Elastic grinding block

A grinding block and elastic technology, applied in grinding/polishing equipment, grinding/polishing hand tools, metal processing equipment, etc., can solve problems such as increasing the cost of use, achieve great economic significance, reduce the cost of use, installation and replacement handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

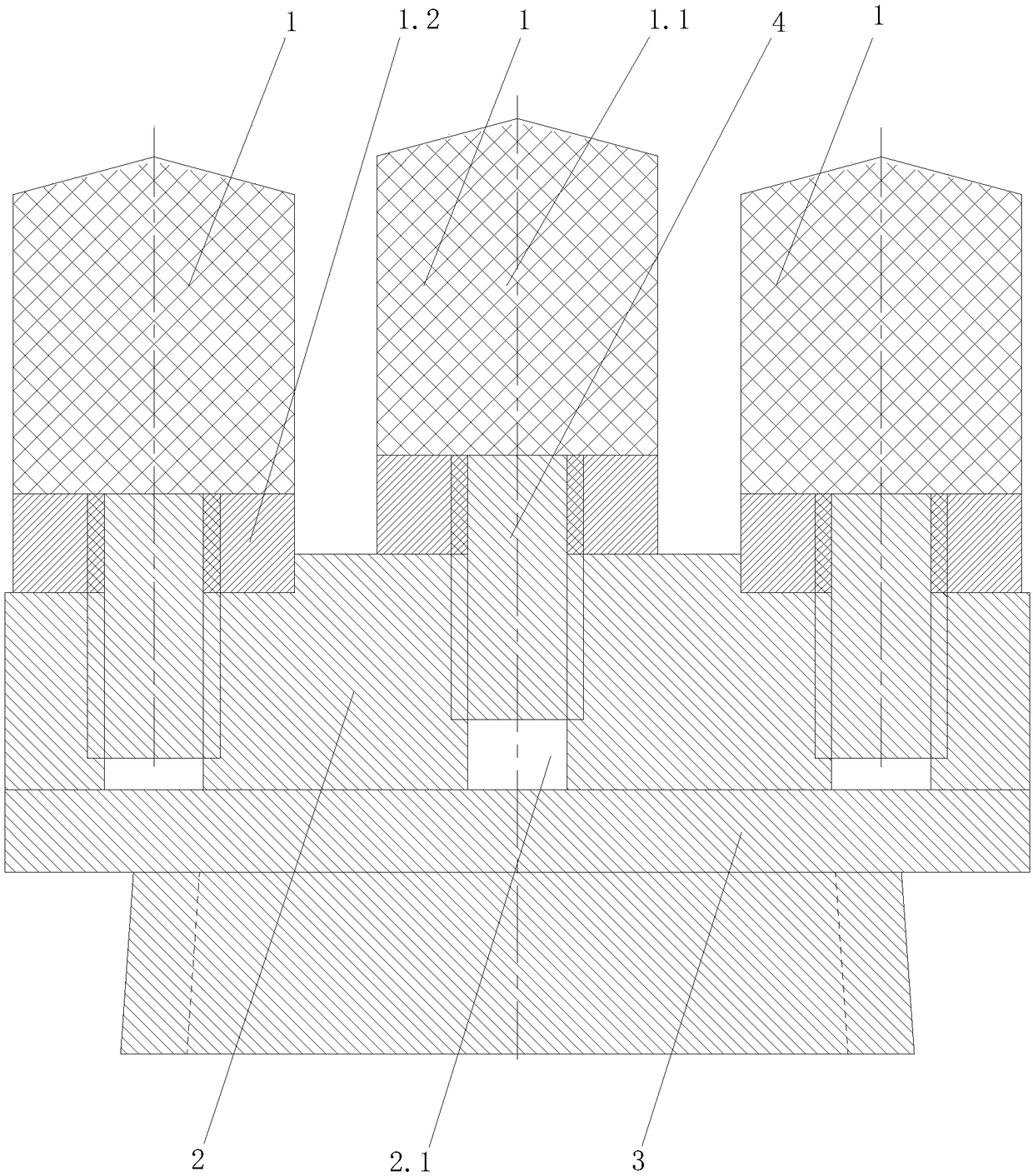

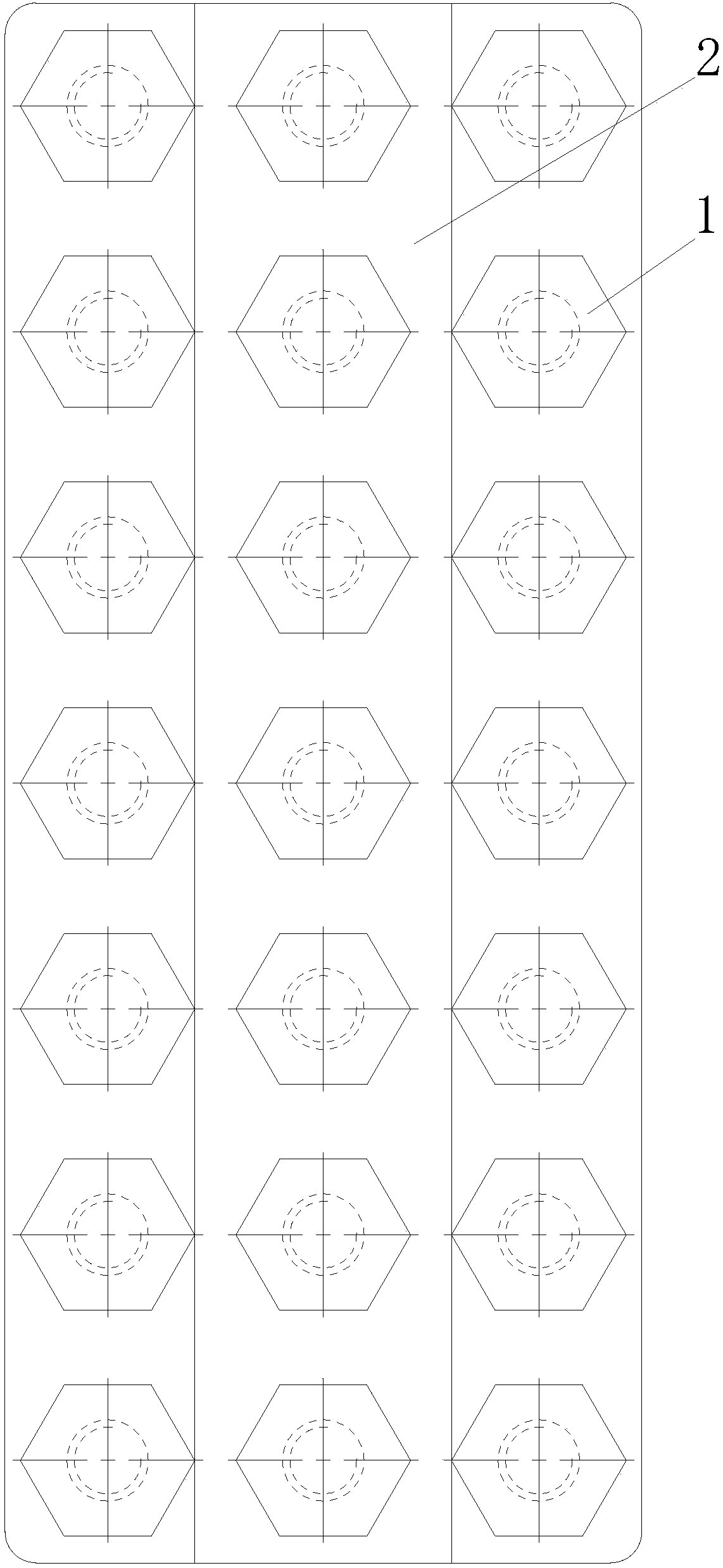

[0023] Such as figure 1 , figure 2 As shown, the present invention includes a grinding head 1, an elastic body 2, a base 3 and a screw 4. The grinding head 1 includes a working layer 1.1 and a transition layer 1.2 fixedly connected with the working layer 1.1. The elastic body 2 and the base 3 are fixedly connected into one body, and the elastic body 2 is provided with a plurality of holes 2.1 adapted to the screw rod 4 . One end of each screw 4 and a transition layer 1.2 on a grinding head 1 are first screwed together and then sintered and fixed together, and the other end of each screw 4 is screwed together with a hole 2.1 provided on the elastic body 2 . The main body of the grinding head 1 is polygonal, and the uppermost part of the working layer 1.1 is a polygonal pyramid. The main body of the grinding head 1 in this embodiment is preferably a hexagonal prism, and the uppermost part of the working layer 1.1 is a hexagonal pyramid. In addition, the elastic body 2 is a ...

