Bamboo curtain-concrete prefabricated component panels and prefabricated components and their optimal size determination method

A technology of prefabricated components and concrete, which is applied to pavements, roads, pavements and other directions paved with prefabricated blocks, which can solve the problems of the application of concrete prefabricated parts, achieve convenient construction, good tensile properties along the grain, and reduce manufacturing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The bamboo strip curtain-concrete prefabricated component of the present invention will be further described below in conjunction with the embodiments and accompanying drawings.

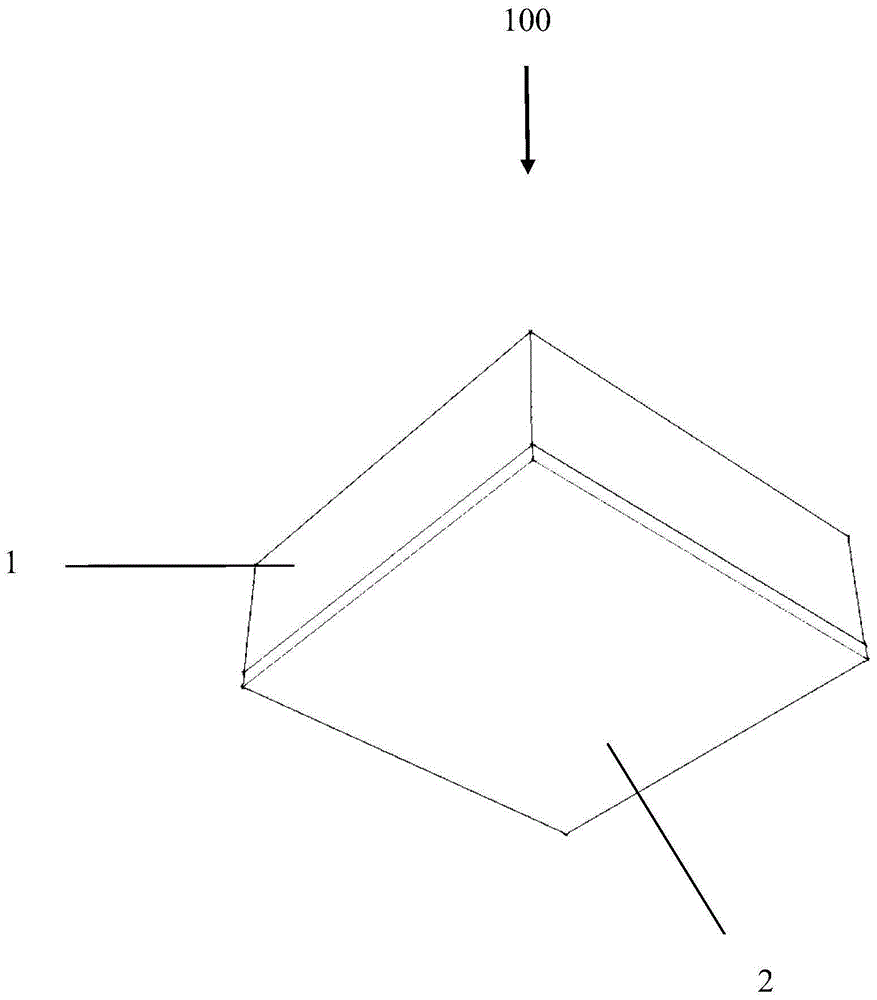

[0049] figure 1 It is a schematic diagram of the bamboo strip curtain-concrete prefabricated component provided in this embodiment.

