Manufacturing method of wallpaper embossing roller

A production method and technology of embossing rollers, applied in the direction of mechanical processing/deformation, can solve the problem of single pattern of wallpaper, and achieve the effects of low cost, shortened production cycle, and large variability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

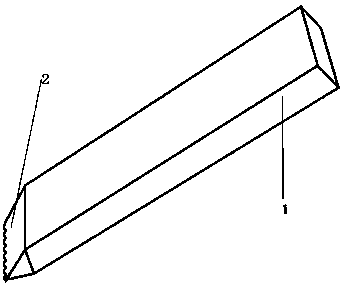

Image

Examples

Embodiment Construction

[0022] A method for making a wallpaper embossing roller, comprising the steps of:

[0023] S1, 3D scanning to obtain cloth and leather textures;

[0024] S2, select the pattern, the pattern comes from a web page, mobile phone photo or computer drawing, and add the texture obtained in S1 to the selected pattern;

[0025] S3, adding flower-shaped edge stitches to the image acquired by S2;

[0026] S4, using the three-dimensional automatic measurement software to extract and split the three-dimensional layers of the image processed in S3, and formulate the engraving depth of each layer;

[0027] S5, select and make the roll body, apply black glue on the surface of the selected roll body, the thickness of the glue is 0.05mm;

[0028] S6, performing laser engraving on the roller body processed in S5 according to the engraving depth of each layer formulated in S4;

[0029] S7, using ferric chloride solution to corrode the engraved area of S6;

[0030] S8, hand-carved flower-sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com