Embodiment 2

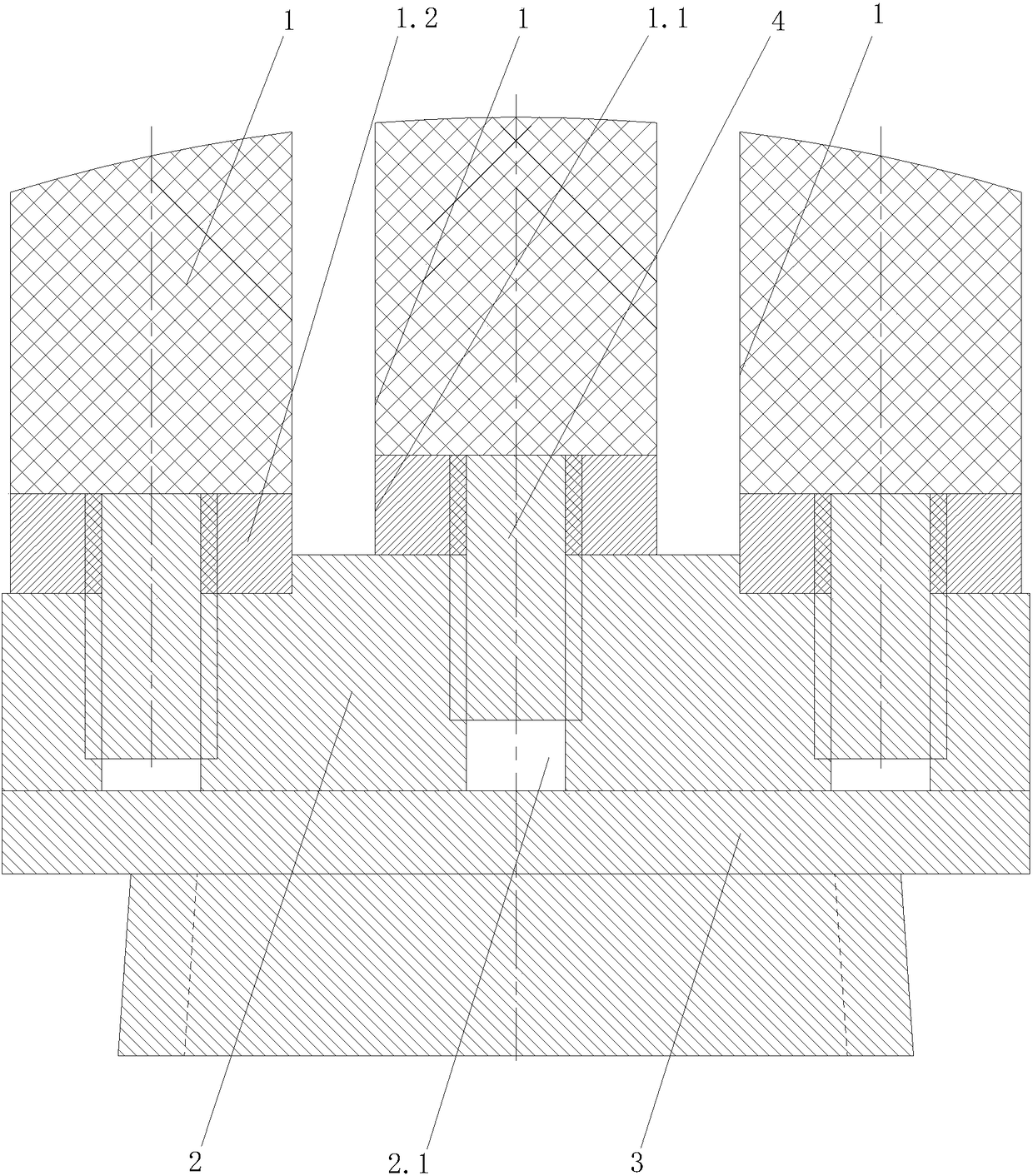

[0025] Such as image 3 As shown, the difference between the second embodiment and the first embodiment is that the working faces of the working layers 1.1 of the grinding heads of each column in the second embodiment are on the same cylindrical surface, and the axisymmetric plane of the cylindrical surface is connected to the elastic body 2. The distance between the left and right sides is equal. In addition, in this embodiment, the connecting rod 4 is a polished rod, and the connecting rod 4 and the hole 2.1 are glued and fixed together. After the old grinding head is worn out, as long as the fixing glue is melted by heating, the old grinding head can be removed and replaced. The new grinding head enables the base to be used again, thereby greatly reducing the cost of processing, manufacturing and use, and has great economic benefits.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com