Patents

Literature

138results about How to "Highly variable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

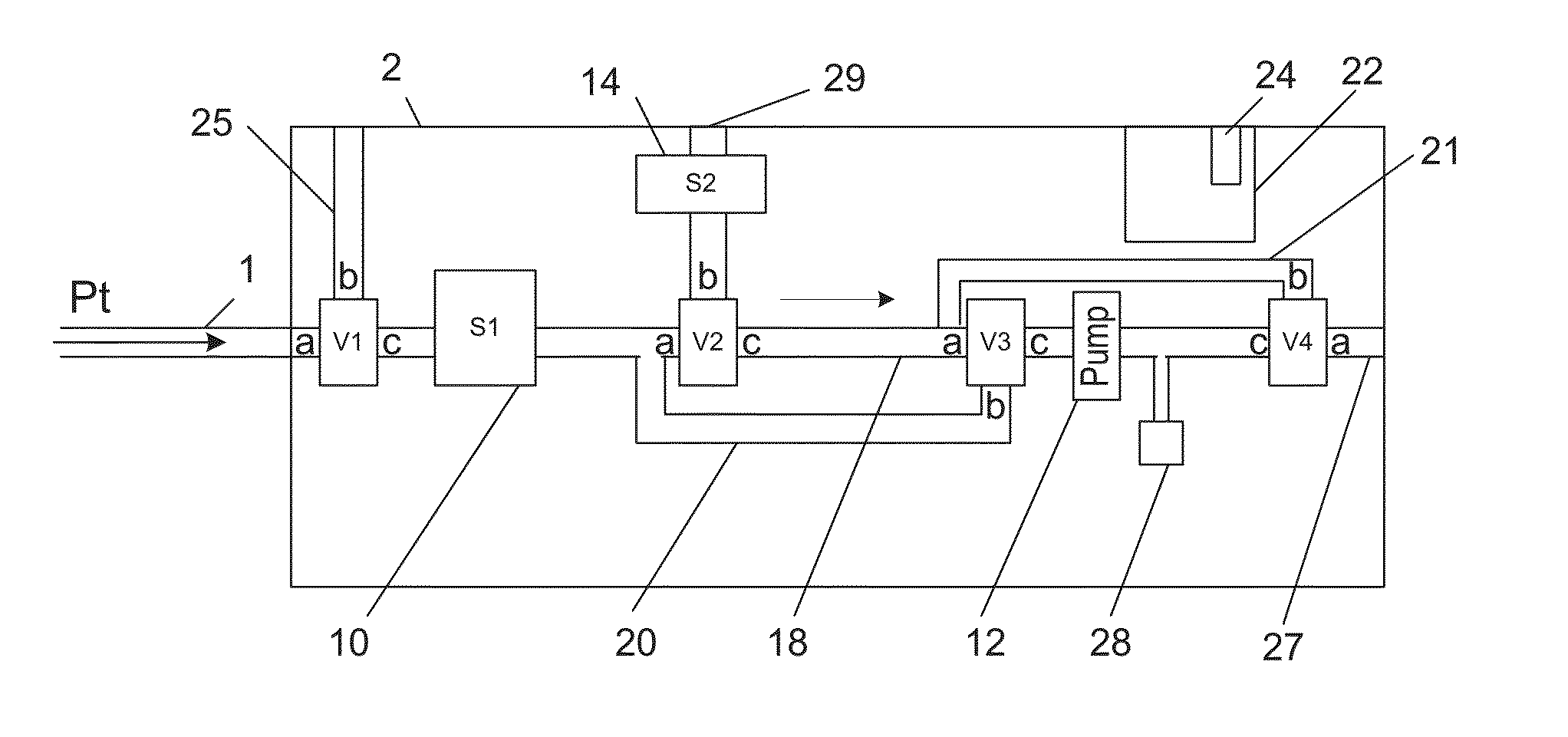

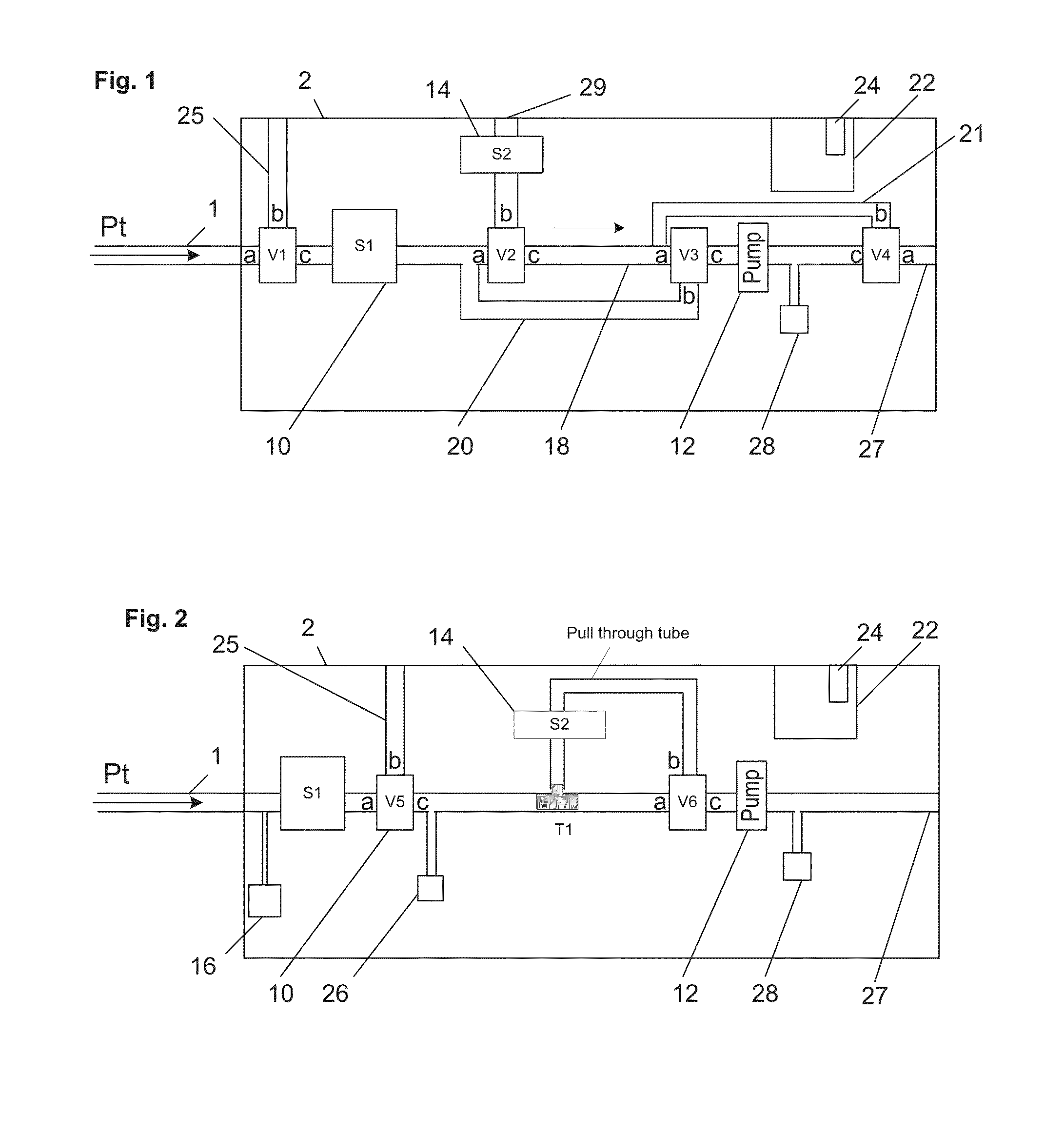

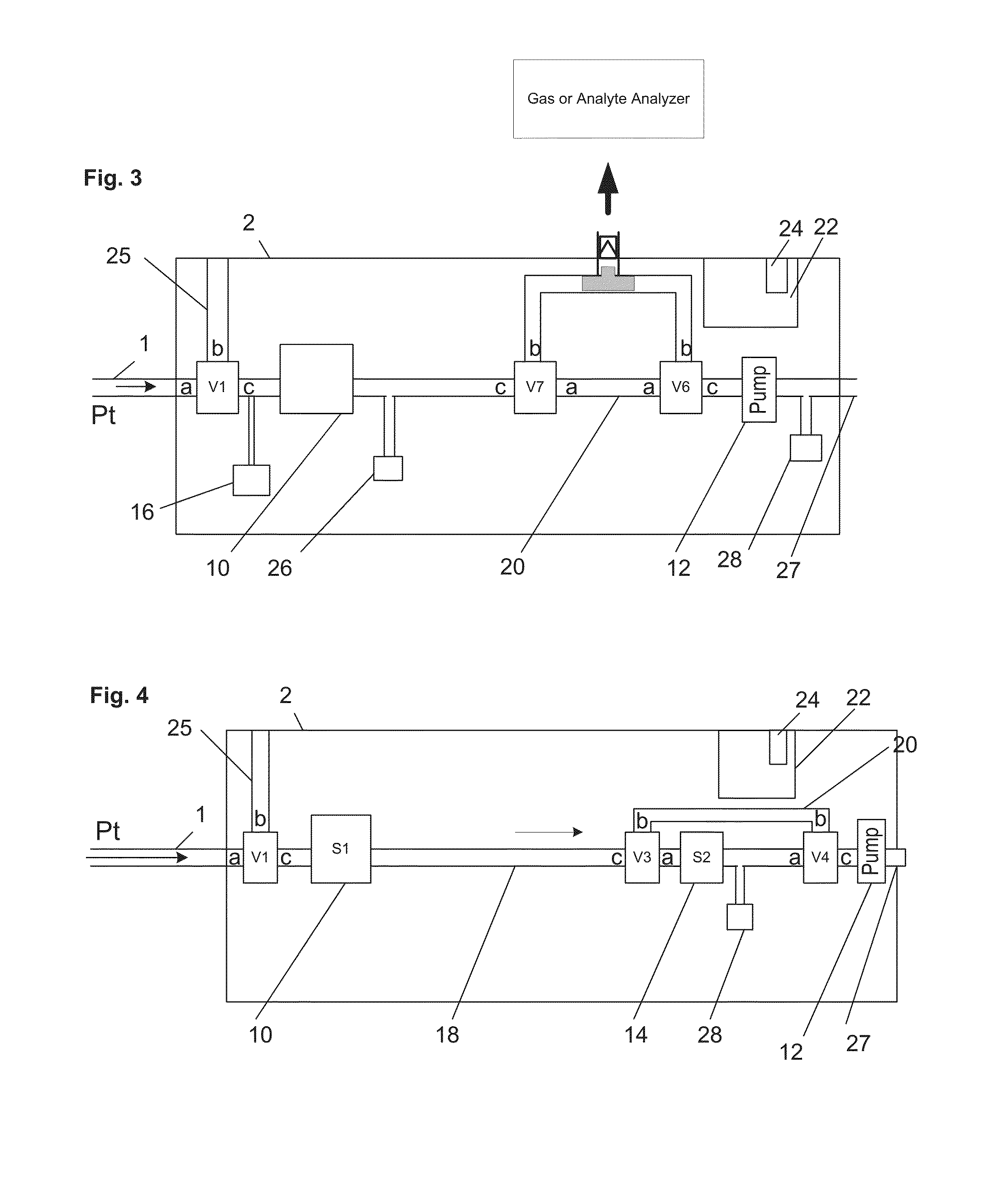

Selection, segmentation and analysis of exhaled breath for airway disorders assessment

InactiveUS20150265184A1Increase sensitivityGood sensitivityUser/patient communication for diagnosticsRespiratory organ evaluationAssessment methodsAsthma

Methods and systems are described to automatically obtain and analyze a lung airway gas sample from the breath of a person for compositional analysis. These techniques may provide an improved method for example for accurately and reliably measuring nitric oxide for asthma assessment in young children and non-cognizant patients.

Owner:CAPNIA INC

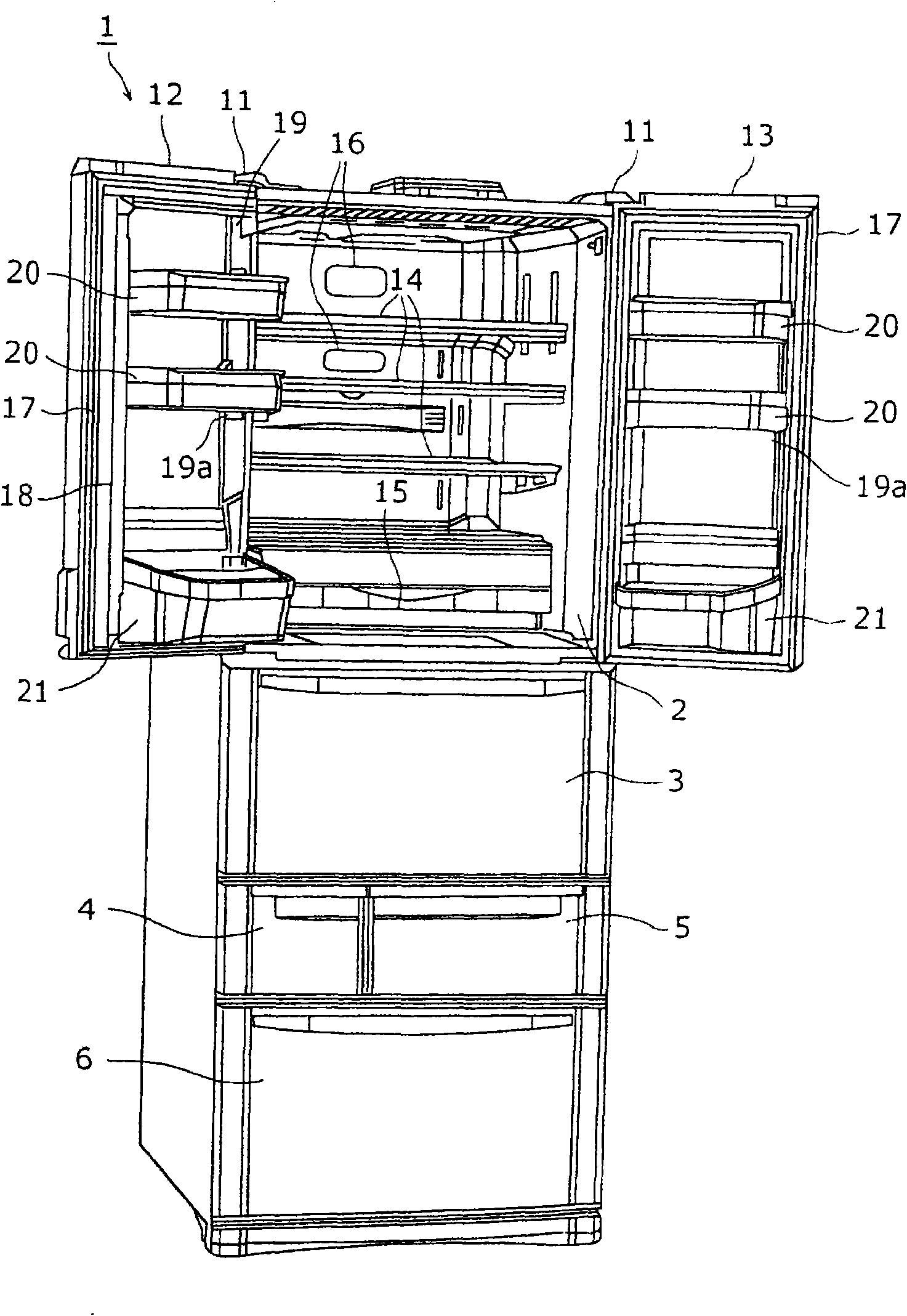

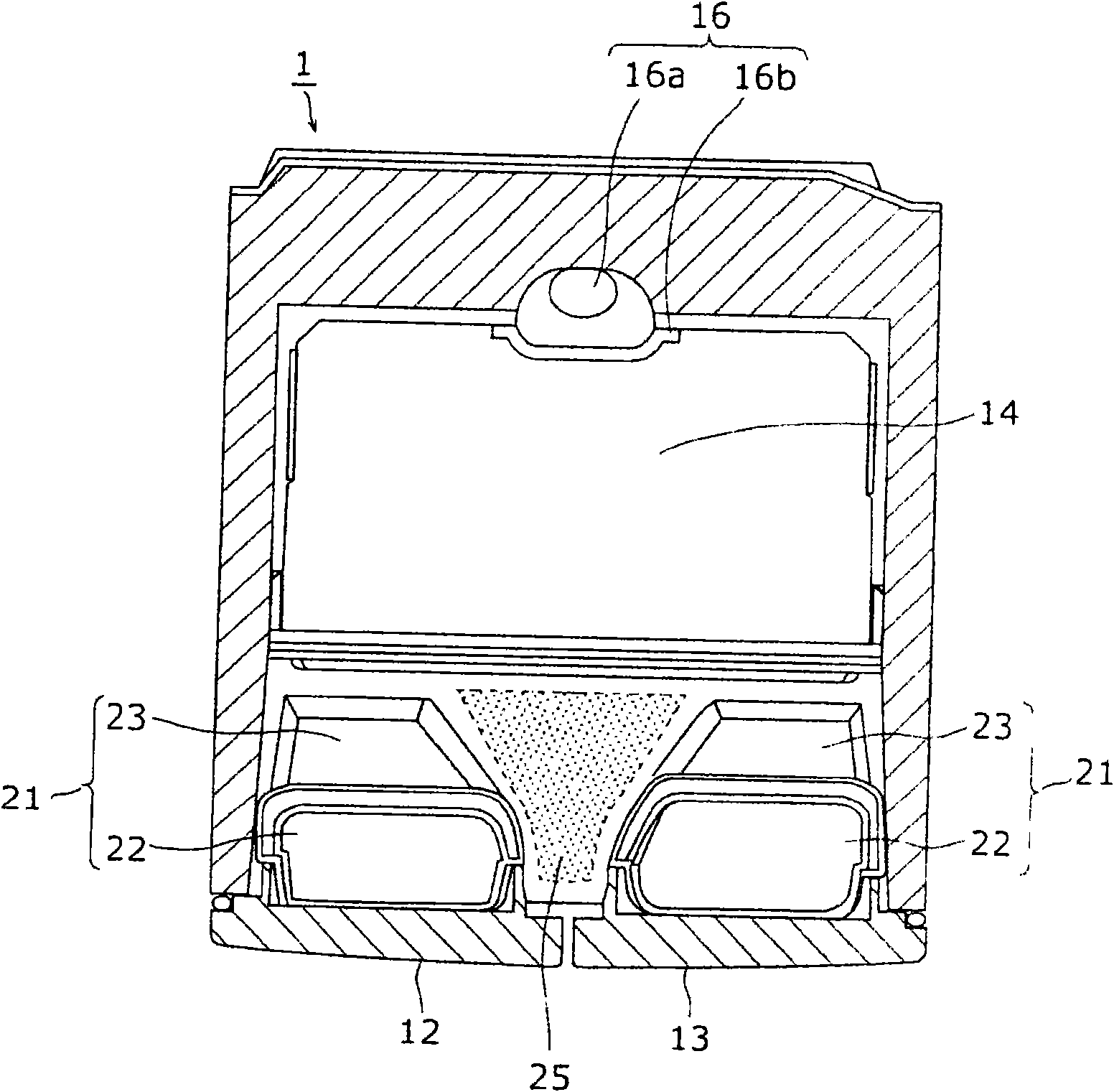

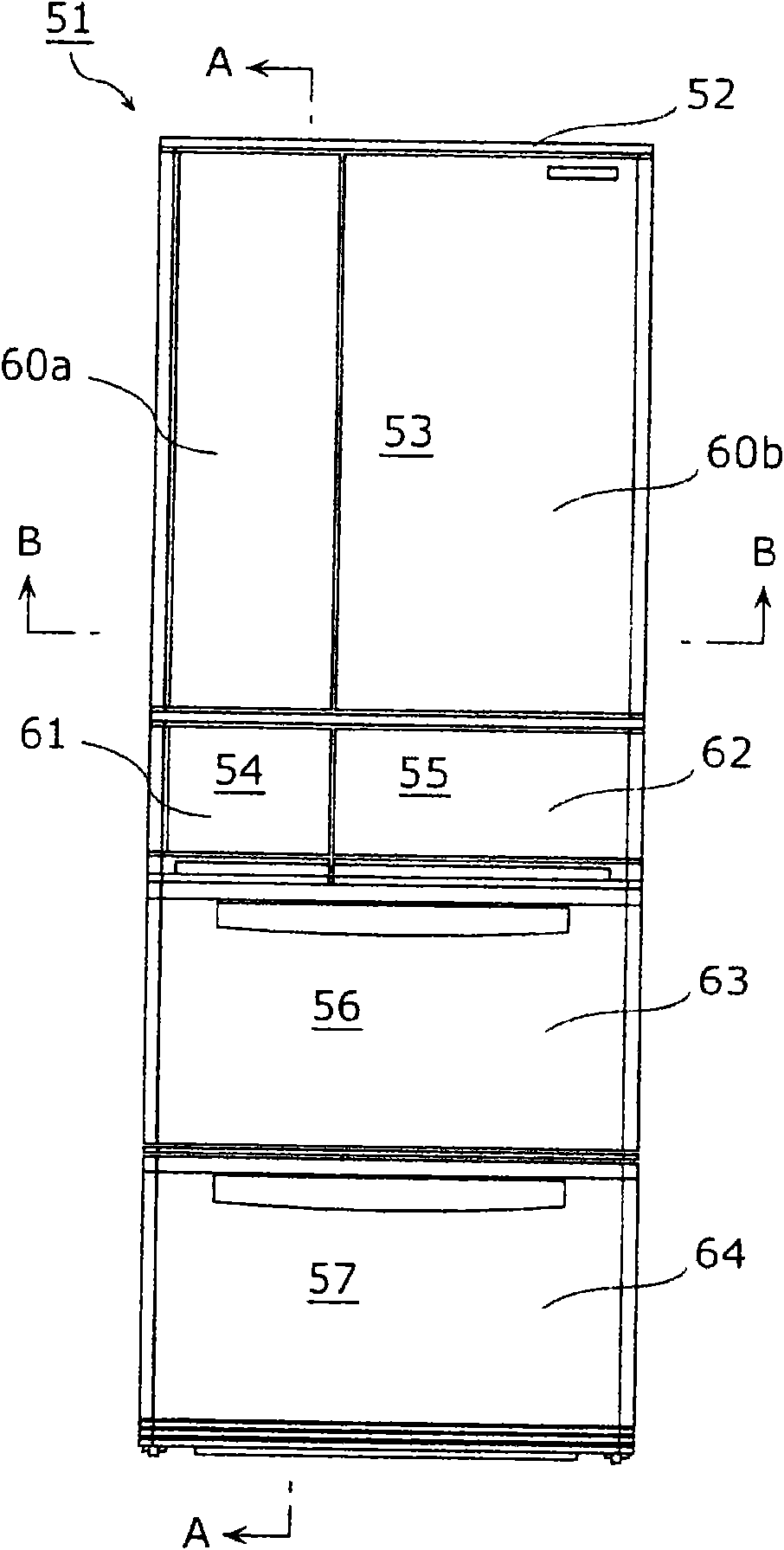

Refrigerator

InactiveCN101611281AImprove convenienceEffectively differentiate storageLighting and heating apparatusLighting arrangementRefrigerator carEngineering

To provide a refrigerator that has excellent storage efficiency and convenience. The refrigerator (51) includes a refrigerator compartment (53) having an opening in a front plane, in which items are stored, and a shelf plate (80) disposed to span between the left side-surface and the right side-surface of the refrigerator compartment (53) in a bridging manner, and having different horizontal depths on the left and right. With this, the inoperative space present in the refrigerator compartment (53) can be filled up by a horizontally deep portion of the shelf plate (80), and the two storage areas of the shelf plate (80), that is, the horizontally deep area and the horizontally shallow area can be used separately.

