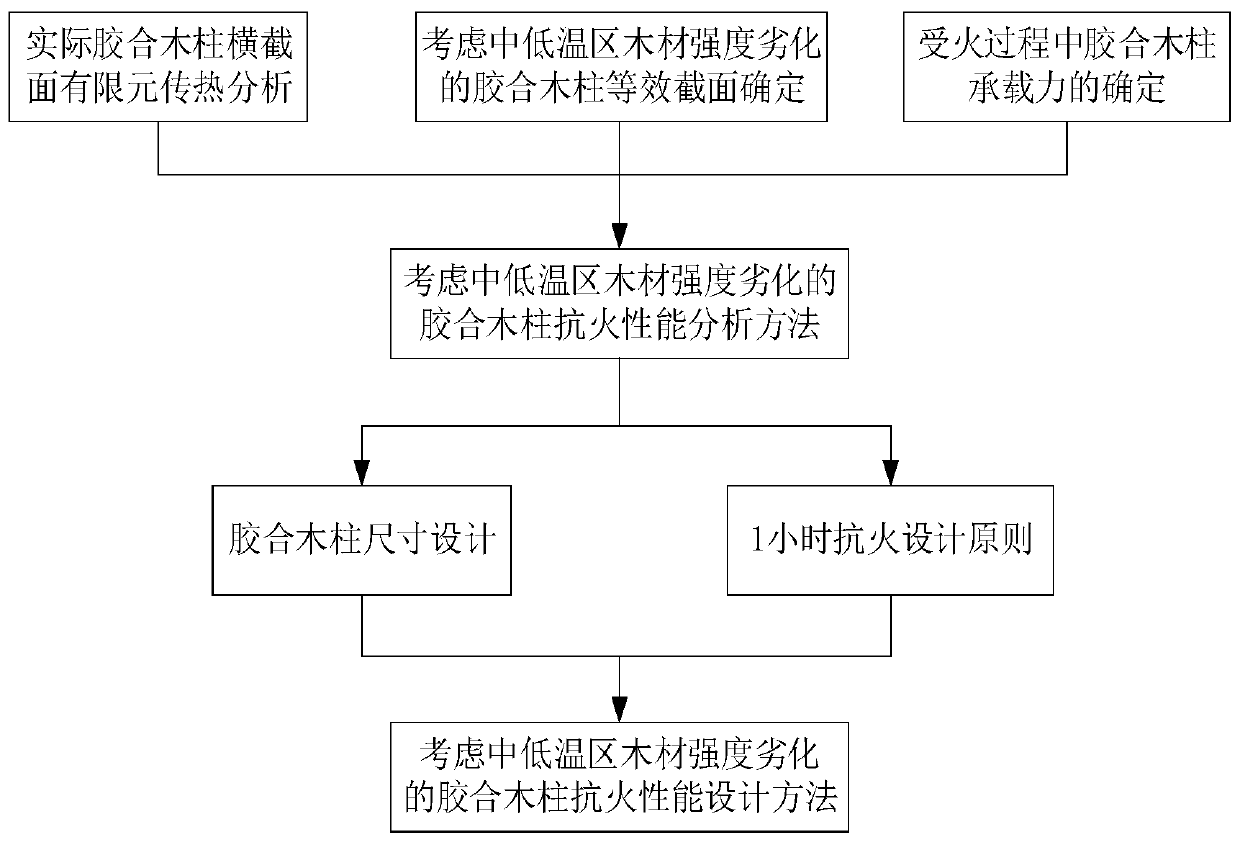

Fire resistance design method of glulam columns considering the degradation of wood strength in medium and low temperature regions

A technology of glulam columns and design methods, applied in calculation, instrumentation, geometric CAD, etc., can solve problems such as complex analysis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

