamber 6 for simulating the sand-carrying flow process of the fracturing fluid in the fracturing fracture;

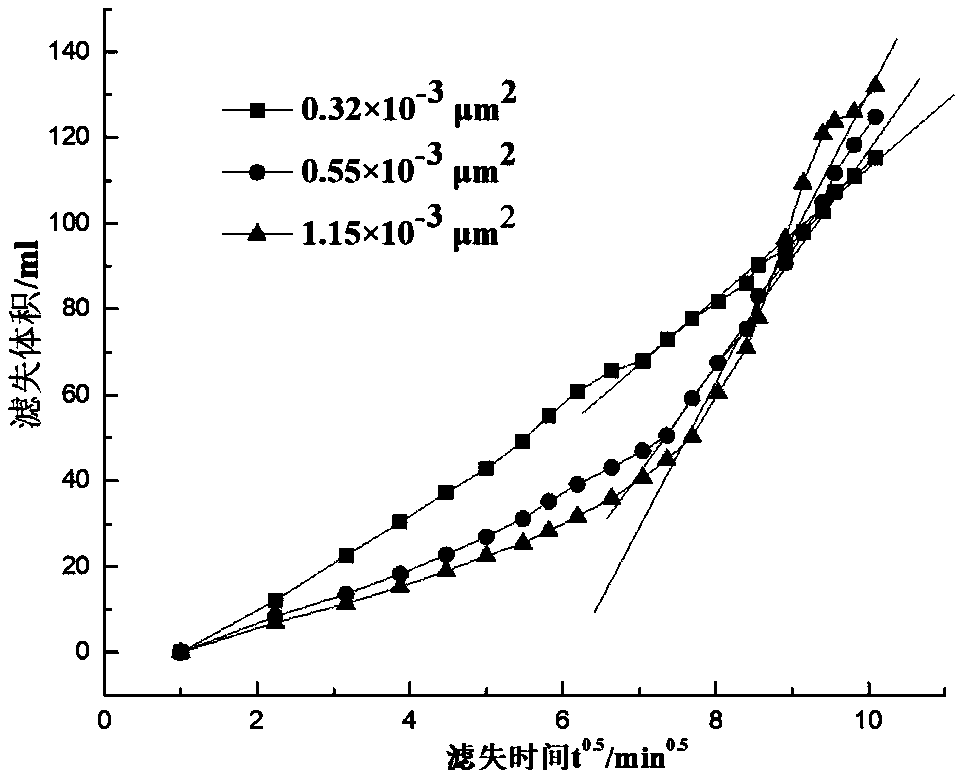

[0057] The fluid loss measurement device communicates with the visualized inner cavity 6, and the number of the fluid loss measurement devices is 6 groups, and each group of the fluid loss measurement devices includes a core holder 8 and a core 11, and the core 11 is set on In the core holder 8, the fluid loss measuring device is used for simulating the...

Embodiment 2

[0060] A measurement of CO as described in Example 1 2 A visualization device for sand-carrying performance under high-pressure dynamic fluid loss conditions of fracturing fluids. The difference is that the sand-carrying measurement device also includes a first valve 2, a circulation pump 3, a first The pressure sensor 4, the sand adding device 5, the second back pressure valve 17 and the fourth valve 18 arranged in sequence on the sand-carrying liquid discharge pipe 19, the described sand-carrying liquid injection pipe 1 and the described sand-carrying liquid discharge pipe 19 are respectively Connected to the front side wall and rear side wall of the visualization inner chamber 6;

[0061] Each group of the fluid loss measurement device includes a second valve 7, a core holder 8, a first back pressure valve 12, a third valve 13, and a mass flow meter 14 connected in sequence, and the core holder 8 is provided with 4 temperature sensors 10, pressure sensors 9;

[0062] The ...

Embodiment 3

[0064] A measurement of CO as described in Example 2 2 The visualization device for sand-carrying performance under the condition of high-pressure dynamic filtration of fracturing fluid, the difference is that a first filter screen 16 is set on the outlet end of the visualization inner chamber 6 on the sand-carrying fluid discharge pipe 19 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com