Owner:PANASONIC CORP

Environmental protection remover

InactiveCN101126052AAccelerated disengagementImprove decomposition abilityAnionic-cationic-non-ionic surface-active compoundsDetergent compounding agentsSorbitanFatty alcohol

The invention relates to an environment-friendly ablution used in washing, sterilizing and removing smell to protect clothing, plastic, rubber, office articles, household appliances, auto-inner ornament and toilet in daily life. In order to solve the problems in the prior art, biosurfactant, promoter enzyme, etc. are adopted to be remixed with relative organic reagent. The invention comprises n-acyl glutamate, pineapple enzymic, dodecyl dimethyl benzyl ammonium bromide, fatty alcohol polyoxyethylene ether, ester succinate sulfonate, boric acid diglyceride, linear alkyl benzene sulphonate, sorbitan fatty acid, fatty acid diethanol amide, sunscreen, carbamide, sodium hypochlorite, odor component water. The invention has six functions of 1.laundry washing, decontaminating, sterilizing; 2.plastic and rubber cleaning; 3.office articles and hoursehold appliances renewing; 4.sleeping mat cleaning, decontaminating, sterilizing and acarus killing;5.auto-inner ornament cleaning, sterilizing and smell removing; 4 toilet cleaning, sterilizing, mildew and abnormal smell removing; 6.wall cleaning and stain removing as well as innocuity, no pollution and environment protective.

Owner:王锦容

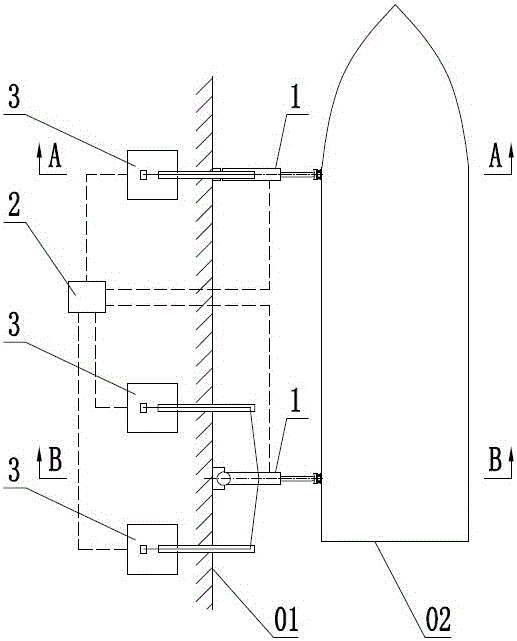

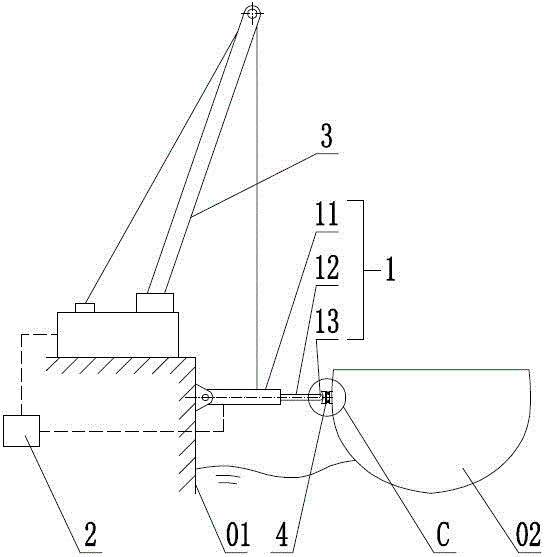

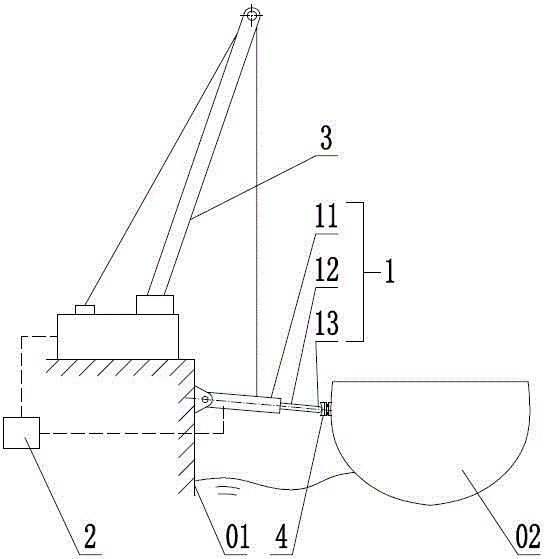

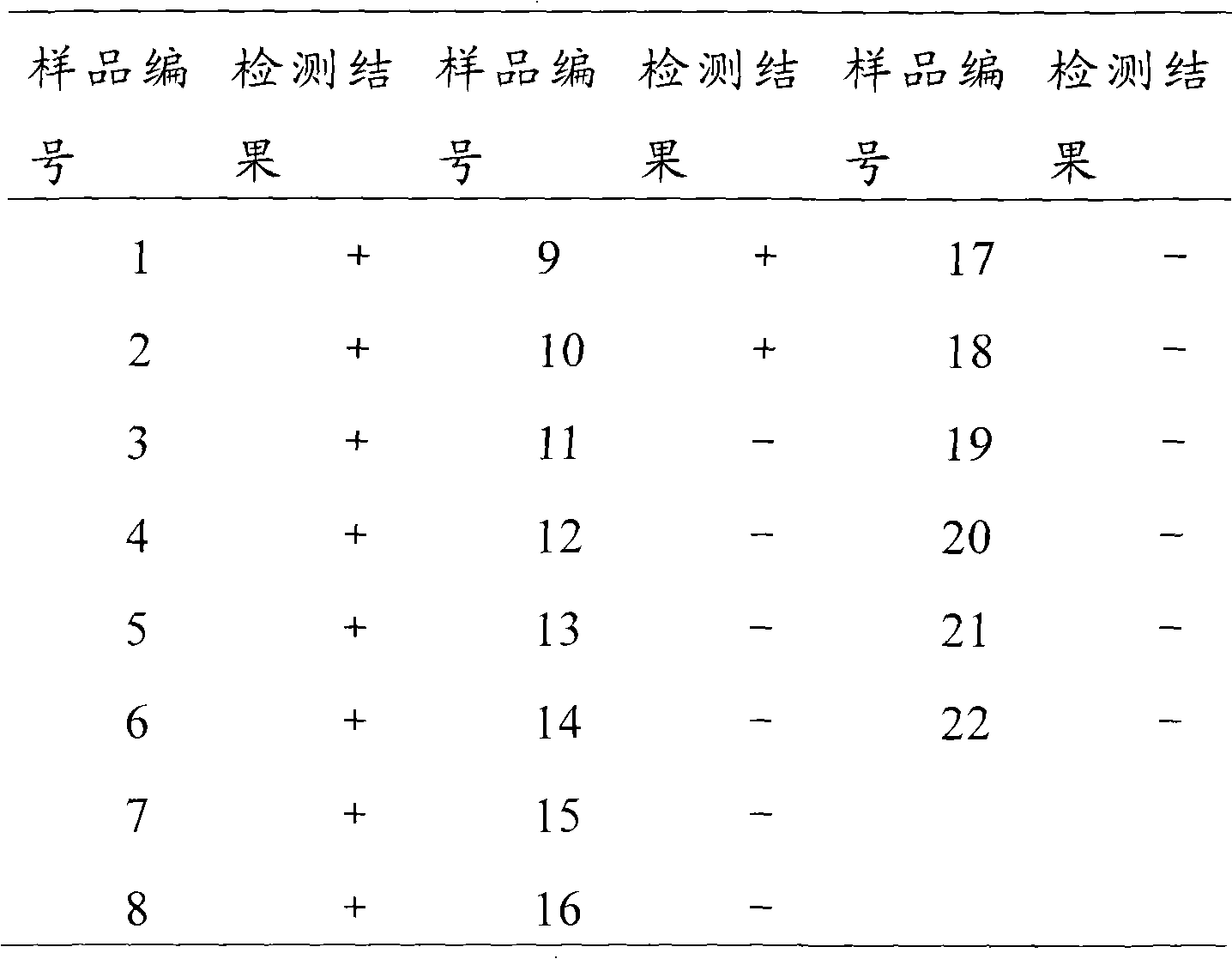

Ship unberthing and berthing device

InactiveCN106012977AHighly variableImprove crash performanceClimate change adaptationShipping equipmentHydraulic cylinderVertical plane

The invention discloses a ship unberthing and berthing device. The ship unberthing and berthing device is used for solving the problems that an existing anti-collision damping device on a wharf is poor in buffering effect, single in function and small in application range, and comprises at least two hydraulic cylinders and an operating center. Each hydraulic cylinder comprises a cylinder body and a piston rod, the tails of the cylinder bodies are hinged to a wharf, the cylinder bodies can rotate in vertical planes, the ends of the piston ends are used for pushing ships, the height of the ends of the piston rods is smaller than or equal to that of the tails of the cylinder bodies, and hoists for driving the cylinder bodies to rotate are arranged on the wharf and controlled through the operating center. According to the ship unberthing and berthing device, corrosion resistance and damping generated during berthing of ships are completed through contracting of the piston rods of the hydraulic cylinders, ships are pushed away from the wharf through stretching of the piston rods, the double functions are achieved, and the corrosion resistance and the damping performance are obviously improved compared with existing devices such as scrapped tires; due to the rotatable cylinder bodies, the ends of the piston rods are variable in height to adapt to unberthing and berthing of ships with different tonnages and different ship side heights.

Owner:ZHEJIANG INT MARITIME COLLEGE

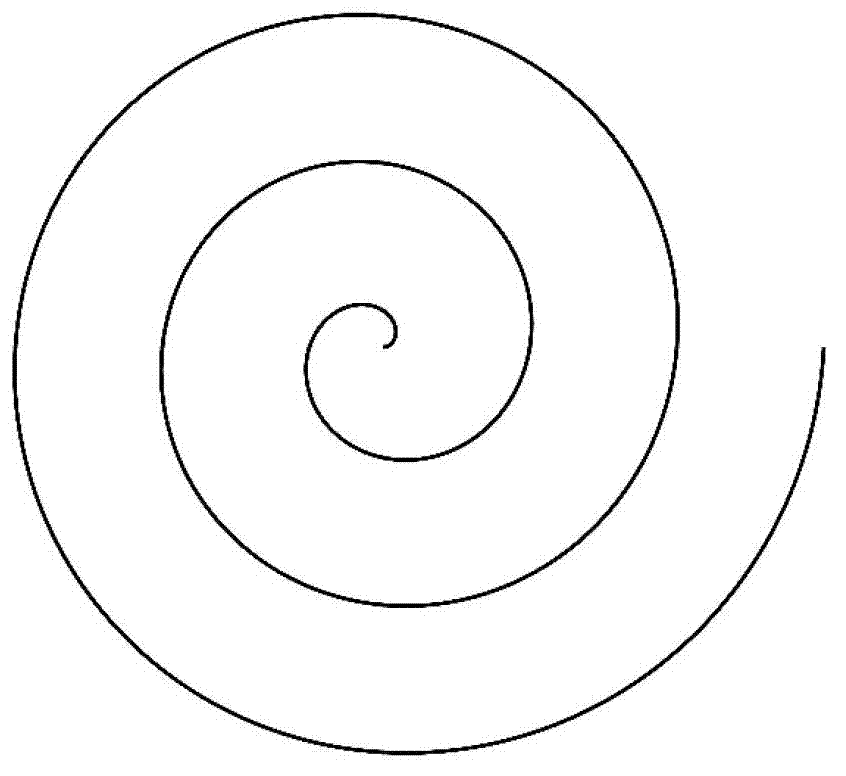

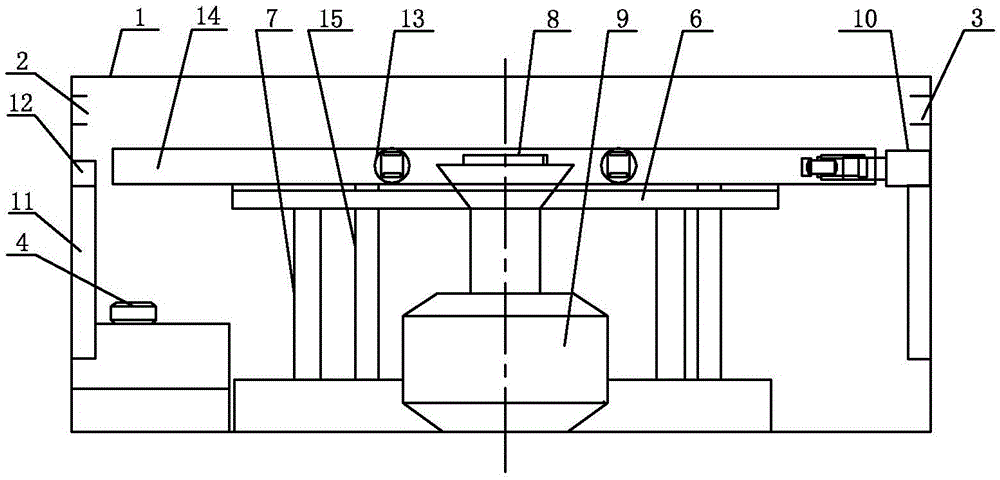

Helix machining path for numerical-control small tool polishing

InactiveCN102873628AImplementation angleReduce mistakesPolishing machinesGeneration processNumerical control

The invention relates to a helix machining path for numerical-control small tool polishing, belongs to the technical field of optical machining, and aims to solve the problem that the existing helix polishing path easily causes large medium-frequency error. A novel discrete helix machining path no longer maintaining constant angle increment and radius increment in generation process is constructed by introducing weight factors, the helix machining path is composed of n discrete points under a polar coordinate system with a polar angle theta and a radius coordinate value r and is generated from the center to outside sequentially, distance from the helix machining path to the center is largened sequentially, and accordingly two medium-frequency errors, namely concentric-circle-shaped corrugated error and radial corrugated error related to surface shape of a workpiece, can be reduced, and precision of the optical workpiece is further increased.

Owner:TSINGHUA UNIV

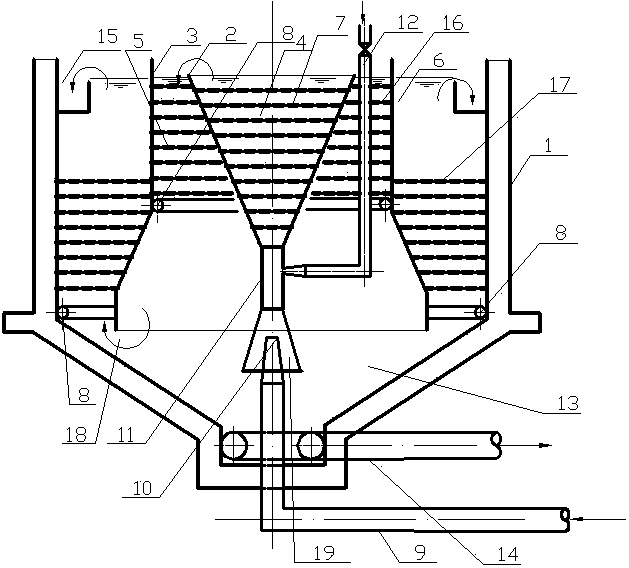

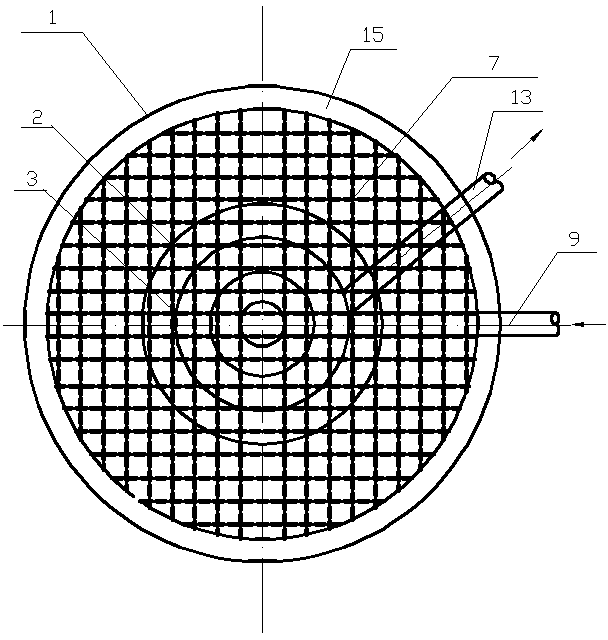

Aerobic granular sludge integrated sewage treating device and method

ActiveCN104310584ASimple structureEasy constructionBiological treatment apparatusTreatment with aerobic and anaerobic processesWater dischargeAeration system

An aerobic granular sludge integrated sewage treating device is disclosed. The device comprises a water feeding pipe, aeration systems and a sludge discharging perforated pipe. The device also comprises a cylindrical tank body. The center of the cylindrical tank body is provided with a cone reaction drum. The periphery of the cone reaction drum is provided with cylindrical separation plates. The cone reaction drum is the first reaction chamber. The space between the cone reaction drum and the cylindrical separation plates is the second reaction chamber. The space between the cylindrical separation plates and the cylindrical tank body is the third reaction chamber. Each reaction chamber is provided with a plurality of layers of mesh plates which are arranged horizontally. The bottom of the cone reaction drum is provided with a water-gas mixing short pipe. The water-gas mixing short pipe is connected to a gas feeding pipe. The lower end of the water-gas mixing short pipe is provided with a frustum cone-like water feeding cavity. The outlet of the water feeing pipe is horizontally arranged, is in the frustum cone-like water feeding cavity, and is provided with a nozzle. The lower end of the cylindrical tank body is provided with a cone. The bottom of the cone is connected to the sludge discharging perforated pipe. The top edge of the inner wall of the cylindrical tank body is provided with a water discharging groove. The device has characteristics of simple configuration, construction convenience, small occupied space, convenient running, good quality of discharged water, low manufacturing cost, and low running cost.