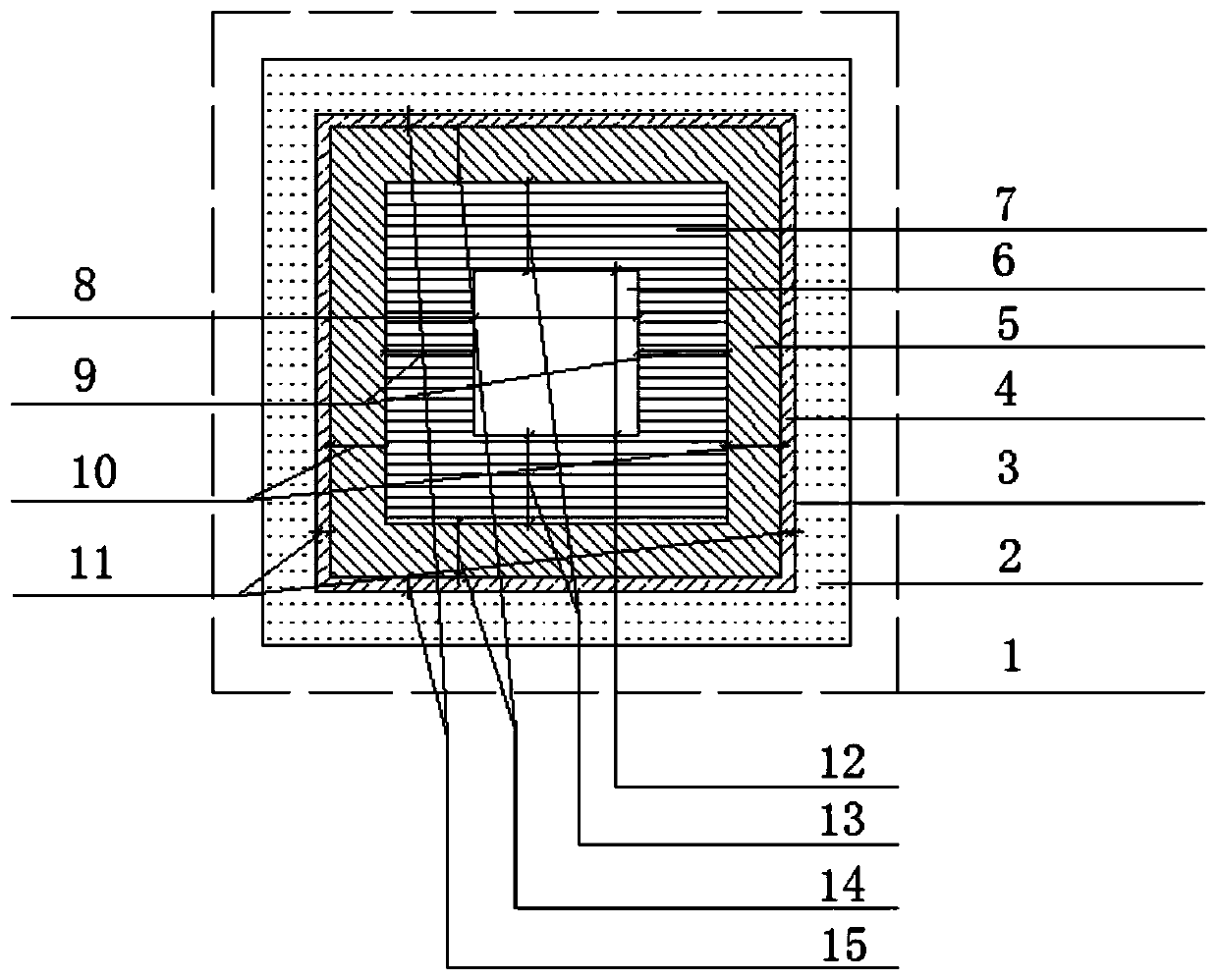

[0041] Douglas pine glued wood column, the compressive strength of Douglas pine wood along the grain at room temperature is 33.7MPa, and the density is 450kg / m 3 , the moisture content w is 15%, the size of the glulam column is length × width × height: 200mm × 200mm × 4000mm, the design load level is 20%, and it is subjected to fire on all sides.

