Cam grooving machine

A cam, cam surface technology, used in groove needles, mechanical equipment, engine components, etc., can solve problems such as low production rate and complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

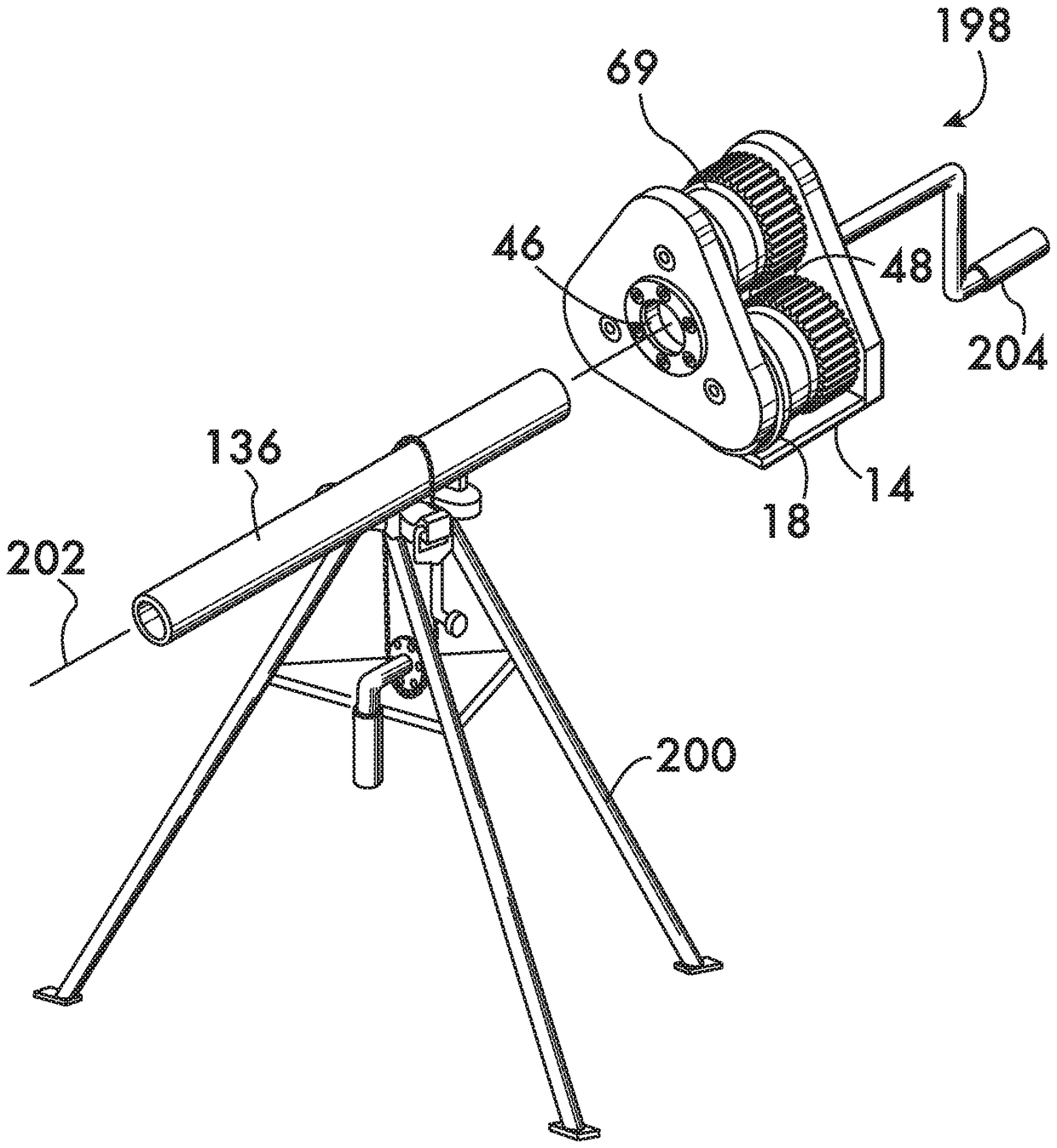

[0042] figure 1 An exemplary apparatus 10 is shown for cold working a tubular element, such as forming a circumferential groove in the outer surface of the tubular element. Device 10 is shown pivotally mounted on a rotary power chuck 12 . Such chucks are well known, an example being the Ridgid 300 powered driver sold by Ridgid of Elyria, Ohio.