Owner:中国市政工程西北设计研究院有限公司

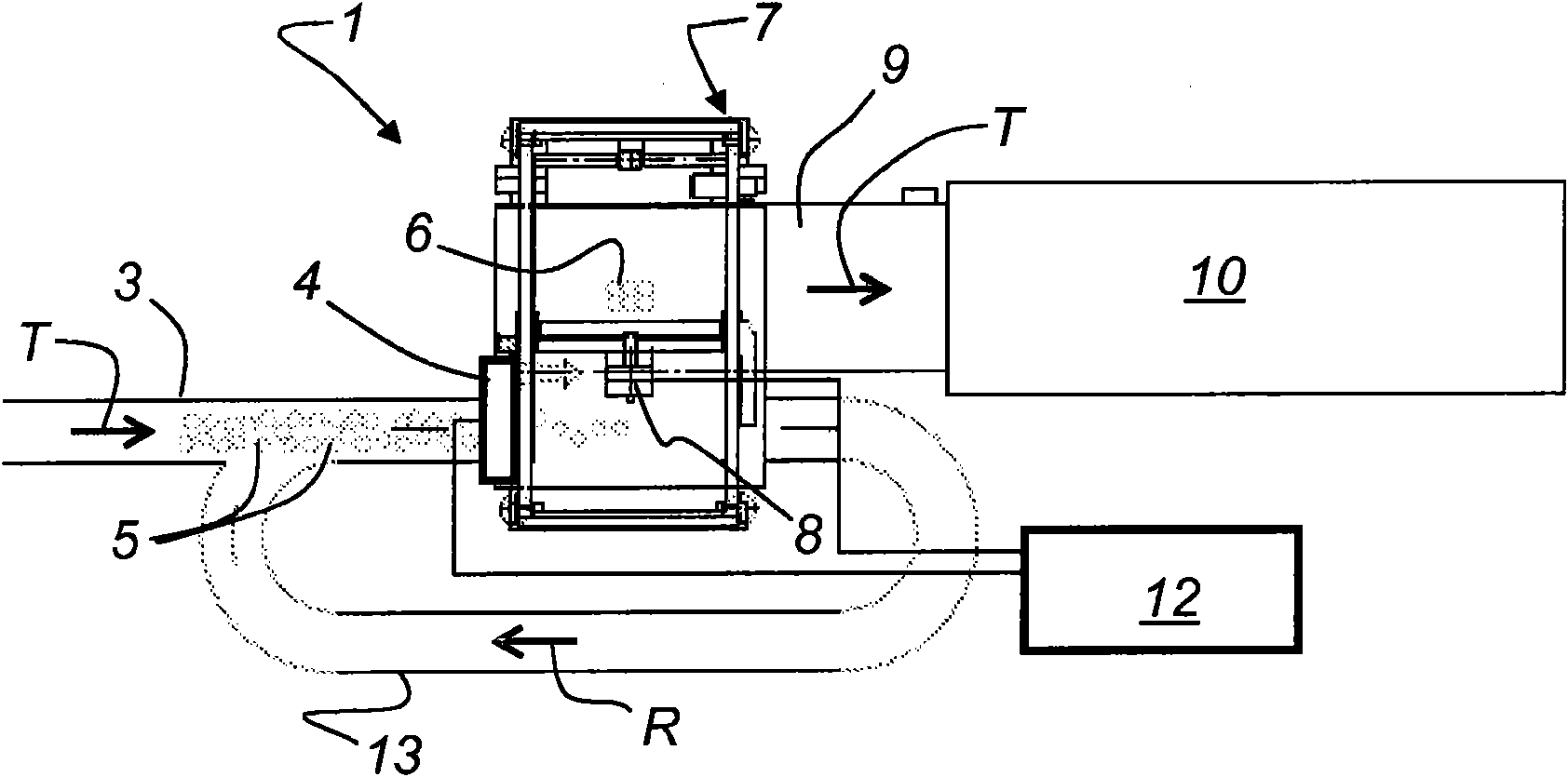

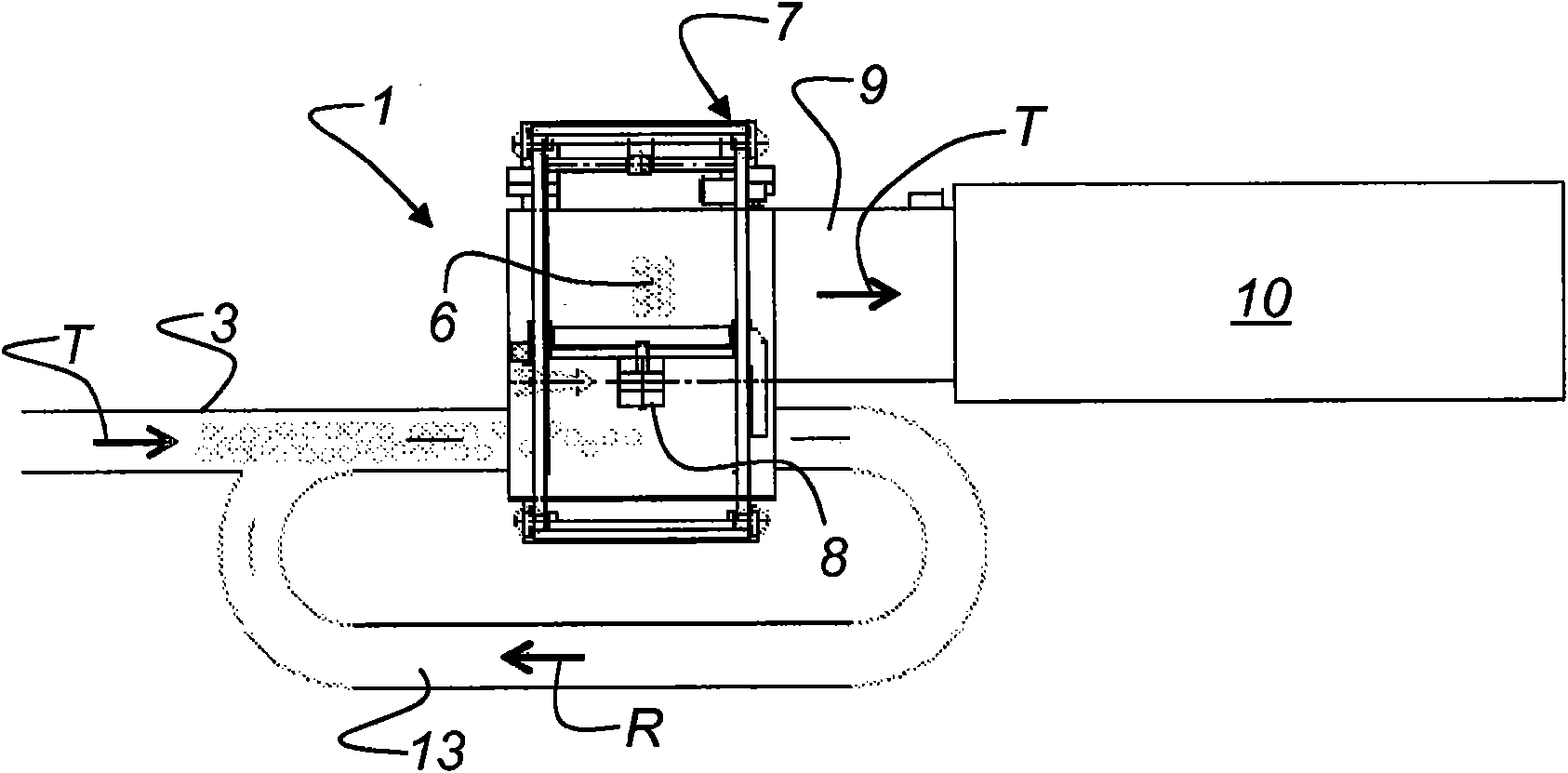

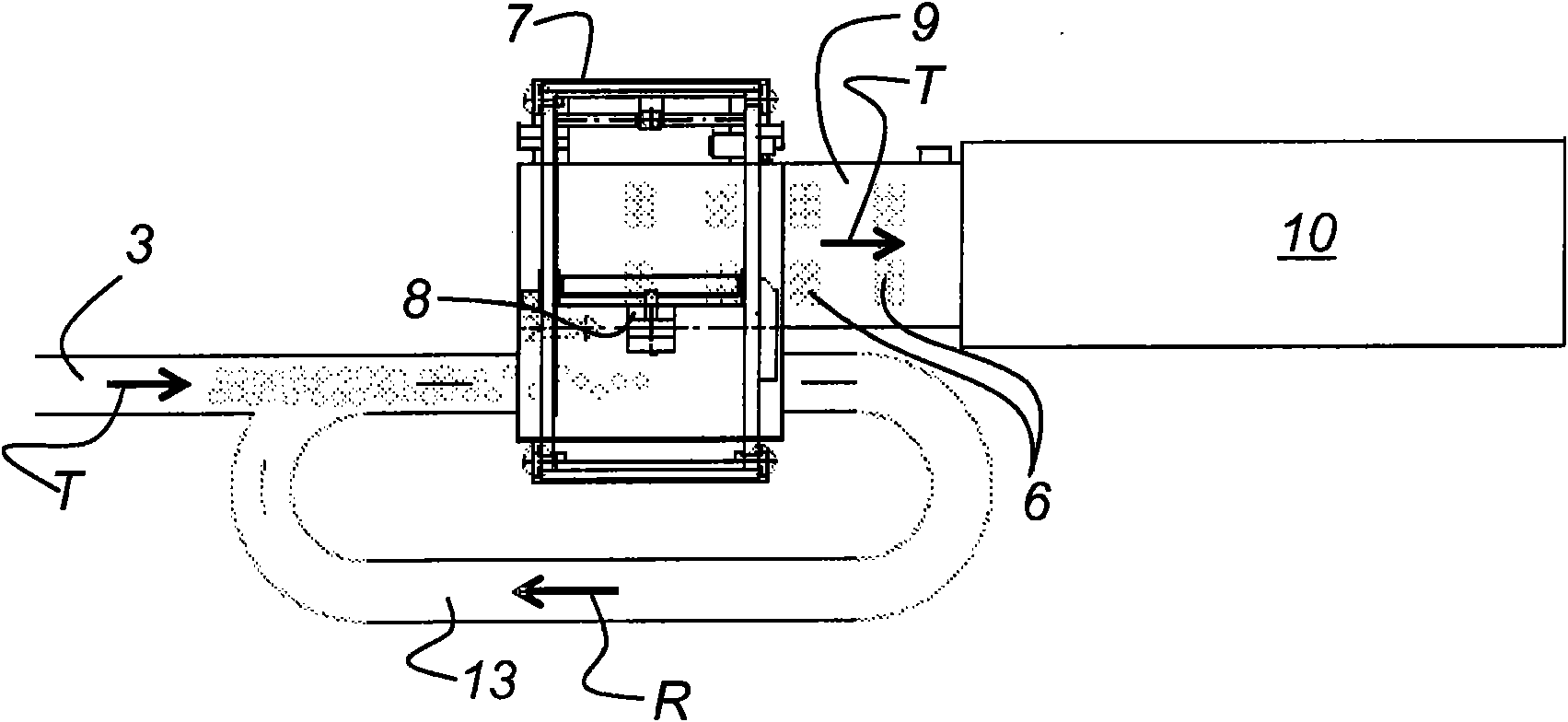

Device and method for composing packages for a packaging machine

The invention relates to a device (1) having at least one inlet conveyor belt (3) for loose, un-grouped articles (5), and at least one grouping device (7) for the loose, un-grouped articles (5) for the orderly composing of articles. An outlet conveyor belt (9) is associated with the grouping device (7), said outlet conveyor belt (9) feeding the articles thereon grouped without containers to a packaging device (10). The invention also discloses a method.

Owner:KRONES AG

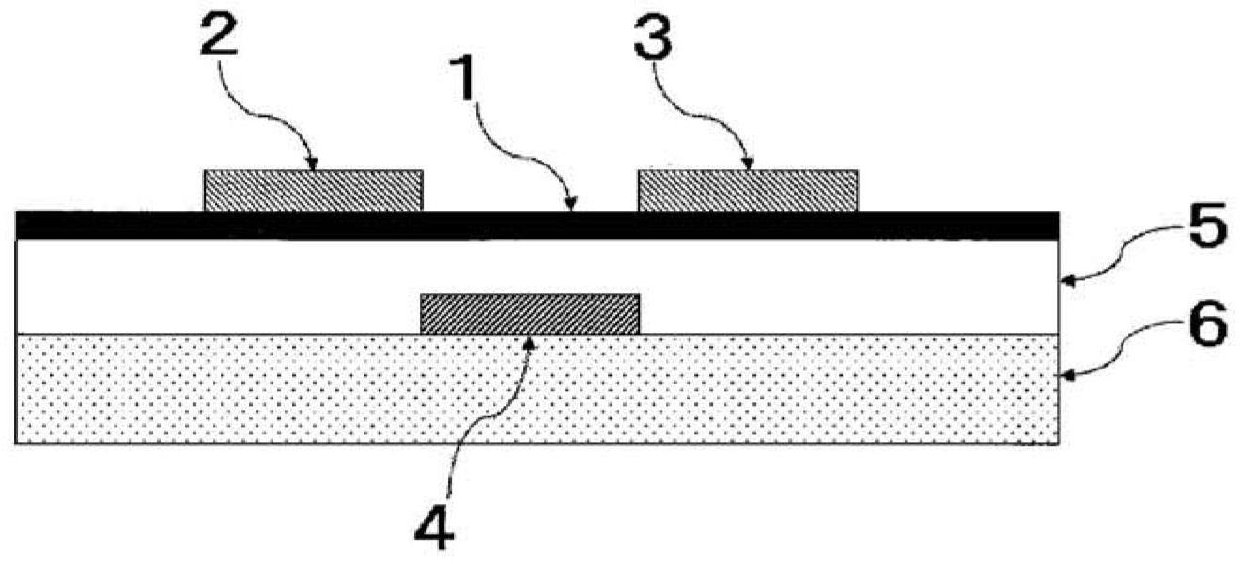

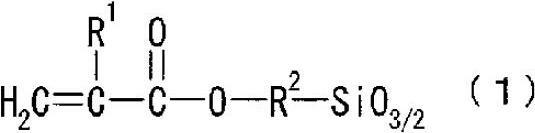

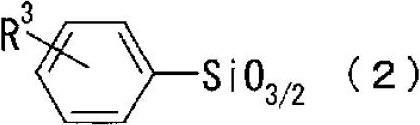

Photosensitive Resin Composition

InactiveCN102597879AExcellent resistance to changes over timeHighly variablePhotomechanical apparatusSemiconductor/solid-state device manufacturingCarbon numberHydrogen atom

Disclosed is a photosensitive resin composition-that can form a minute pattern by means of photolithography, can form a insulating film without heat treatment above 200 DEG C, and has no problems of carrier being trapped and charge mobility decreasing when used as a gate insulating film of an organic thin-film transistor-containing a photo-radical generating agent and a polysiloxane compound having units represented by the belowmentioned general formulae (1-4). (In formula 1, R1 represents a hydrogen atom or a methyl group, and R2 represents an alkylene group having a carbon number of 1-5 that may have a substituent alkyl group. In formula 2, R3 represents a hydrogen atom or an alkyl group having a carbon number of 1-4. In formula 3, R4 represents an alkyl group having a carbon number of 1-6 or a cycloalkyl group having a carbon number of 5-6. In formula 4, R5 represents a hydrogen atom or an alkyl group having a carbon number of 1-4.)

Owner:ADEKA CORP

Actively unfolded parachute

The invention provides an actively unfolded parachute. The actively unfolded parachute is characterized by comprising a compressed air bottle, wherein an outlet of the compressed air bottle is butted with a three-way pipe; the three-way pipe is connected with a pressure meter; the other end of the pressure meter is connected with a one-way control valve; a supporting airbag is a telescopic part and is respectively connected with the one-way control valve and a stressed load lock through a clamping barrel in a clamping way; the stressed load lock is respectively connected with parachute ribs through being matched with the clamping barrel; and the parachute ribs are attached onto a speed reduction surface. According to the actively unfolded parachute, the conventional way of opening the parachute by the resistance force formed by a retarder parachute and the air is given up, and the compressed air carried by the parachute is used to provide the parachute opening function. The passive unfolding problem of the conventional parachute is mainly solved, and the actively unfolded parachute can be opened without external force as the kinetic energy is provided by the compressed air carried by the actively unfolded parachute. Therefore, the passive unfolding mode of the conventional parachute is changed.

Owner:余自玄

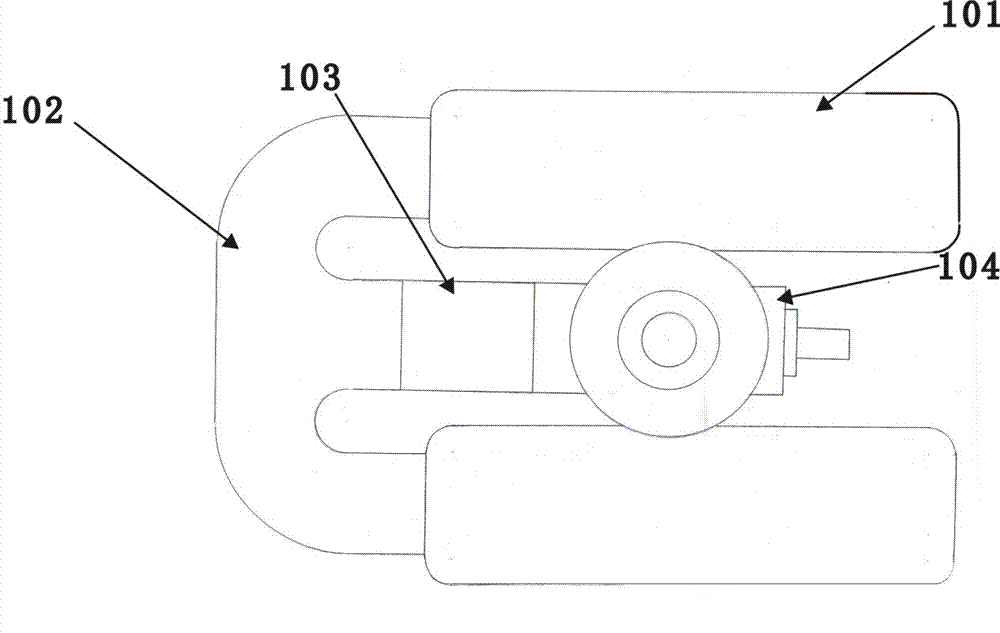

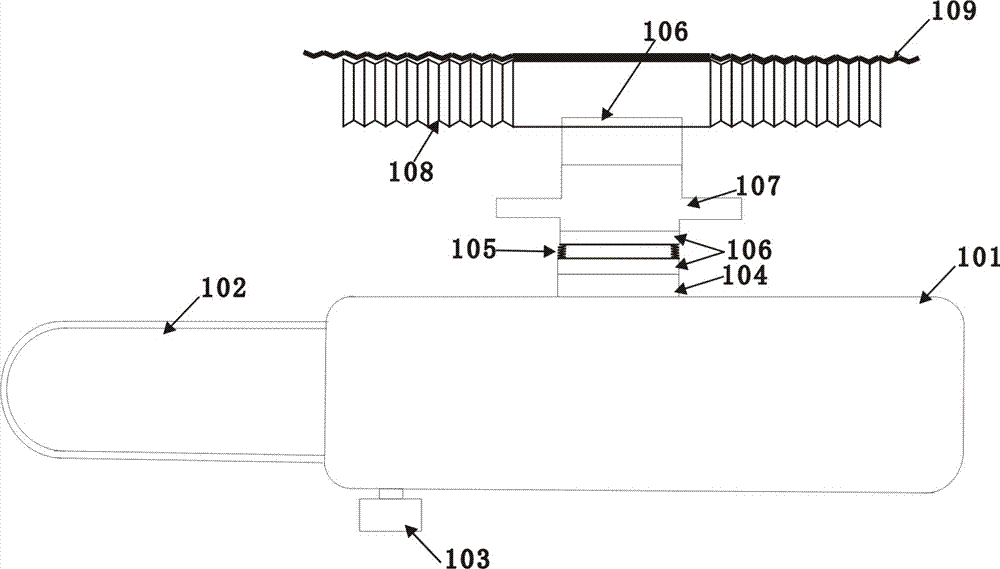

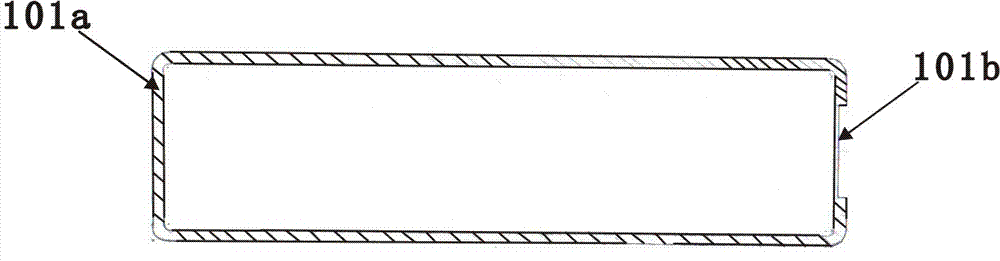

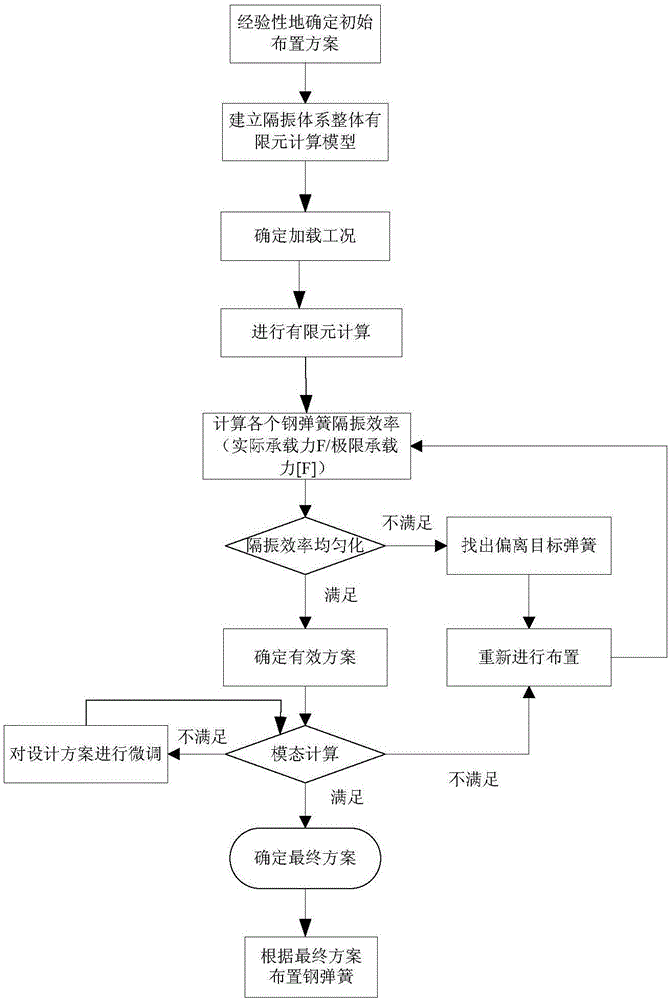

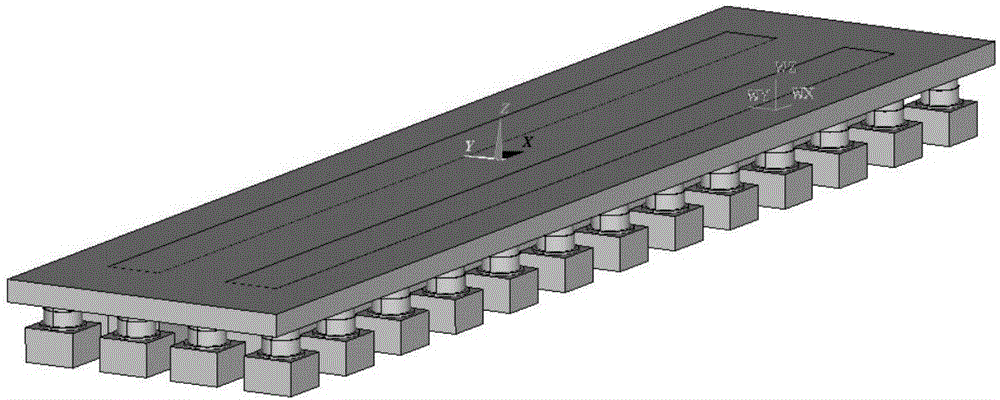

Large-scale vibration engineering control device optimization arrangement method

ActiveCN106650155ASolve the optimization layoutAvoid homogeneous layoutGeometric CADDesign optimisation/simulationEngineering controlsEngineering

The invention discloses a large-scale vibration engineering control device optimization arrangement method. A control device refers to a steel spring vibration isolator. The method includes the steps of (1), determining a steel spring initial arrangement scheme according to the actual engineering; (2), building an integral finite element calculation model of a vibration isolation system; (3), determining a loading condition; (4), calculating actual bearing capacity F of each steel spring by software through finite element calculation; (5), calculating vibration isolation efficiency Etan of each steel spring according to the formula Etan=actual bearing capacity F / ultimate bearing capacity[F]; (6), uniformizing the vibration isolation efficiency and calculating the uniform vibration isolation efficiency[Eta] according to the formula [Eta]=(Eta<1>+Eta<2>+Eta<3>+...+Eta<n>) / n; (7), if the vibration isolation efficiency Etan meets the formula (Eta<n>-[Eta]) / [Eta]< / =10%, then determining the effective scheme; (8), carrying out model calculation and analysis to the whole vibration isolation model; (9), determining the final scheme if requirement for model is met, in other words, the modal calculation fundamental frequency error is lower than 10%; and (10), arranging the steel springs according to the determined final scheme.