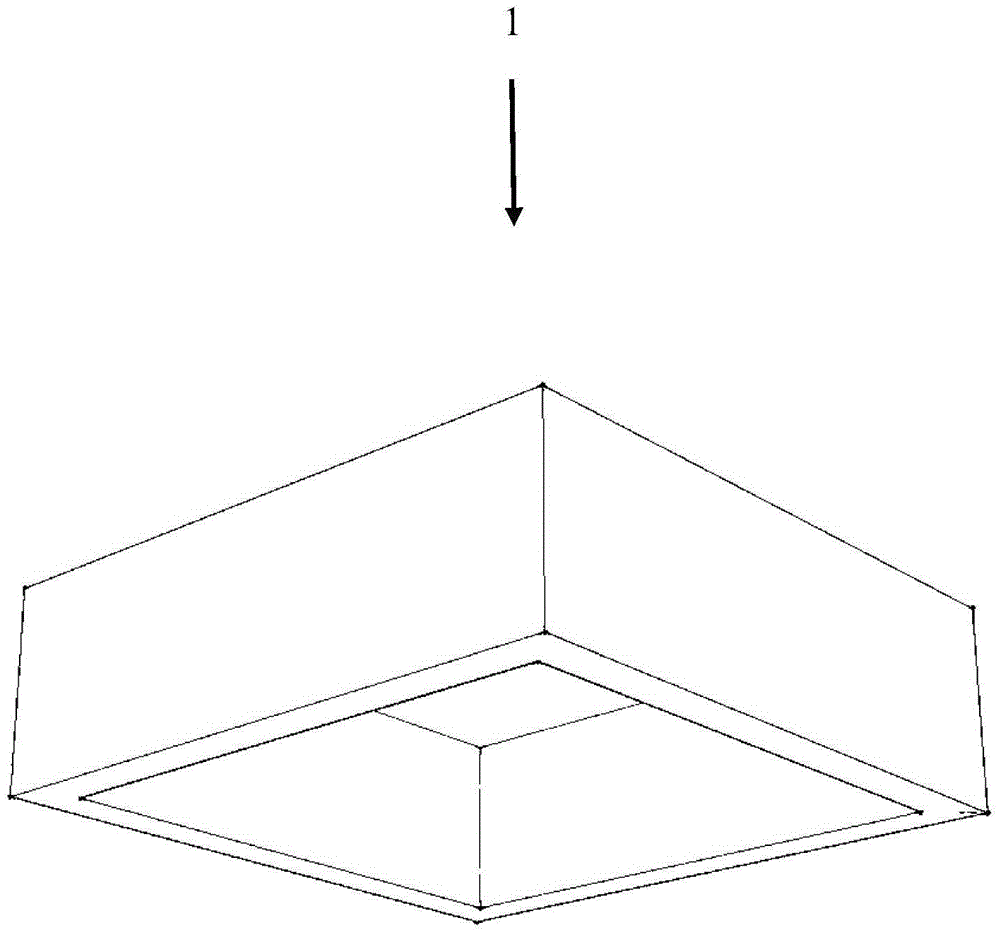

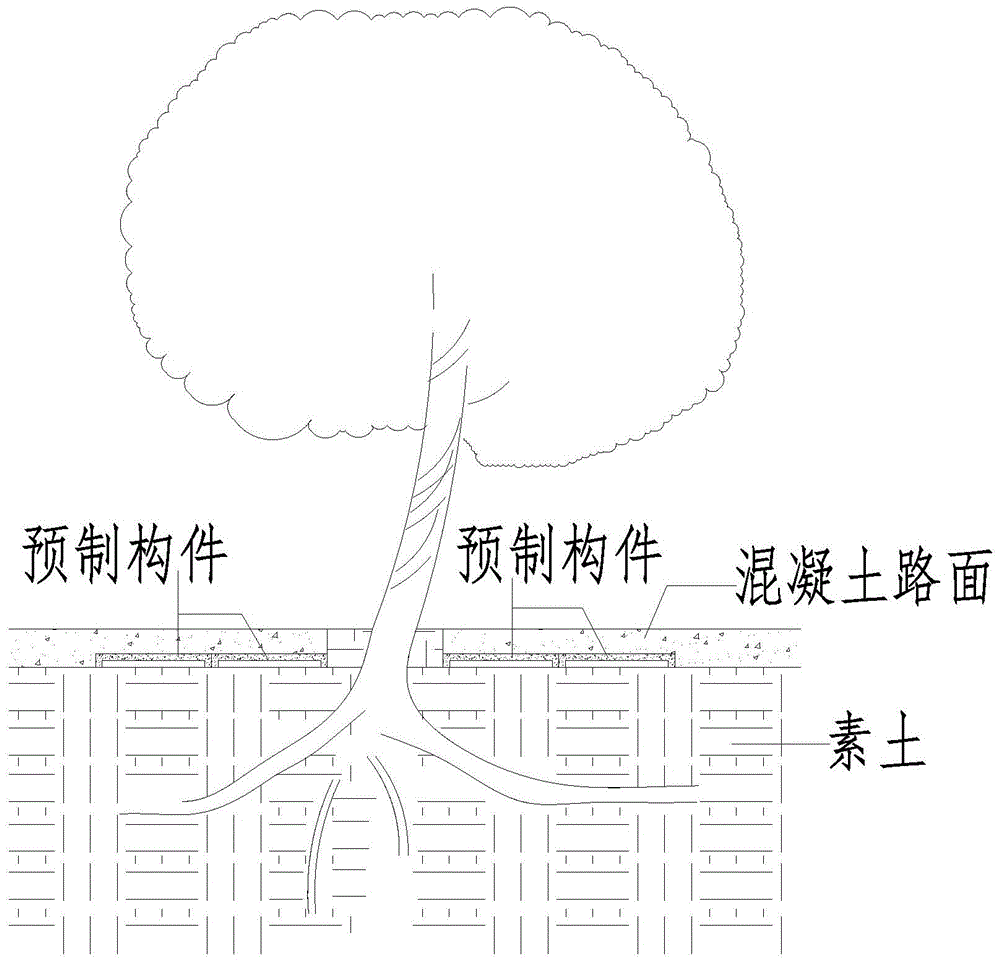

[0050] Such as figure 1 As shown, the bamboo strip curtain-concrete prefabricated component 100 in this embodiment includes a concrete prefabricated component 1 and a bamboo strip curtain layer 2 . The concrete prefabricated component 1 is in the shape of a basket with the bottom facing upwards, and is in contact with the concrete pavement, and is used to bear the load of the upper concrete pavement. Bamboo curtain layer 2, in contact with plain soil, is used to buffer the extrusion of the road surface caused by the growth of tree roots. In this embodiment, the planar dimensions of the bamboo strip curtain layer 2 and the concrete prefabricated component 1 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com