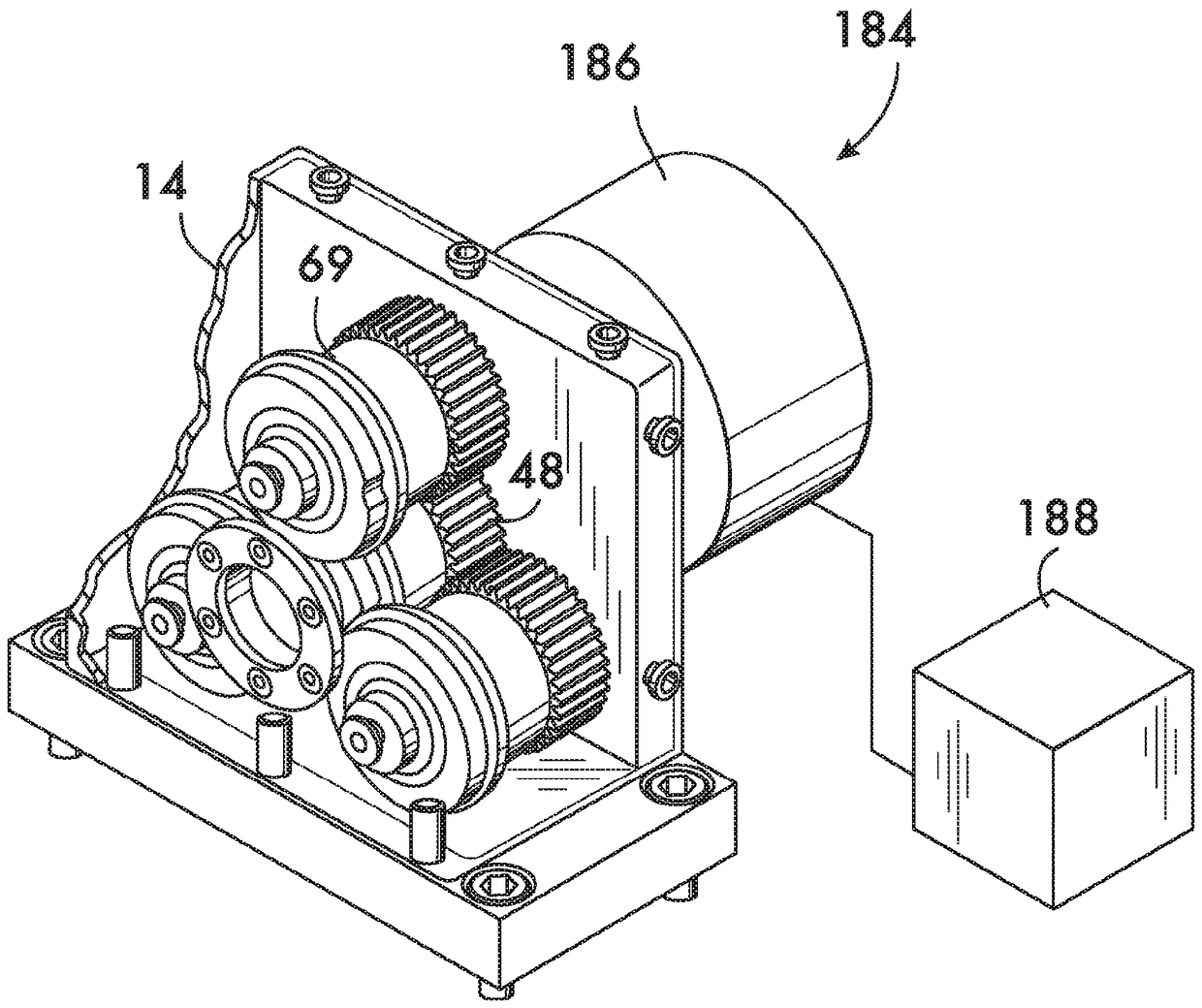

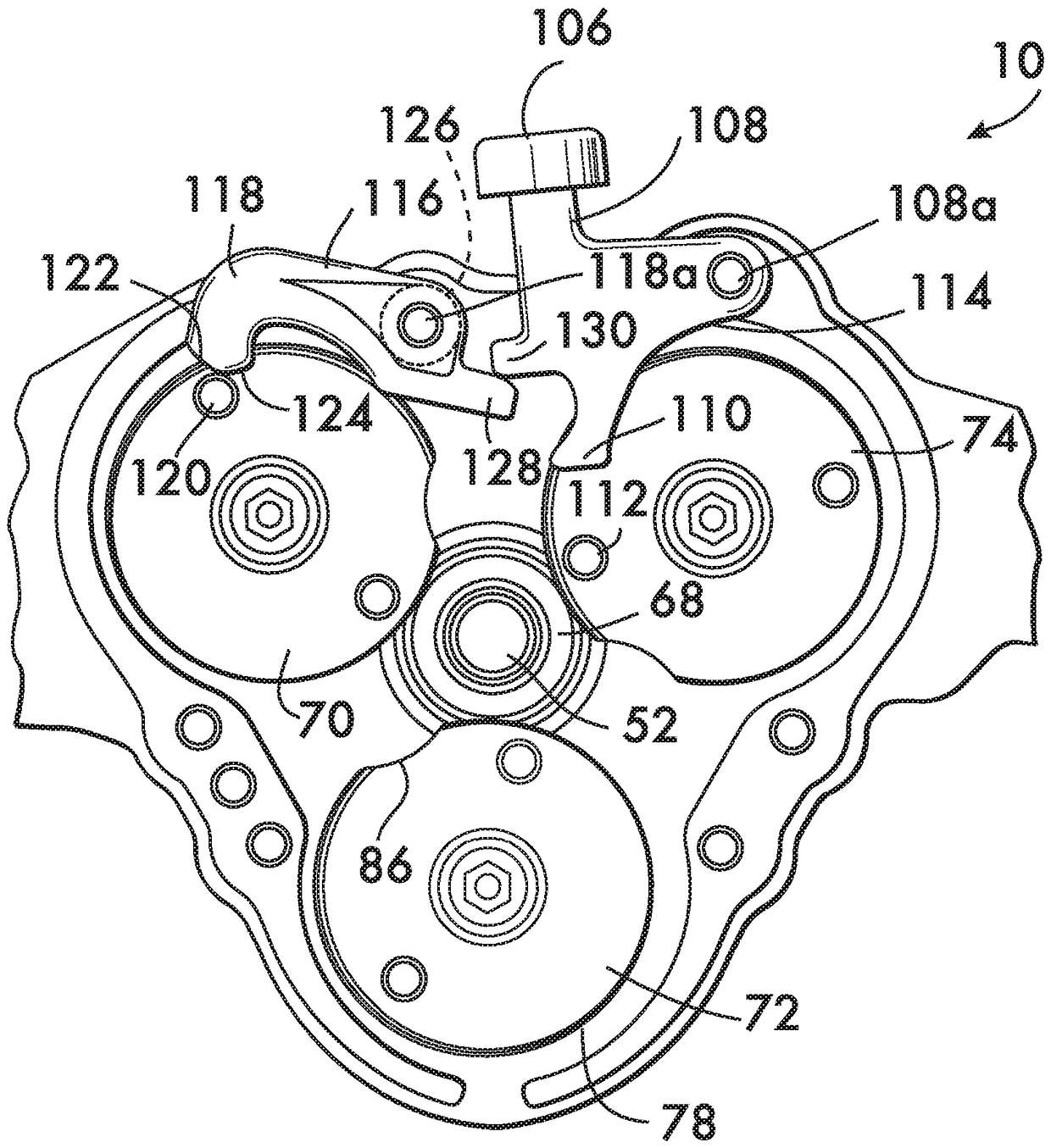

[0043] figure 2 An exploded view of device 10 including housing 14 is shown. The housing 14 is formed of a housing body 16 and a cover 18 . A plurality of gears (in this example three gears 20, 22 and 24) are rotatably mounted on respective shafts 26, 28 and 30 which are supported by housing body 16 and cover 18 and define respective Axes of rotation 32 , 34 and 36 . The axes 32, 34 and 36 are arranged parallel to each other. In one practical design, each gear 20 , 22 and 24 has a corresponding flanged bush 38 and may also have a thrust washer 40 and a compression spring 42 . A compression spring 42 acts between the gears 20, 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com