Owner:国机集团科学技术研究院有限公司

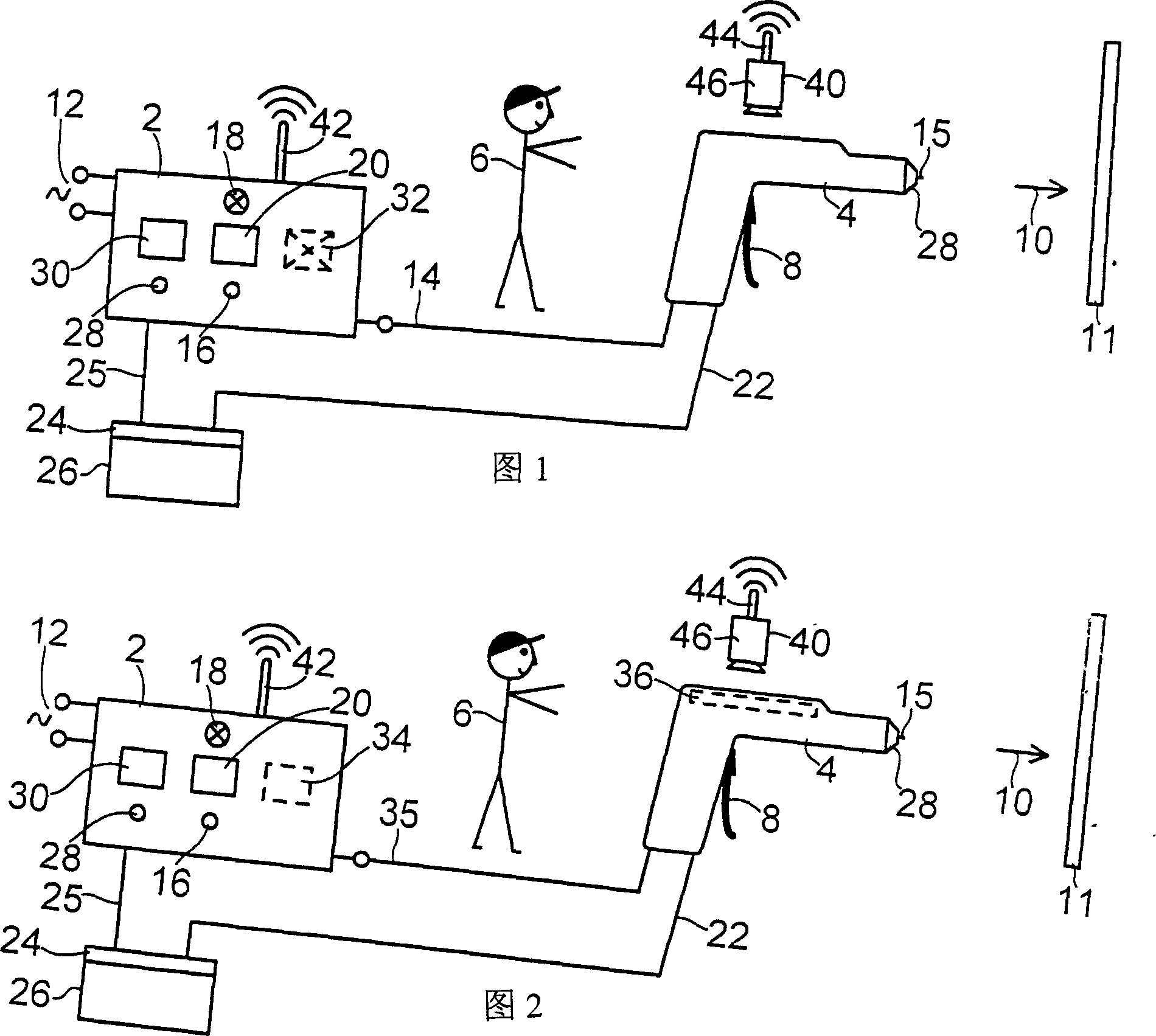

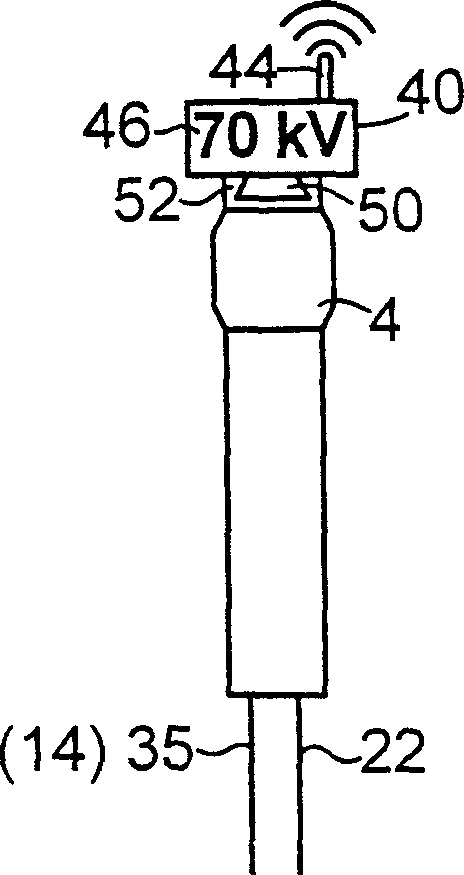

Spray coating device

InactiveCN1623675AHighly variableAdjustable distanceLiquid spraying plantsSpraying power supplyDisplay deviceSpray coating

The pistol (4) has a high tension electrode (15) to coat the work (11) when the trigger (8) is pressed. The high tension generator (32) is in a control unit (2) connected to an electrical supply (12) and data on indicator panels (20,30) is transmitted to a remote indicator unit (40) by radio (42,44).

Owner:ITW表面技术两合有限公司

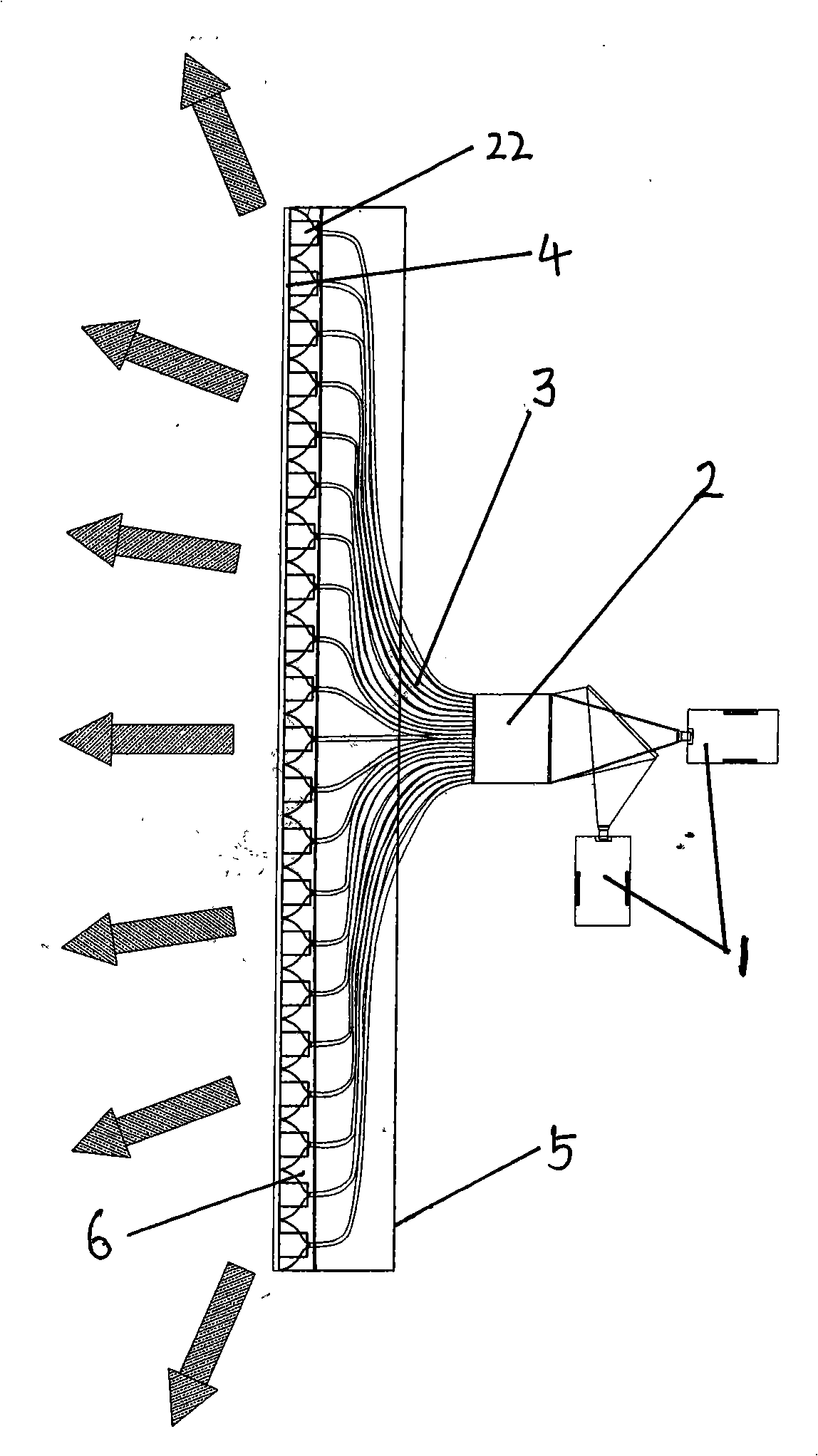

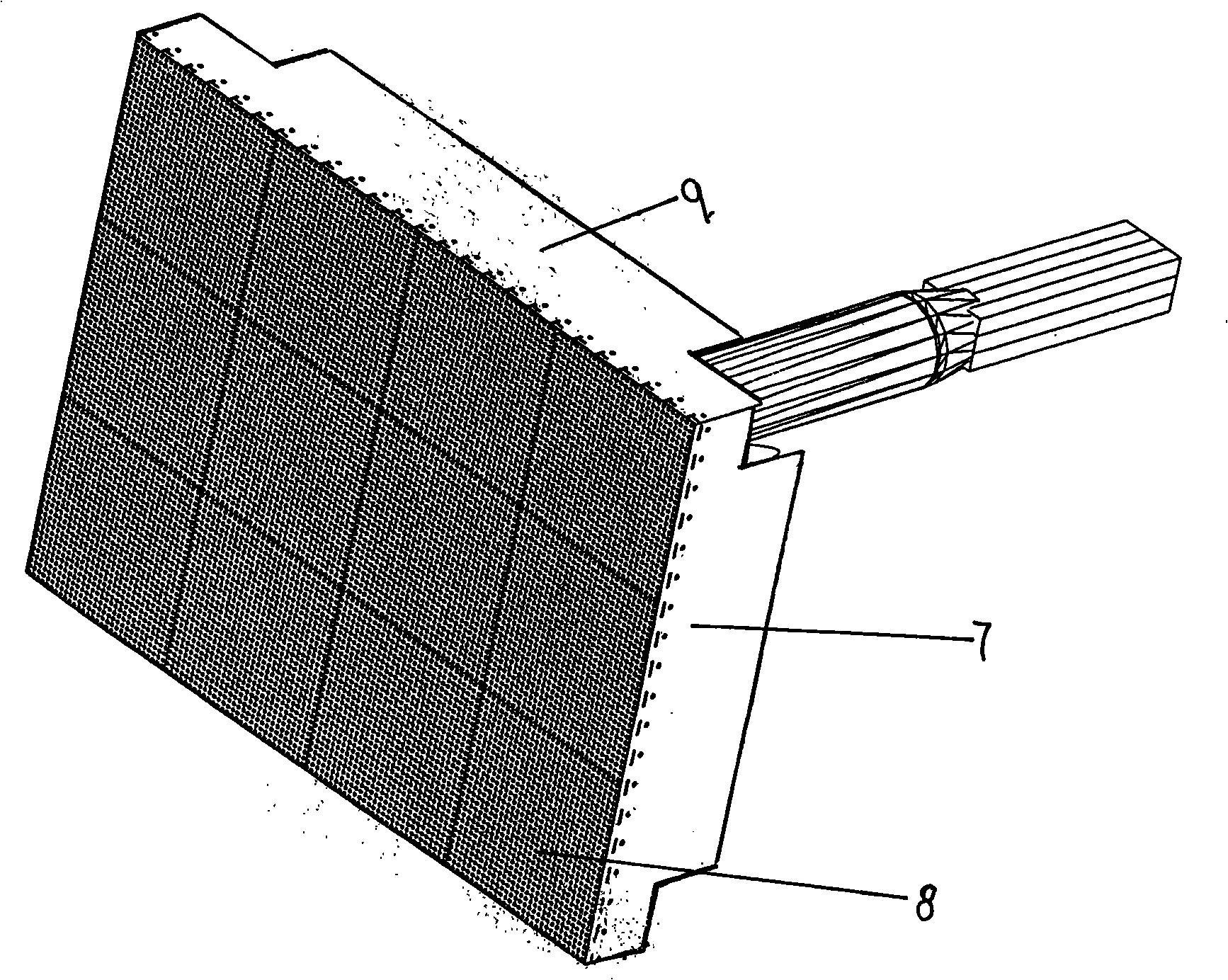

Optical fiber display screen and manufacturing method thereof

InactiveCN101299077AIncrease brightnessHigh clarityTelevision system detailsProjectorsMultiple formsCooking & baking

The present invention discloses an optical fiber display screen and a preparing method thereof. The invention is characterized in that the screen body is composed of an outer frame of the display screen and a casing. The casing is composed of a plurality of casing units, and each casing unit is composed of a plurality of module units, side boards of the casing, a fastening connecting rod and a connector. The module unit is composed of a clip, a lens and a buckle. The preparing method is that the optical fibers at projection end of ten thousands of optical fibers and the auxiliary device are fastened to a total bundle end surface with methods of veneering and baking. Each screen installation module unit uses the methods of veneering and auxiliary device to make the projection end to a module bundle end. The same method is used for preparing a casing bundle end. Finally the casing bundle end is accumulated to a total bundle end surface of screen. The total bundle end surface at the projection end is prepared with the methods of veneering and auxiliary device. Furthermore the total bundle surface at the projection end is grinded and polished to form a surface. The optical fiber display screen according to the invention has advantages of high brightness, high resolution, lifelike color, wide visual angle, strong convertibility, low energy consumption, strong hostile environment resistance, long service lifetime, convenient assemblage, low maintenance cost, multiple forms of connecting signals and the like.