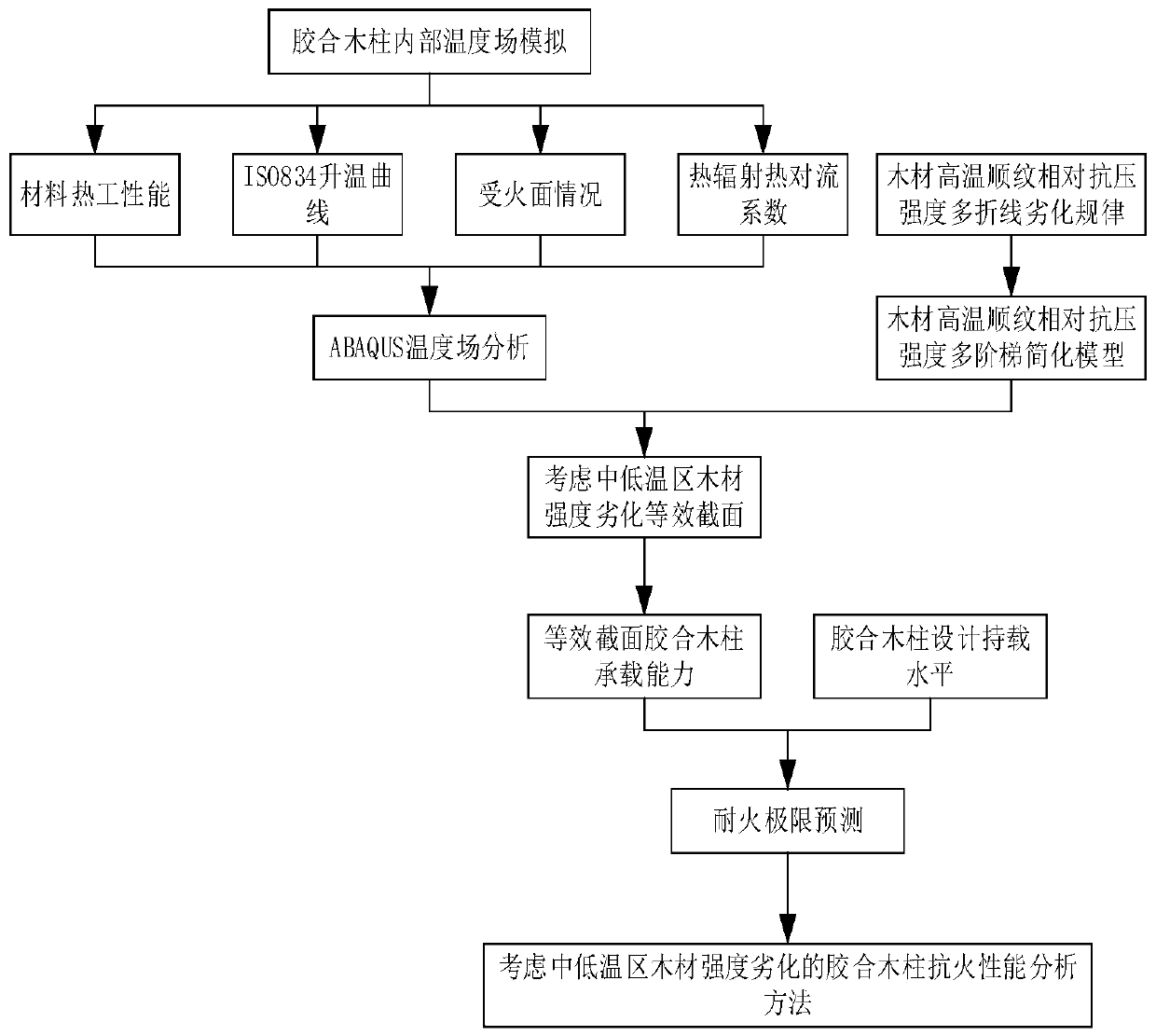

[0042] according to figure 1 and figure 2 To operate, the steps of its fire resistance design are as follows:

[0043] Step 1: According to the actual moisture content w of the glulam column is 15%, the density is 450kg / m 3 According to EN 1995-1-2, the material properties related to the establishment of wood thermal conductivity and specific heat thermal performance and density to dry density ratio are obtained, see Table 1 and Table 2. According to the actual fire situation of the four sides of the glued wood column, the radiation coefficient is set to 0.8 and the Stefan-Boltzmann constant is taken as 3.402×10 -6 . The heat...

Embodiment 2

[0061] Larch glued wood columns, the compressive strength along the grain of larch is 61.3MPa, and the density is 591kg / m 3 , the moisture content w is 11.0%, the size of the glulam column is length × width × height: 200mm × 200mm × 4000mm, the design load level is 65%, and it is subjected to fire on all sides.

[0062] The analyst's operation steps are the same as in Example 1:

[0063] Step 1: According to the actual moisture content w of the glulam column is 11.0%, the density is 591kg / m 3 . According to EN 1995-1-2, the material properties related to the establishment of wood thermal conductivity, specific heat thermal performance and density to dry density ratio are obtained, see Table 1 and Table 2. According to the actual fire situation of the four sides of the glued wood column, the radiation coefficient is set to 0.8 and the Stefan-Boltzmann constant is taken as 3.402×10 -6 . The heat exchange of the surface of the glulam column exposed to fire is set to a heat di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com