Owner:都志军

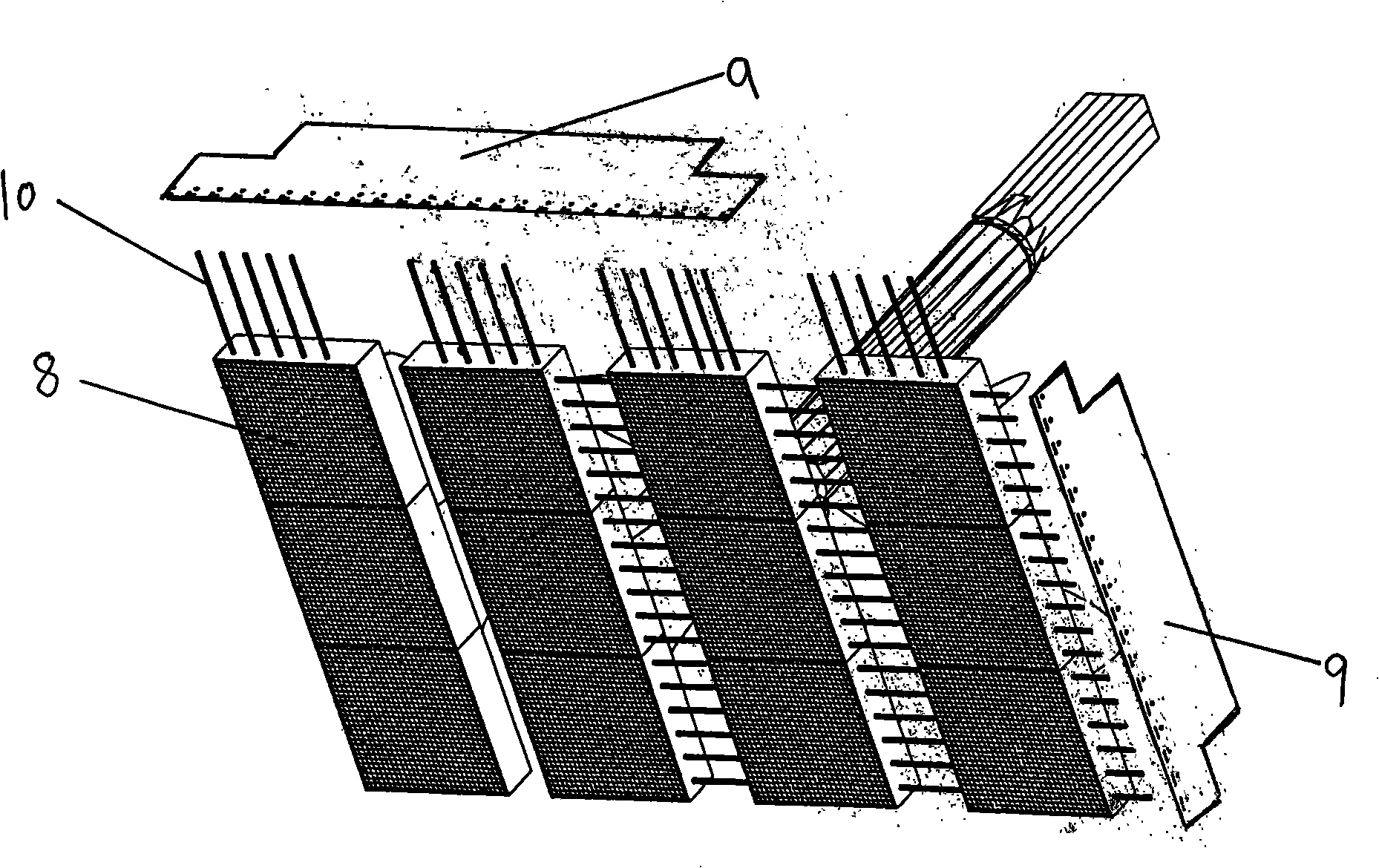

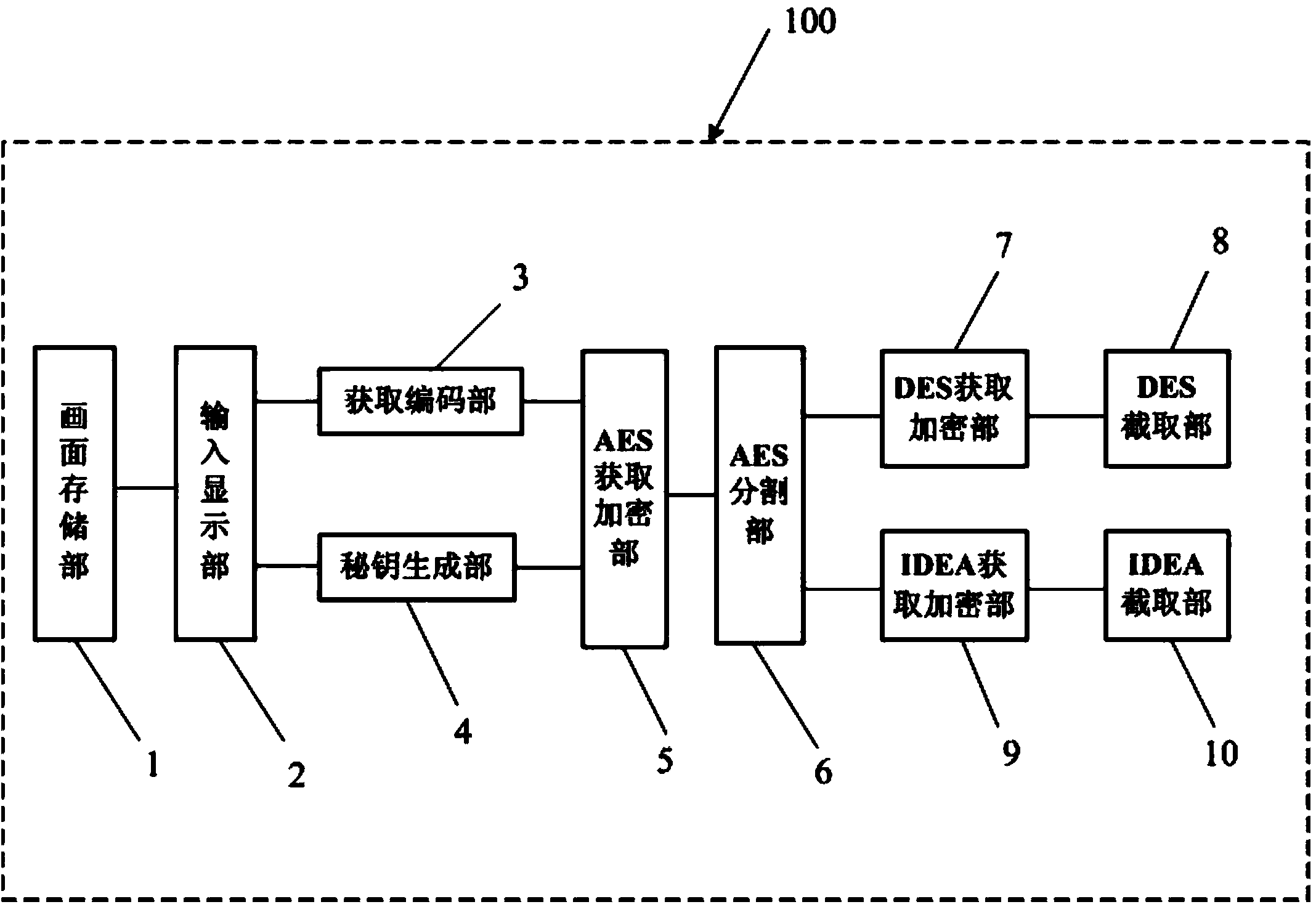

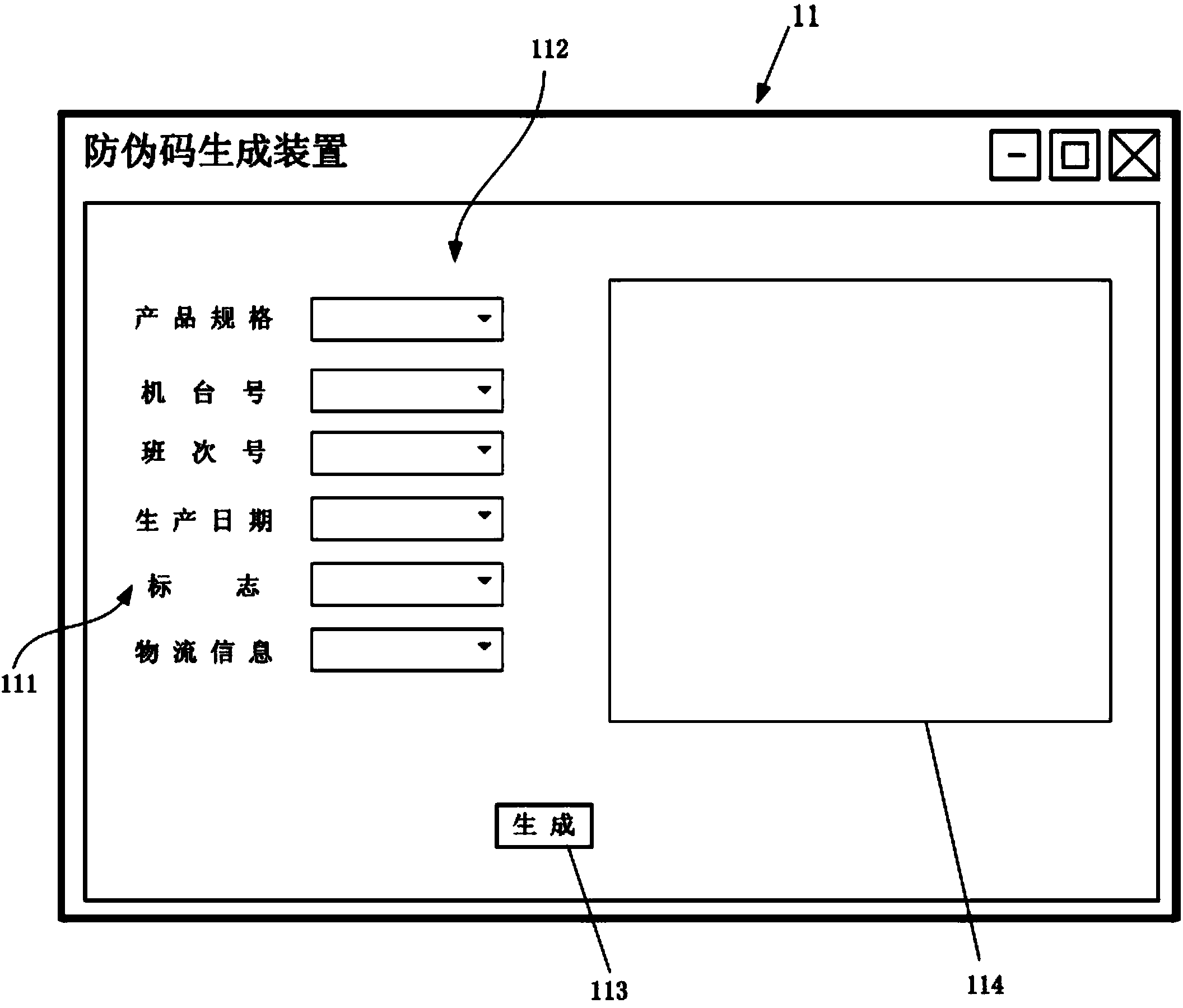

Anti-counterfeit code generating device

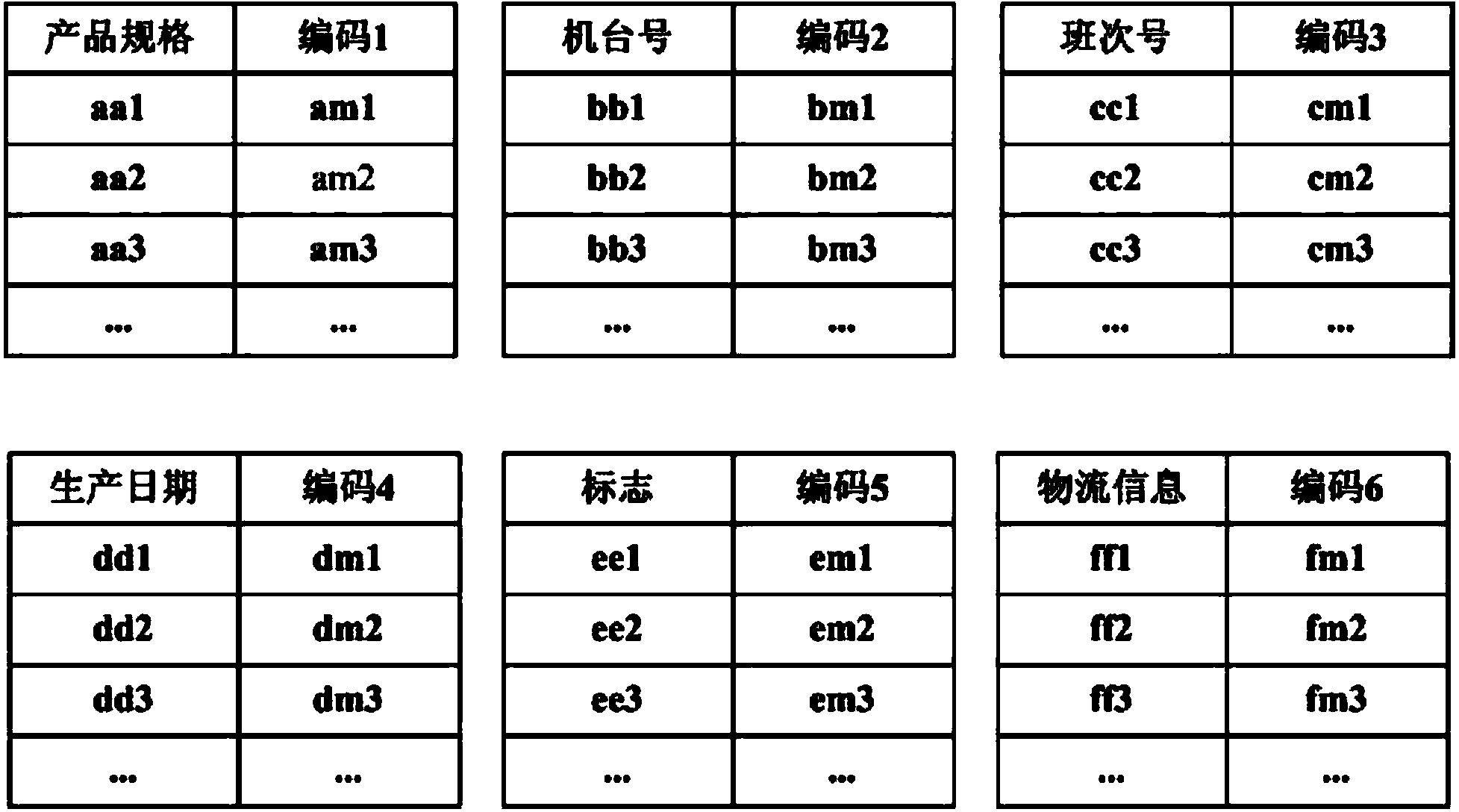

InactiveCN103824197AHigh encryption strengthAvoid crackingUser identity/authority verificationCommerceAdvanced Encryption StandardSerial code

The invention provides an anti-counterfeit code generating device. The anti-counterfeit code generating device is characterized by comprising a picture storage part, an input display part, a code acquiring part, a secret key generating part, an AES (advanced encryption standard) acquiring and encrypting part, an AES cutting part, a DES (data encryption standard) acquiring and encrypting part, a DES cutting part, an IDEA (international data encryption algorithm) acquiring and encrypting part and an IDEA intercepting part, wherein the code acquiring part is used for acquiring input product information, and encoding according to a certain predetermined rule so as to generate corresponding product serial numbers. The anti-counterfeit code generating device provided by the invention firstly encrypts a product serial number by an AES algorithm, and then divides the encrypted result obtained by the AES algorithm into two parts, wherein one part is encrypted by a DES algorithm so as to obtain a logistic anti-counterfeit complete code, and a logistic anti-counterfeit application code is intercepted from the logistic anti-counterfeit complete code; the other part is encrypted by an IDEA algorithm so as to obtain a product anti-counterfeit complete code, and a product anti-counterfeit application code is intercepted from the product anti-counterfeit complete code, so that compared with the prior art, the anti-counterfeit code generating device has the characteristics of high encryption intensity and difficulty in code cracking.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

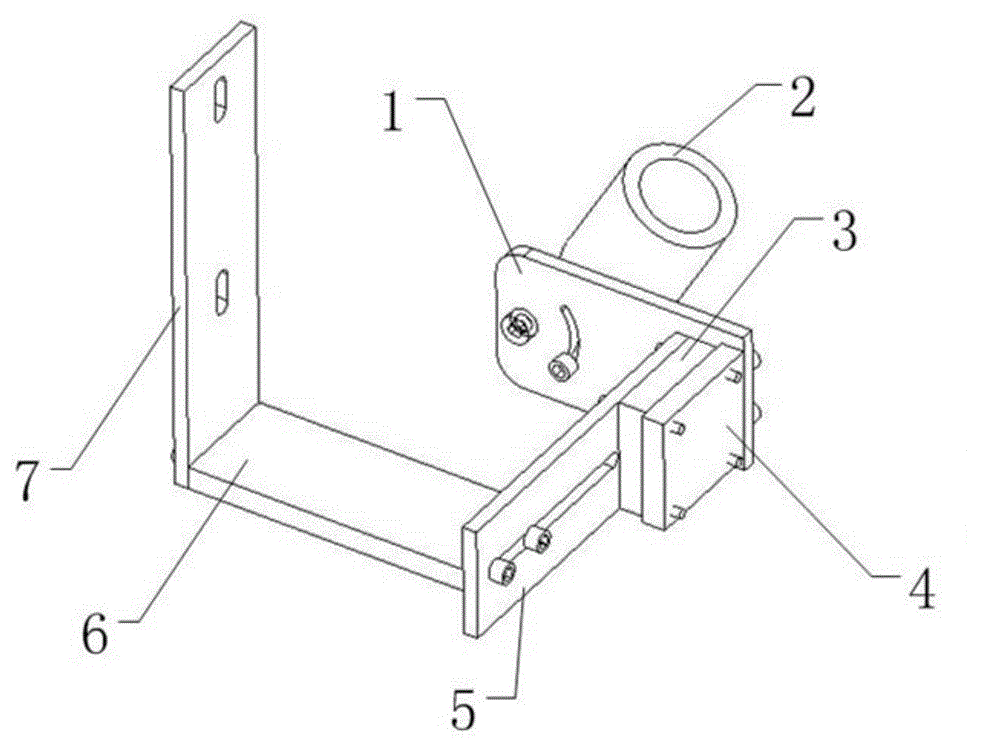

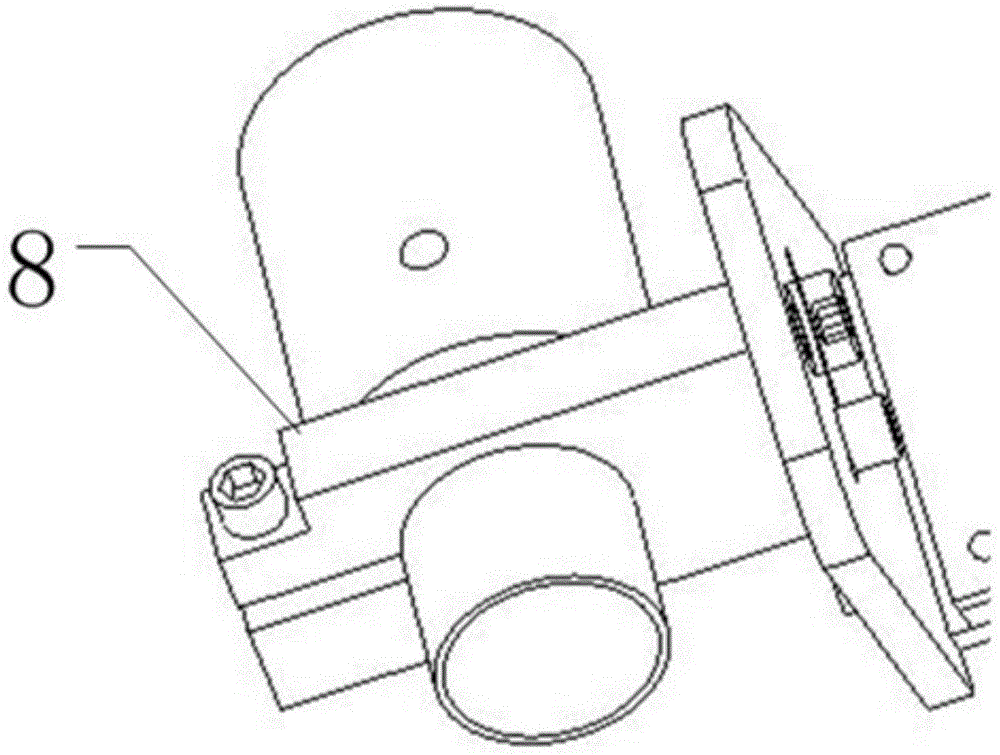

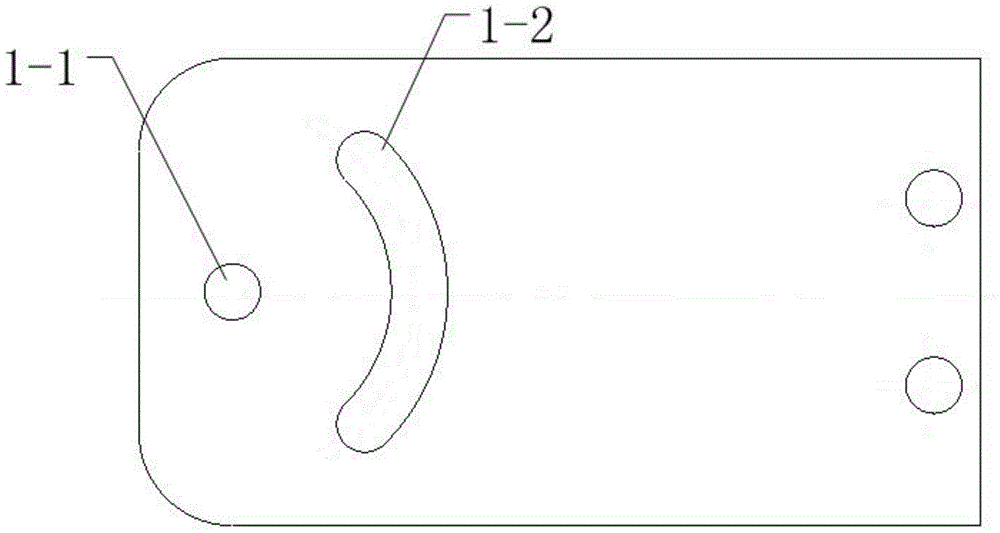

Adjustable fixture for fixing lens of temperature measurement device, and temperature measurement device

InactiveCN104568161ALarge adjustment rangeSimple supporting structureRadiation pyrometryElectrical and Electronics engineeringRadian

The invention relates to an adjustable fixture for fixing a lens of a temperature measurement device. The adjustable fixture comprises a fixing structure, a first plate, a second plate and a support structure, wherein the fixing structure is provided with a matching hole which penetrates through the fixing structure and is used for fixing the lens; a first hole and a second hole with a spacing of a are formed on any side, relative to a penetrating direction of the matching hole, of the fixing structure; a connecting hole and an arc groove are formed in the first plate; the arc groove takes the center of the connecting hole as the circle center and the length a as the set radian of the radius; the first hole is movably connected with the connecting hole; the second hole is matched with the arc groove; the first plate is connected with the second plate at a set angle; a linear guide groove is formed in the second plate; at least two third holes matched with the linear guide groove are formed in the support structure; and structures which penetrate through the linear guide groove and can obstruct the second plate are arranged in the third holes. The invention further relates to the temperature measurement device of the adjustable fixture. According to the adjustable fixture and the temperature measurement device, an adjustment range of the fixture is expanded; the adjustment accuracy is improved; and the adjustable fixture is simple in structure and easy to mount, and can be conveniently arranged on various temperature measurement occasions.

Owner:ZHEJIANG UNIV OF TECH

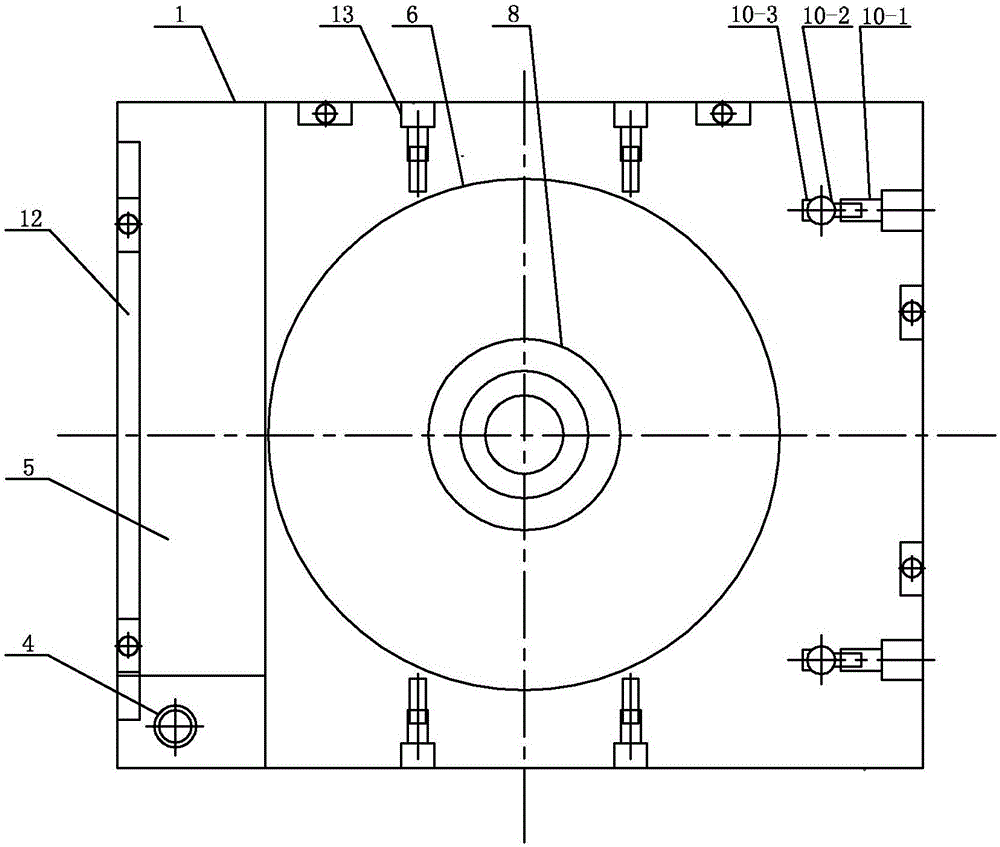

Laser edge scanning device capable of machining glass chip of any shape

The invention provides a laser edge scanning device capable of machining a glass chip of any shape, and relates to the field of solar cell module machining. The laser edge scanning device aims at solving the problems that due to the fact that in a traditional process for conducting edge scanning on the glass chip through lasers, the edge scanning parallelism can not be accurately controlled, the edge scanning accuracy is poor and the machining quality is influenced. According to the laser edge scanning device capable of machining the glass chip of any shape, an air-floating platform is in an annular shape; a vacuum suction cup is arranged in the middle in a shell; the lower end of the vacuum suction cup is arranged on the upper surface of the bottom end face of the shell through a rotatable support; the upper end of the vacuum suction cup penetrates out of a central hole of the air-floating platform; a positioning device is arranged above the air-floating platform; two universal push handles are fixedly connected with the upper end of an adjustable support which is arranged on the right side wall of the shell; the length direction of each universal push handle is perpendicular to the length direction of the adjustable support; and the two universal push handles are symmetrical about the central line, in the length direction, of the shell. The laser edge scanning device is used for machining the glass chip.

Owner:HANERGY MOBILE ENERGY HLDG GRP CO LTD

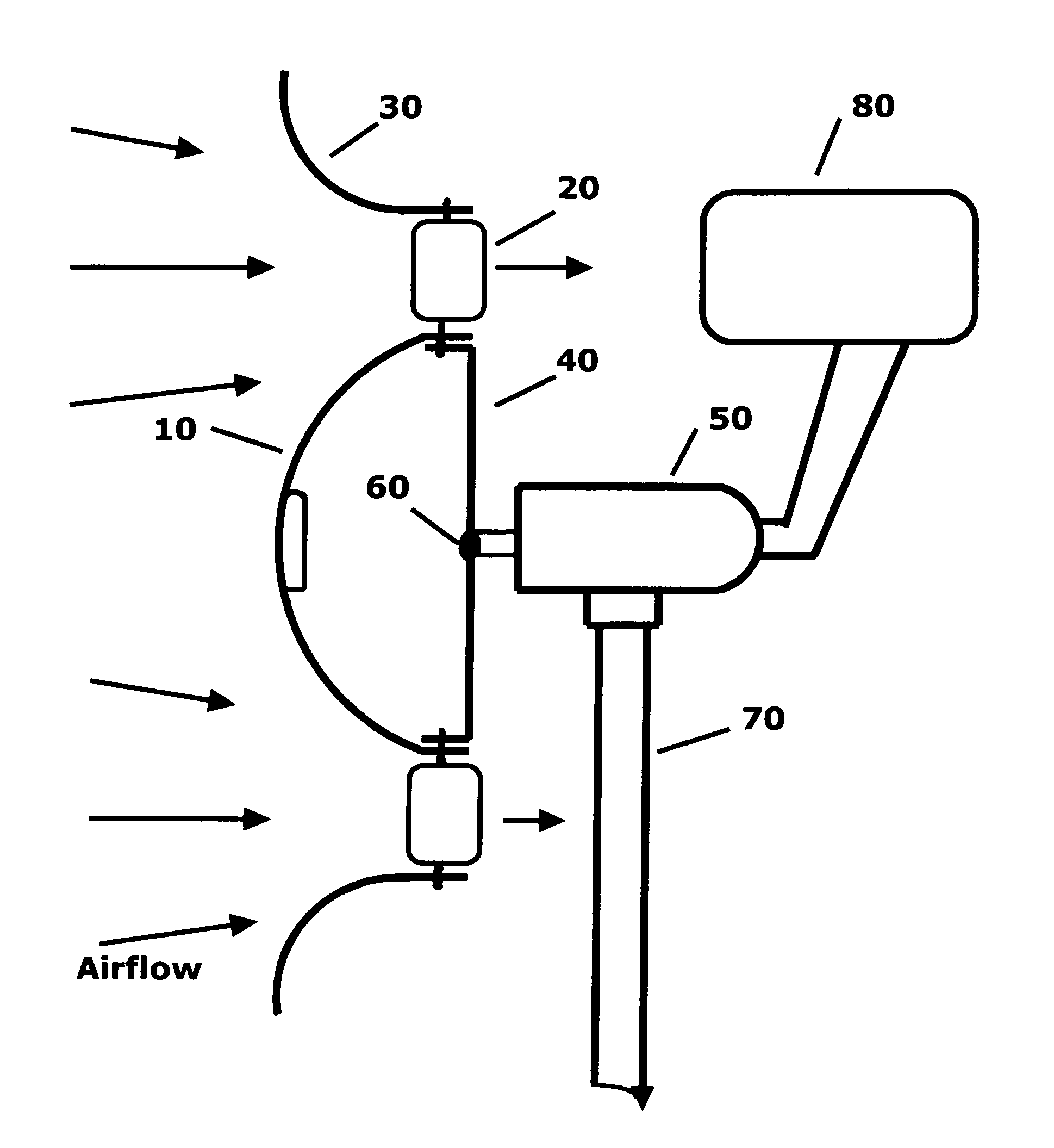

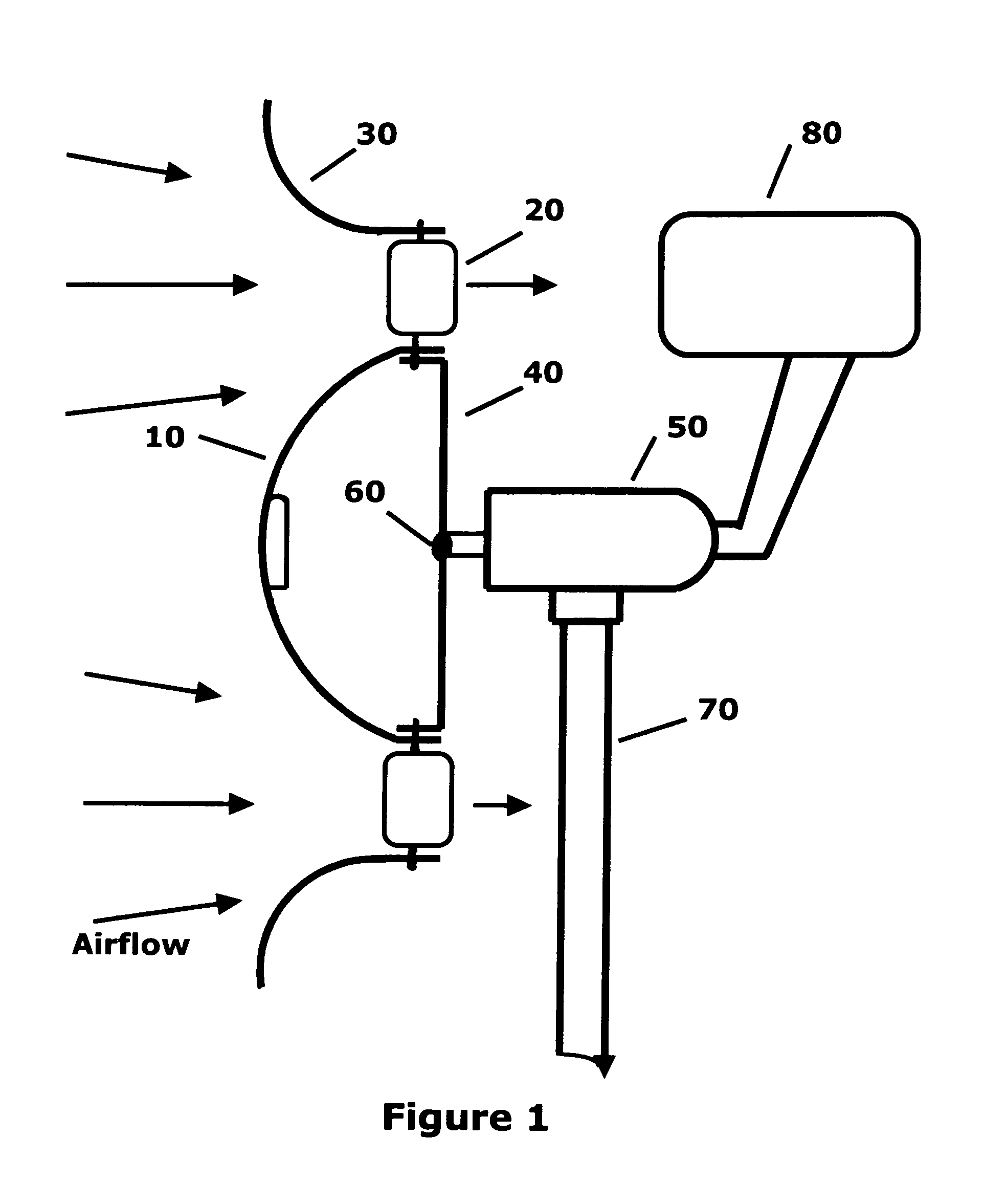

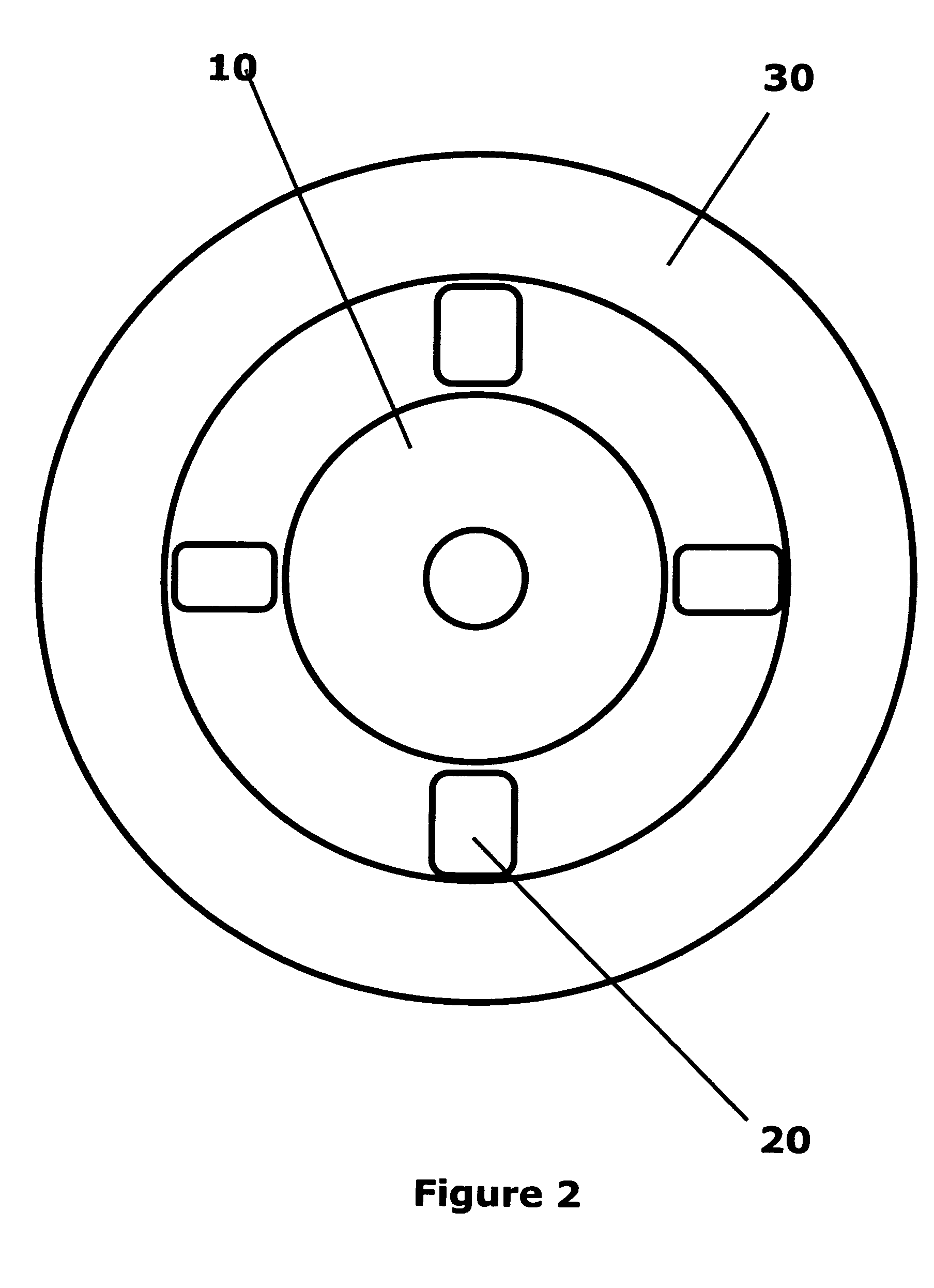

High-torque wind turbine

InactiveUS20160097370A1Increase airflowIncrease power outputPump componentsReaction enginesLow speedHigh torque

A high-torque turbine system receives and converts low to higher speed wind or airflow into mechanical work or electric power; consisting of a number of sail or airfoil blades or blade portions located near the outer periphery having extended moment arms for increased torque, that rotate around an center axis that is parallel to the airflow, wherein the blades receive wind directly, from a center deflector that directs wind received in the center outward to the blades, or from airflow directed externally from man-made, natural or structural sources, wherein the turbine system outputs mechanical work or electrical power.

Owner:RODGERS JAMES L +1

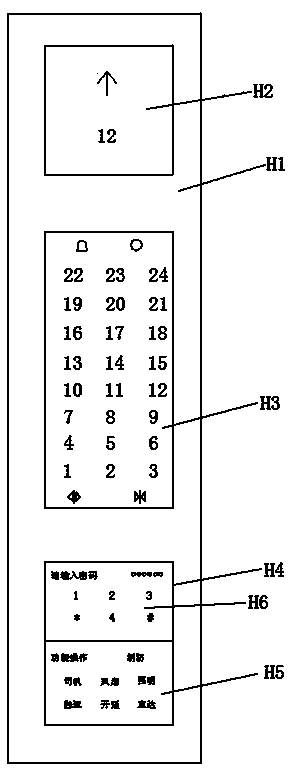

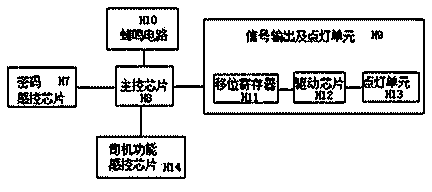

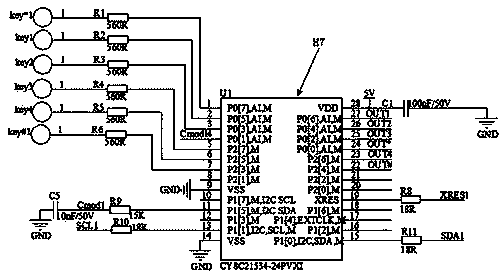

Elevator induction type special control device

InactiveCN104044966AEasy to useBeautiful appearanceElevatorsEnergy efficiency in elevatorsCapacitanceSurface mounting

The invention relates to the technical field of elevator devices, in particular to an elevator induction type special control device which comprises a control box panel. A display portion, a floor operation portion and a driver box operation portion are arranged on the control box panel. The driver box operation portion comprises a password input portion and a function operation portion. By the adoption of the structure, firstly, the elevator induction type special control device is attractive and elegant in appearance and high in variability, corresponding driver functions can be achieved according to the demands of customers, that is, a self-reset button, a self-lock button and the like are arranged, six-number password unlocking control replaces existing key lock control, by setting the user-friendly password, an operator can more conveniently operate the elevator induction type special control device, and safety of the product is effectively improved; secondly, the elevator induction type special control device is manufactured and machined through surface mount production of an SMT device, and therefore manufacturing cost of the product is reduced, and the yield of the product is improved; finally, by the adoption of the capacitive sensing type touch technology, the control device has the advantages of being capable of saving energy, environmentally friendly, long in service life, easy to use and popularize and the like.

Owner:JIANGSU WELM TECH

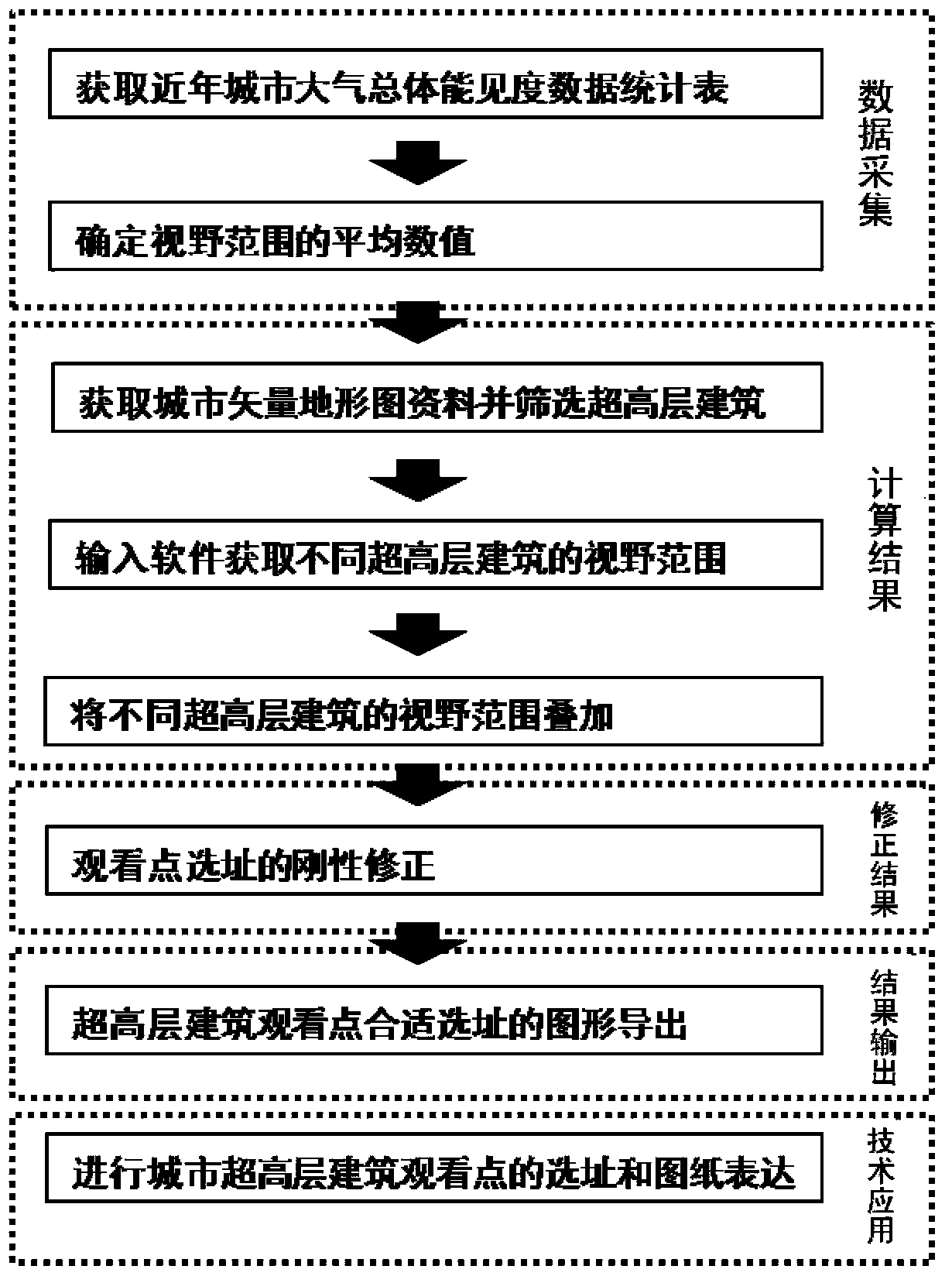

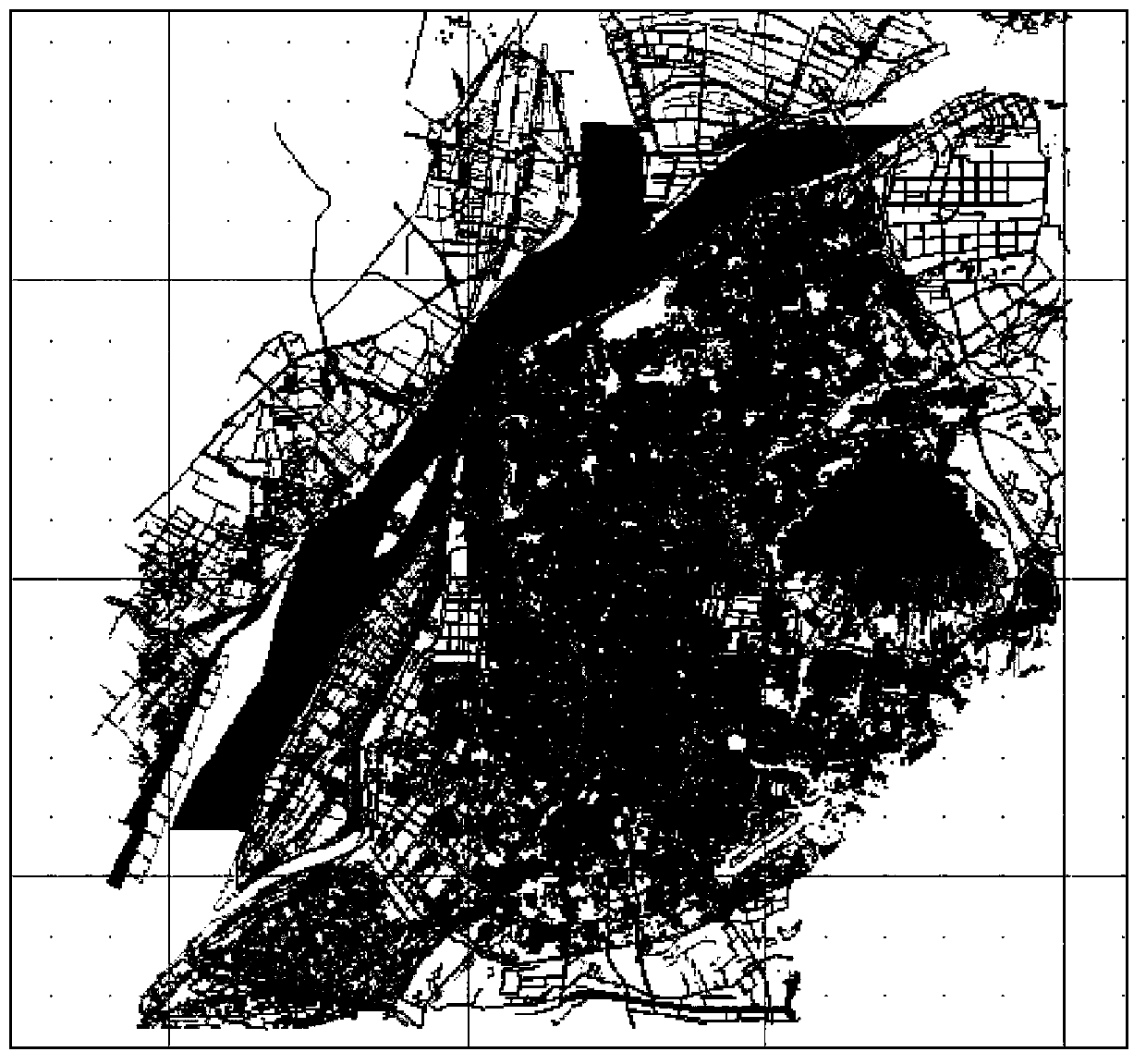

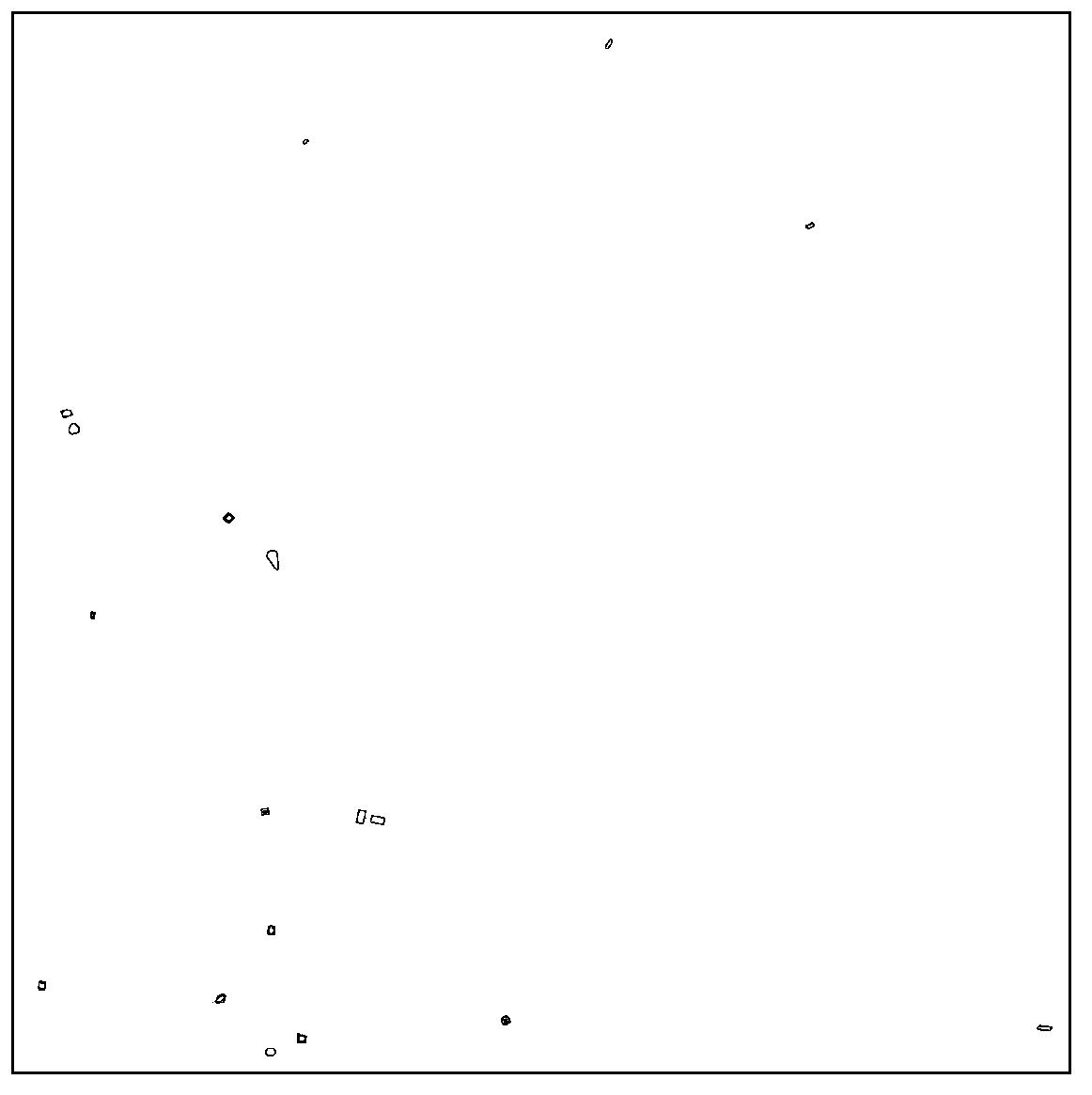

Site selection method for measuring and calculating city super high-rise building viewing point based on atmospheric visibility

The invention discloses a site selection method for measuring and calculating a city super high-rise building viewing point based on atmospheric visibility, and relates to the technical field of city planning. The method comprises the steps that firstly, a data statistical table of city atmosphere overall visibility in resent years is obtained, and an average value of the field of view is determined; then by screening city flat terrain data, city super high-rise buildings are obtained; based on the average value of the field of view, the optimal selected site of the viewing point is determined by the superposition of the fields of view of the different super high-rise buildings; finally, secondary superposition is conducted on a superposition result and city rivers, mountains, roads, large building facilities, historical buildings and the like, and the selected site of the viewing point is determined. On the basis of fully-quantified survey, statistics and calculation, the rational analysis result of the field of view of the city super high-rise buildings is obtained through the data, accordingly, the basis is provided for site selection of the super high-rise building viewing point, and the target of more reasonably and efficiently making use of the precious city space is achieved.

Owner:SOUTHEAST UNIV

Computer display capable of manually lifting

InactiveCN106499932AHighly variableSolve the problem that the height cannot be adjustedStands/trestlesReciprocating motionDisplay device

The invention discloses a computer display capable of manually lifting. The computer display capable of manually lifting comprises a computer display, a support column used for supporting the computer display, and a support plate connected with the bottom of the support column, wherein the support column comprises an inner tube and an outer tube installed on the inner tube in a sleeving manner, a bottom cover sleeves the outer tube, a vertical column is fixed on the bottom cover, and a bevel gear I sleeves the top of the vertical column; and a screw rod is connected to the bottom of the inner tube, and the bottom of the screw rod is connected with the bevel gear I. The computer display capable of manually lifting further comprises a hand-cranking device, wherein the hand-cranking device comprises a bevel gear II and a handle cross rod connected with a gear shaft II of the bevel gear II, the bevel gear II is engaged with the bevel gear I, a side hole is formed in the lower end of the outer tube, the handle cross rod penetrates out from the side hole, and a handle is connected to the penetrating end of the handle cross rod. According to the computer display capable of manually lifting, which is disclosed by the invention, transmission connection between the handle cross rod and the screw rod is realized through the engaged bevel gears, rotation of the handle cross rod drives the vertical screw rod to rotate, and the rotation of the screw rod drives the inner tube to carry out linear reciprocating motion, thus the height of the support column is variable, and the problem that the height of the computer display cannot be adjusted is solved.

Owner:CHENGDU YANXINGGUO TECH CO LTD

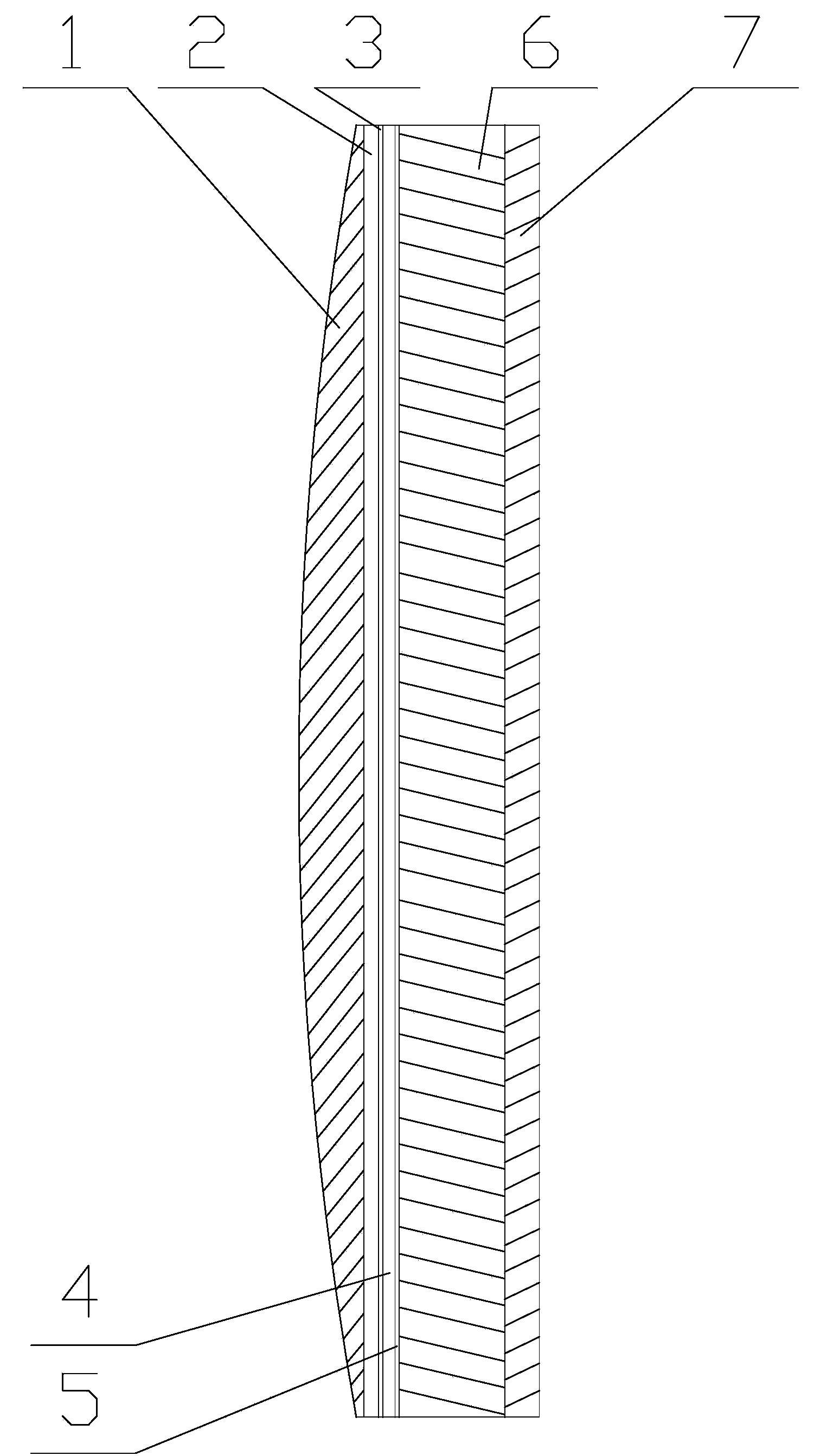

An environmental friendly energy-saving recycled building template and a manufacturing method thereof

The invention relates to an environmental friendly energy-saving recycled building template and a manufacturing method thereof. The building template and the method are characterized in that the building template is prepared from following components: 80-90% of powder of waste PPR, PE and PVC with the particle fineness of the powder being 60-80 meshes, 10-20% of active calcium carbonate powder with the particle fineness being 1500-2000 meshes, and 5-8% of various-color foaming adjusting agents. Compared with the prior art, building wastes are fully utilized, and the produced building template has advantages of environment protection, energy conservation, cyclic regeneration, ageing resistance, waterproofness, moisture-proofness, no deformation, no cracking, no mildew, light and convenient conveying, capability of being economical, and the like.

Owner:威海和光新材料科技有限公司

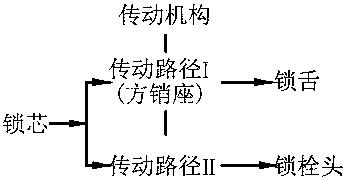

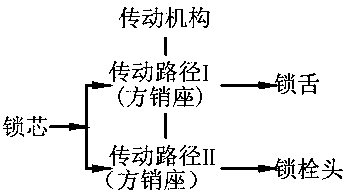

Lock cylinder controlled self-locking anti-theft lock

ActiveCN106760957AOpen and close controlAvoid open and closed problemsNon-mechanical controlsLocking mechanismElectrical and Electronics engineering

The invention relates to a lock cylinder controlled self-locking anti-theft lock which comprises a locking housing, a lock cylinder and a square pin seat matched with a square pin. The lock cylinder and the square pin seat are arranged in the locking housing. The lock cylinder controlled self-locking anti-theft lock further comprises a self-locking mechanism, a lock cylinder shifting mechanism and a linkage part connected with the self-locking mechanism and the lock cylinder shifting mechanism, the self-locking mechanism is matched with the square pin seat in a one-way rotation-limiting mode, and the square pin seat rotates during locking limiting. The lock cylinder shifting mechanism with the lock cylinder transfers a rotation state of lock cylinder unlocking to the self-locking mechanism through the linkage part, and accordingly the self-locking state between the self-locking mechanism and the square pin seat is relieved. The existing problem that the anti-theft lock can be unlocked by directly turning the square pin is solved.

Owner:重庆美心蒙迪门业制造有限公司

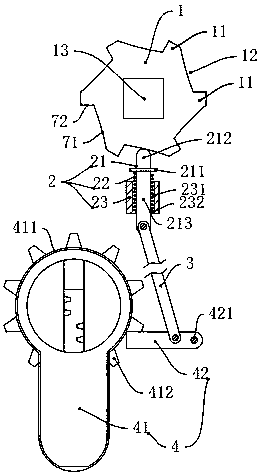

Fan and control method thereof

The invention discloses a fan and a control method thereof. The fan comprises a frame and at least two fan blade assemblies, wherein the fan blade assemblies are arranged in the frame; the frame is provided with air outlets corresponding to the fan blade assemblies; and at least one of the fan blade assemblies is provided with an angle adjusting device adjusting the angle of the fan blade assembly. By adjustment of one of the fan blade assemblies or two of the fan blade assemblies or all the fan blade assemblies, the size or position of the air supply area of the whole fan can be achieved, andthe flexibility and variability of the adjustment are high.

Owner:GREE ELECTRIC APPLIANCES INC

Light emitting structure with stereoscopic display effect

InactiveCN103985326ASimplify the manufacturing processReduce scrap rateIlluminated signsOptoelectronicsLight guide

The invention relates to the field of display equipment, in particular to a light emitting structure with stereoscopic display effect. The light emitting structure comprises a base material piece, a transparent layer is mounted on the base material piece, and a diffusion sheet, a light guide sheet and a reflector sheet are mounted under the base material layer in sequence; the transparent layer is a lens; the base material piece is a transparent film; the light guide sheet is provided with a plurality of light guide points; the base material layer comprises a transparent base layer, the base layer is formed with a mark layer through vacuum splattering and printing, the mark layer is composed of at least one stereoscopic mark, and the stereoscopic mark is uneven and has height difference. The light emitting structure has good stereoscopic effect, is capable of better embodying the appearance decoration effect and is beautiful, the pattern is clear, the variability is strong, and the light resistance and moisture resistance are good; the manufacturing process is simpler, and the rejection rate is lowered; there is only one mark layer, the bubbling phenomenon is avoided, and the overall appearance effect is good.

Owner:URC ELECTRONIC TECHNOLOGY (KUNSHAN) CO LTD

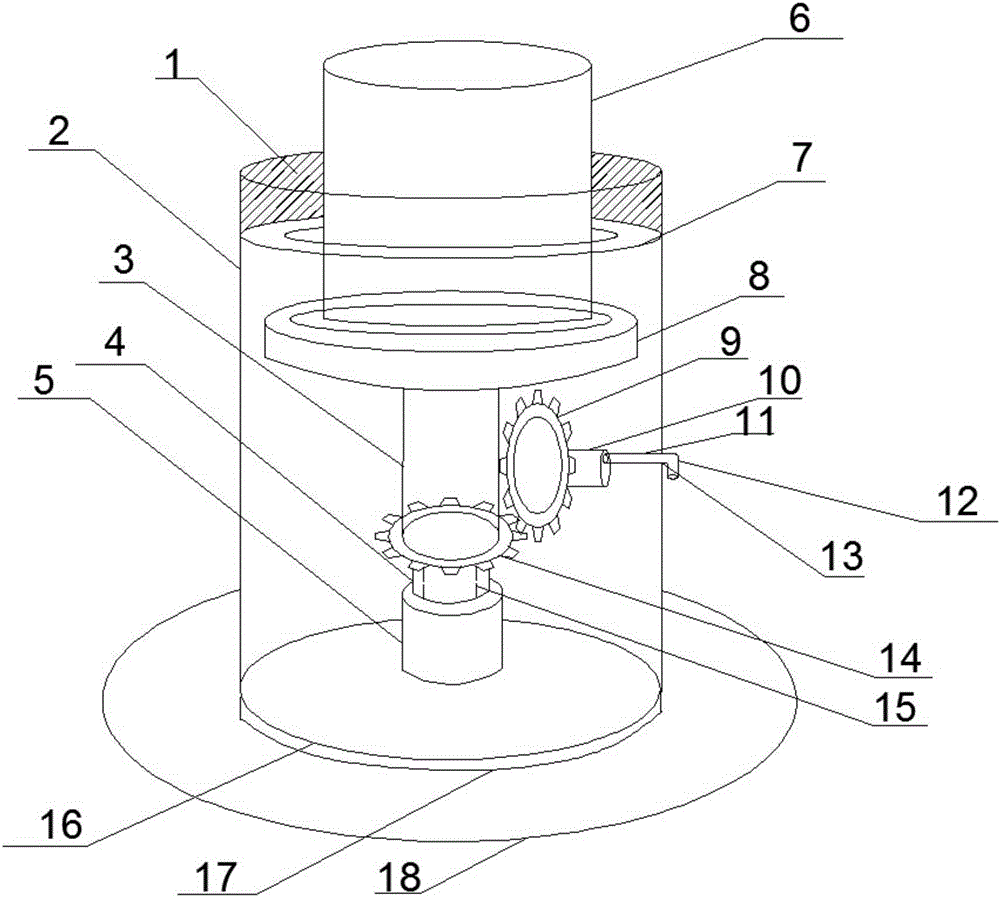

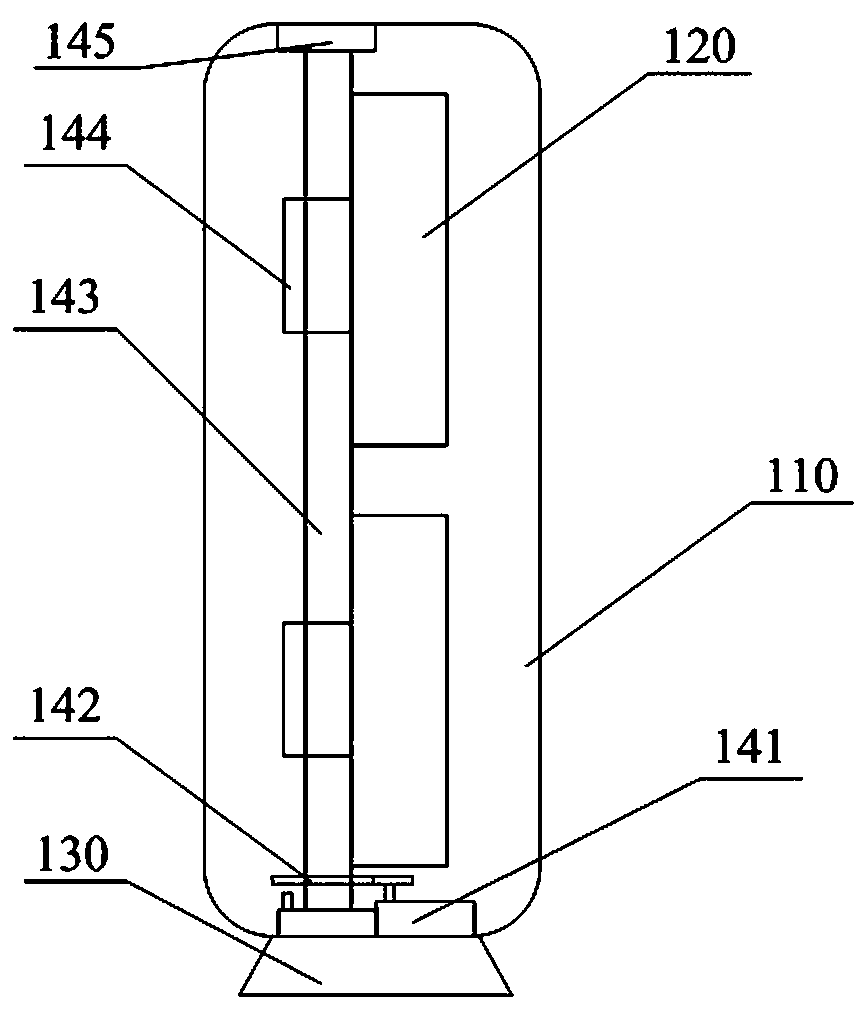

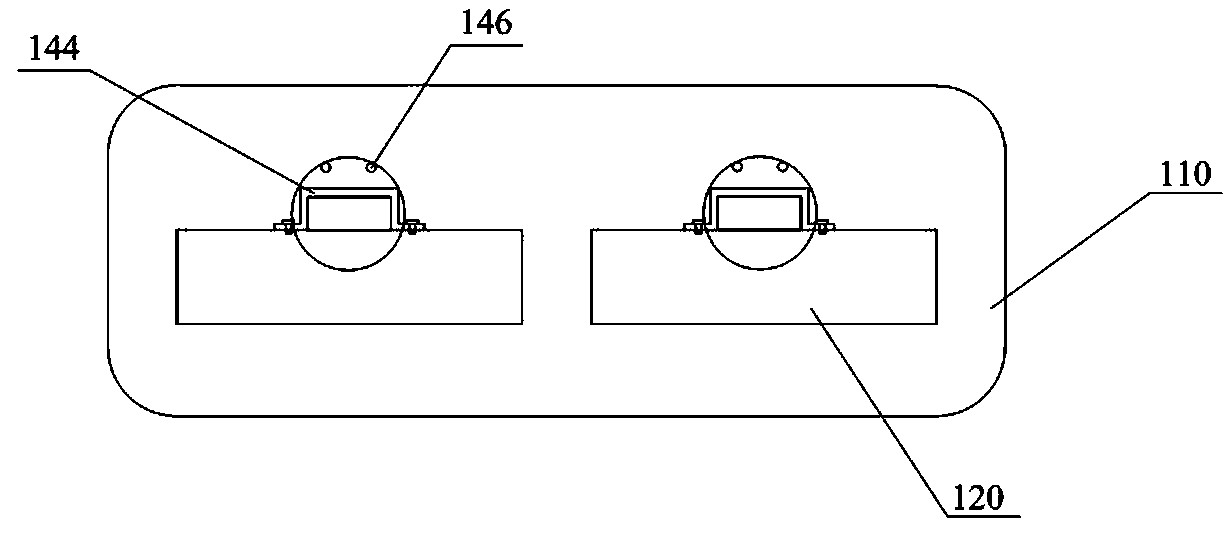

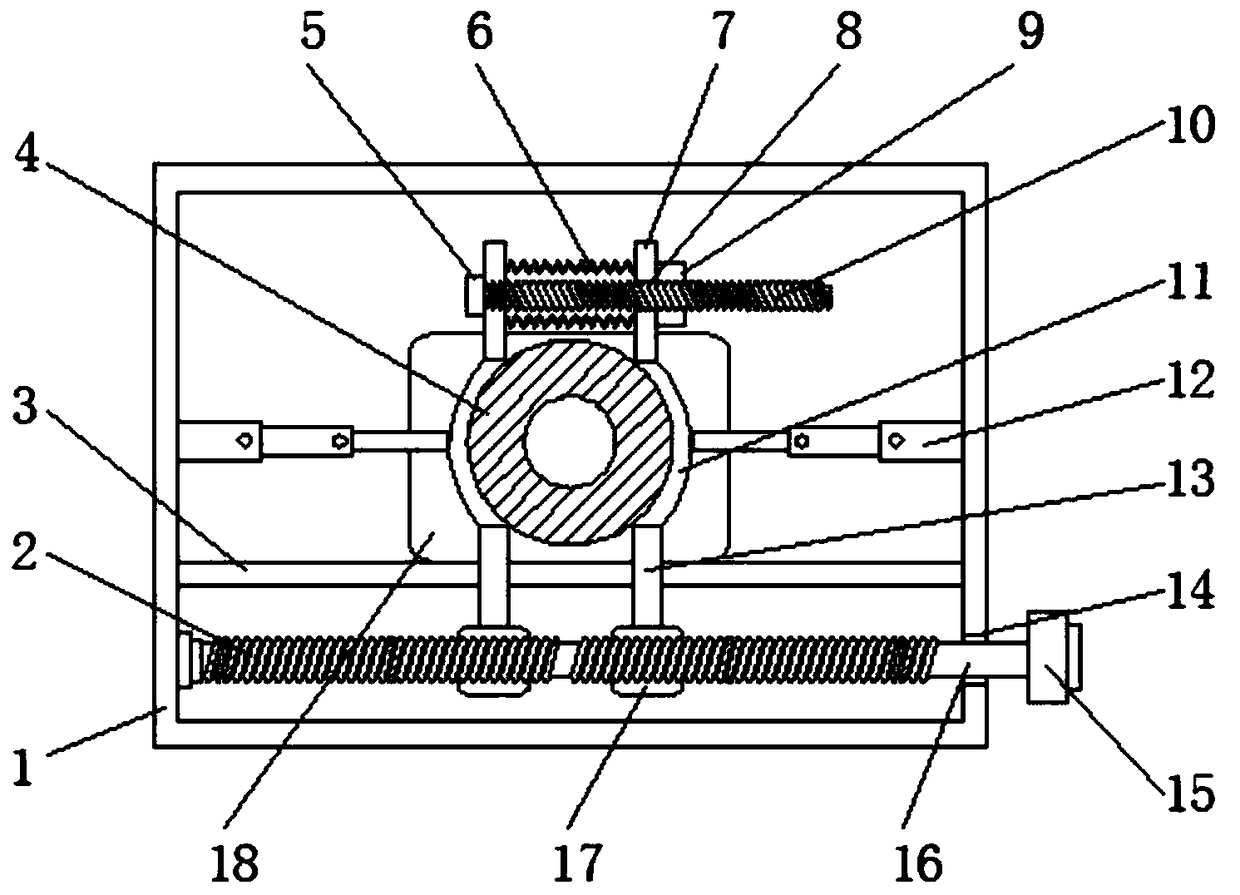

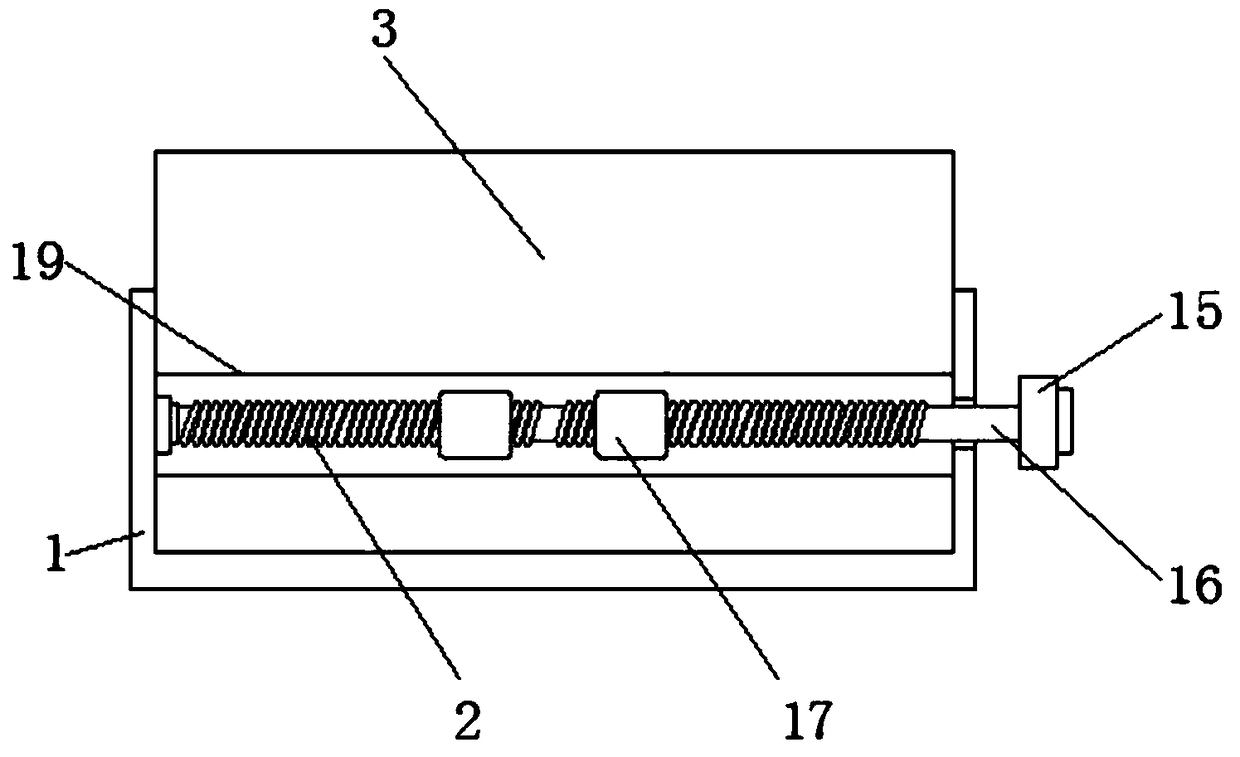

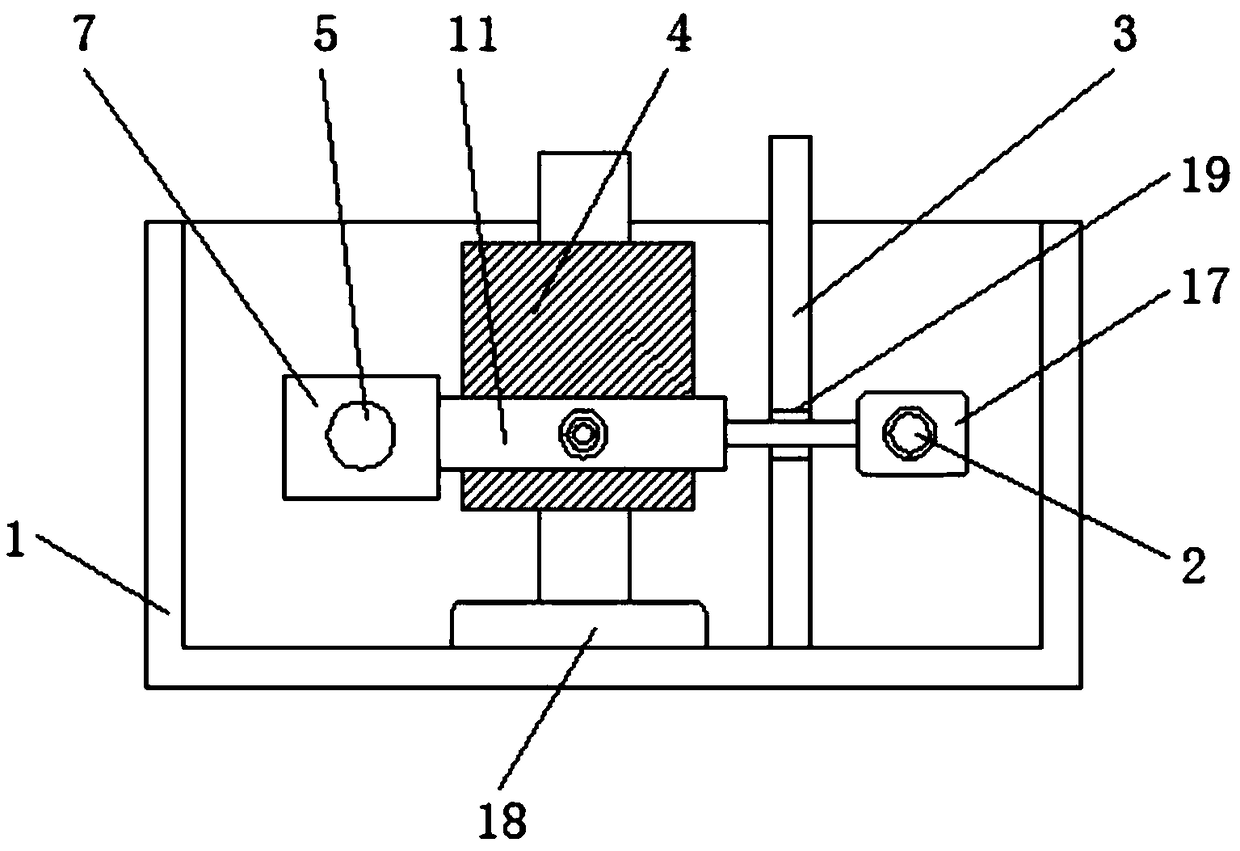

Convenient-to-fix auxiliary device for motor rotor processing

InactiveCN109462316AStrong fixed effectHighly variableManufacturing stator/rotor bodiesMiddle lineEngineering

The invention discloses a convenient-to-fix auxiliary device structure for motor rotor processing. The convenient-to-fix auxiliary device comprises a semi-closed box, wherein a two-way threaded rod ishorizontally arranged inside the semi-closed box; the two-way threaded rod is located at the middle line of a longitudinal side wall of the semi-closed box; a connecting rod is horizontally welded atone end of the two-way threaded rod; the other end of the two-way threaded rod is rotationally connected with an inner side wall of the semi-closed box through a bearing; and the two-way threaded rodis sleeved with two thread bushings. Firstly, double fixing assemblies are arranged in the device, so that a good fixing effect is achieved, and a rotor can be supported. Secondly, the distance between two clamping plates can be adjusted manually, which is suitable for fixing rotors of different sizes, thereby achieving high variability. Finally, the assemblies used for adjusting the distance between the clamping plates are isolated, so that the situation that the assemblies cannot be used normally when debris generated during drilling enters the assemblies is avoided.

Owner:武汉安兰斯电气科技有限公司

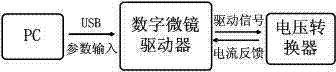

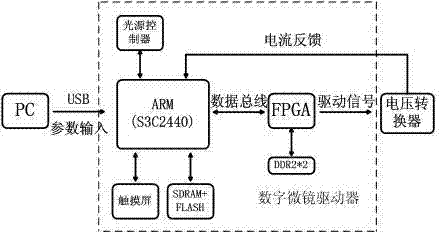

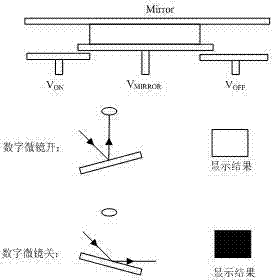

Driving waveform generator for digital micromirror devices

ActiveCN103117733AEasy to operateUniversalElectric pulse generator circuitsOptical elementsVoltage converterMan machine

The invention discloses a driving waveform generator for digital micromirror devices. The driving waveform generator comprises a PC (personal computer), a digital micromirror driver and a voltage converter. The PC communicates with the digital micromirror driver for parameter editing and inputting through USB (universal serial bus). A touch screen is used as a man-machine interface to make control and operation convenient and simple. An ARM (advanced RISC machine) transmits waveform parameters to an FPGA to allow for formation of original driving waveform (field programmable gate array) by 32-bit parallel communications. High level of drive voltage can be raised to 15V-200V by boosting of the voltage converter, and the adjustment is convenient and simple. Load current is fed back to the ARM to allow for automatic adjustment. By the use of the driving waveform generator, the problem that the existing digital micromirror device driving waveform generation circuit is single is solved. Power can be adjusted to obtain variable waveforms and adjustable voltage by changing parameters without changing the driving circuit, and driving waveforms of digital micromirrors are automatically adjusted.

Owner:EAST CHINA NORMAL UNIV

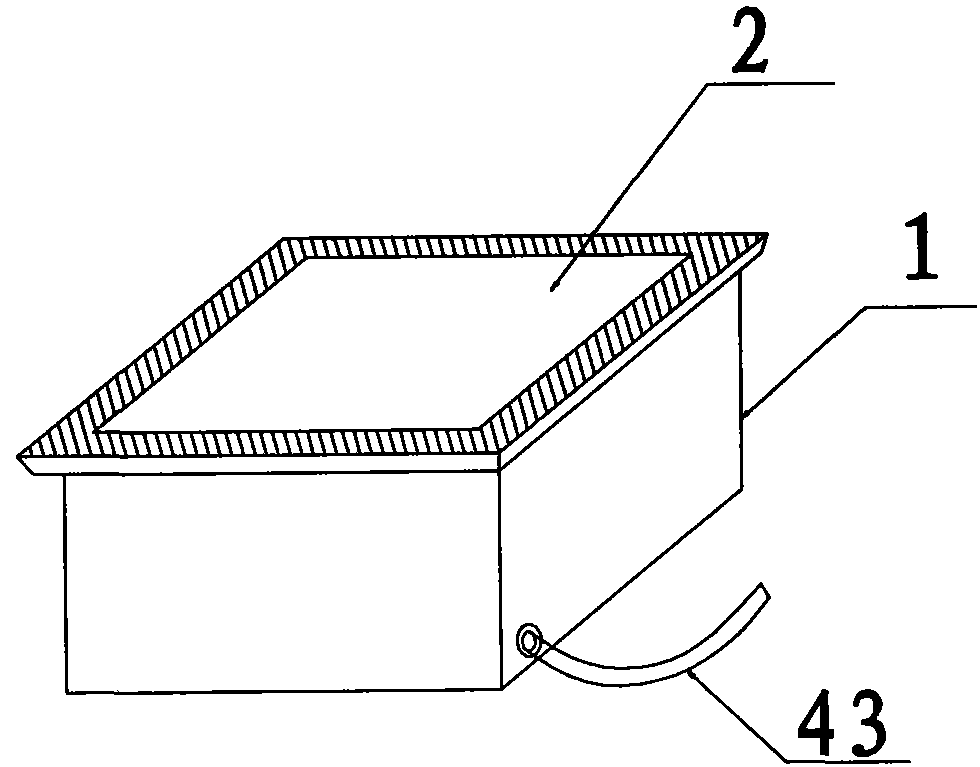

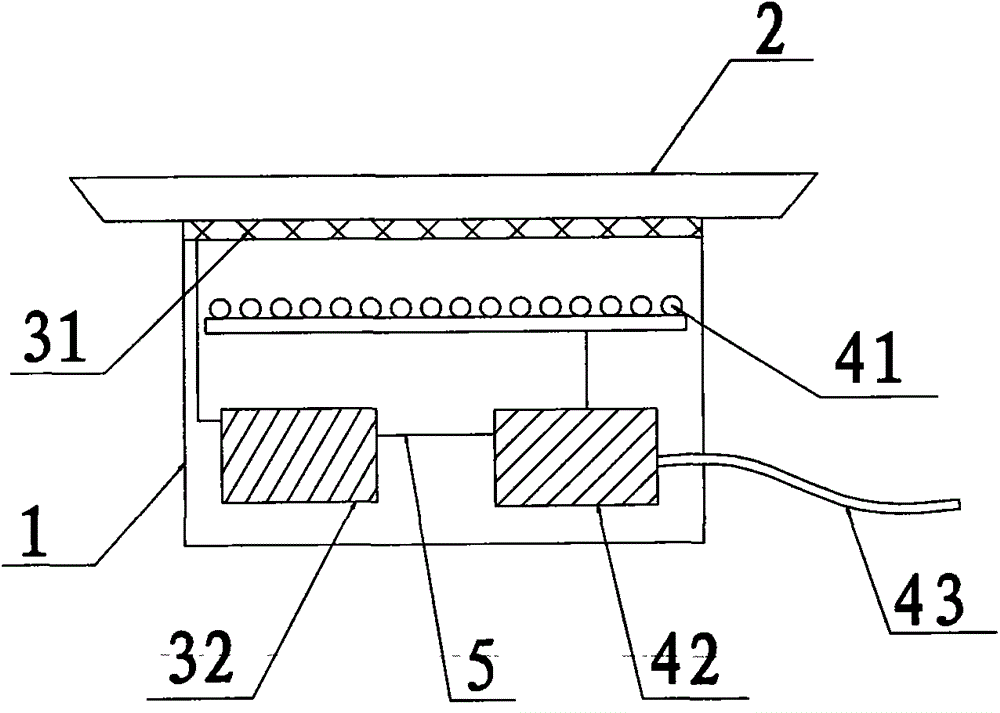

LED floor tile lamp

InactiveCN104456330ASimple structureHighly variableLighting applicationsMechanical apparatusElectricityEngineering

The invention discloses an LED floor tile lamp. The LED floor tile lamp comprises a shell, a piece of tempered glass which is located on the top of the shell, and a pressure sensing device and a light emitting device which are located in the shell. The pressure sensing device is electrically connected with the light emitting device. The LED floor tile lamp is simple in structure, fashionable and novel; low-voltage safe electricity is used, and therefore the LED floor tile lamp is quite safe and convenient to install and maintain.

Owner:赵立平

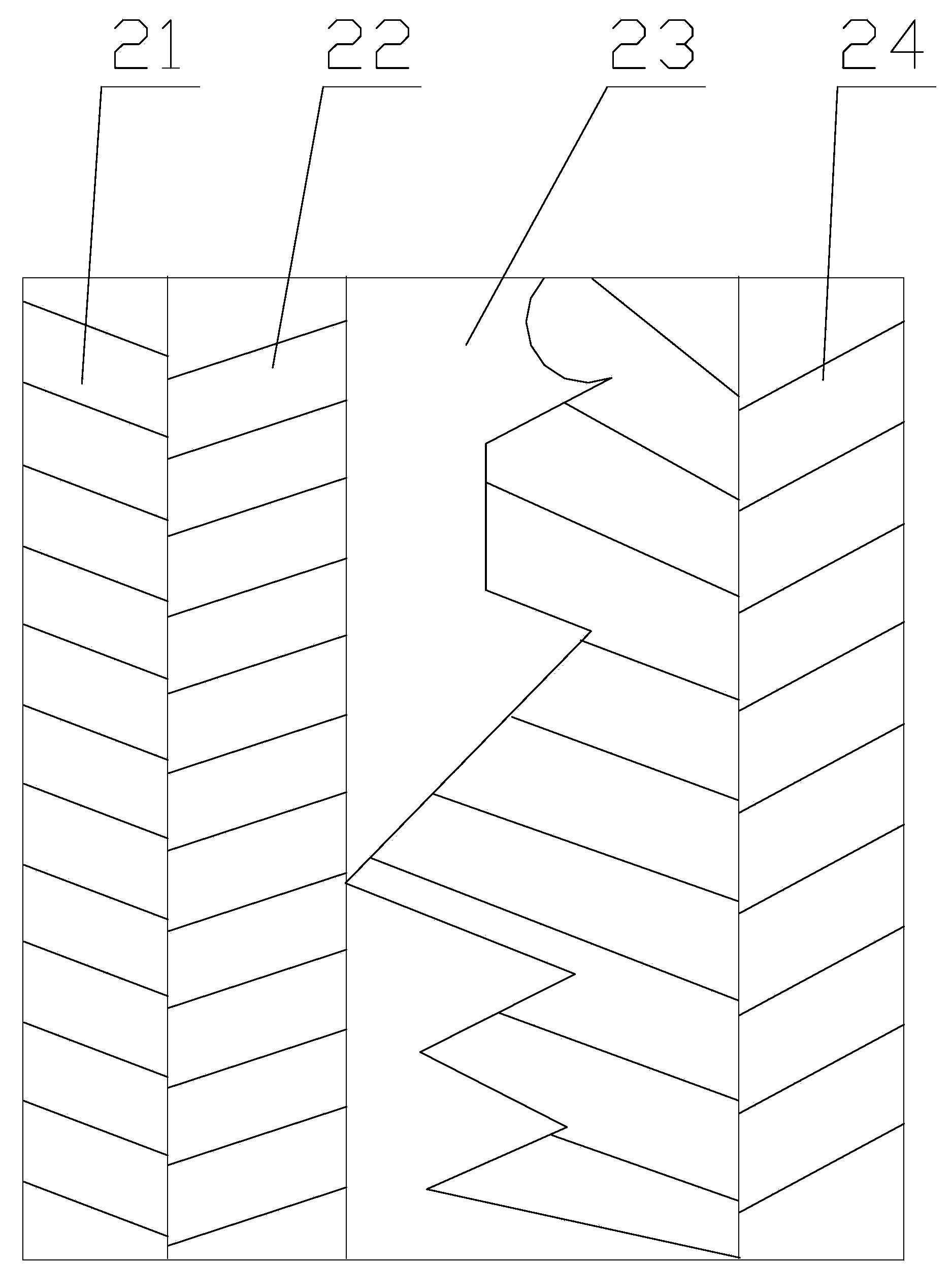

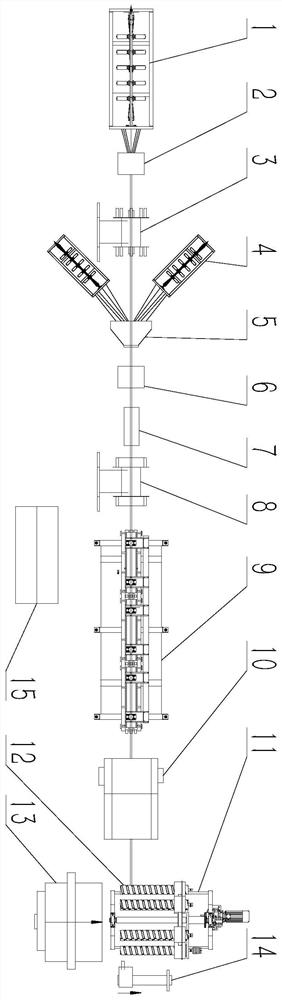

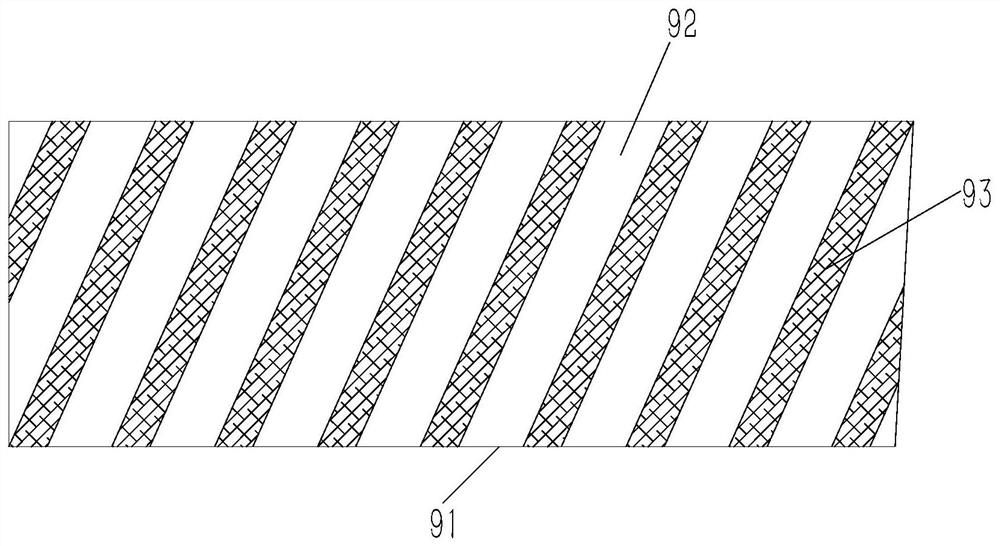

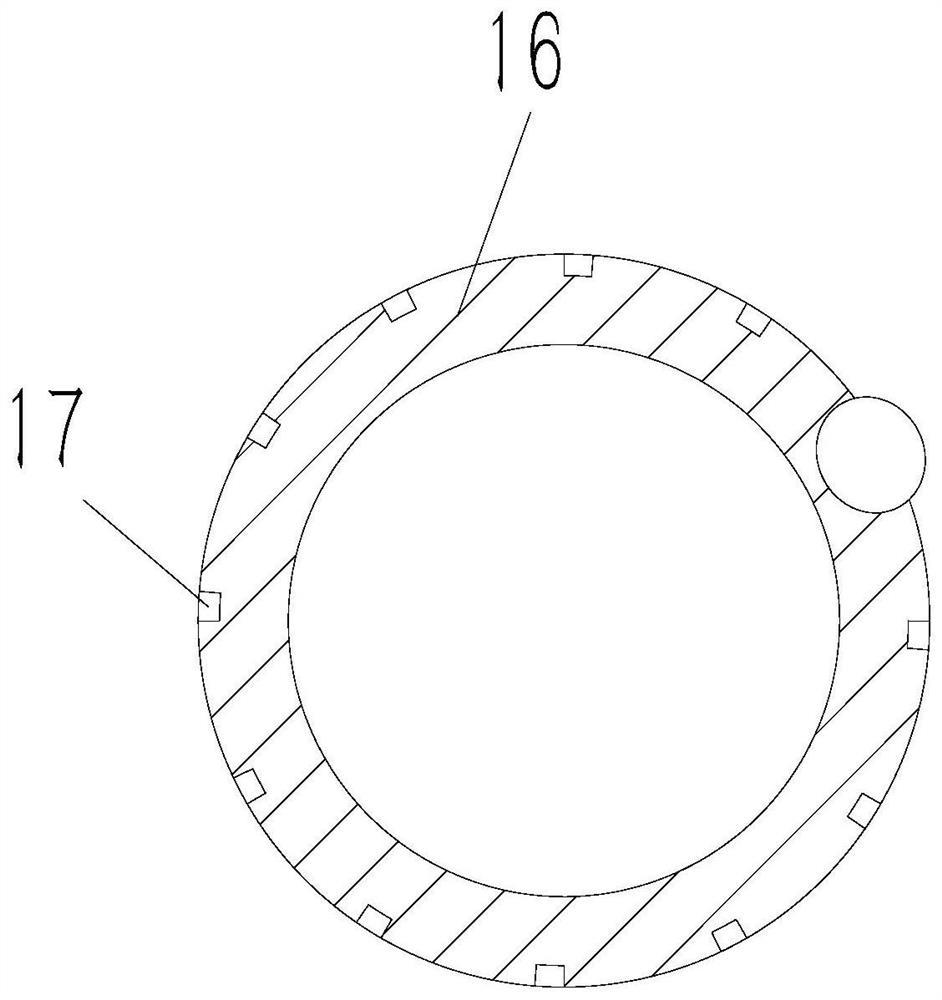

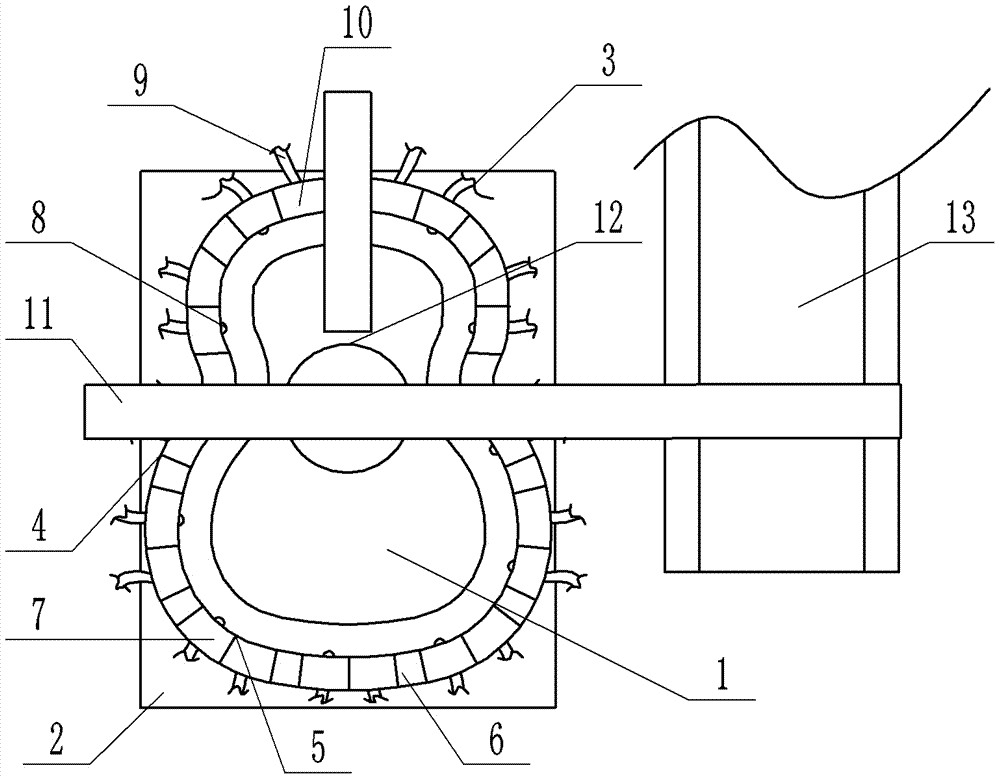

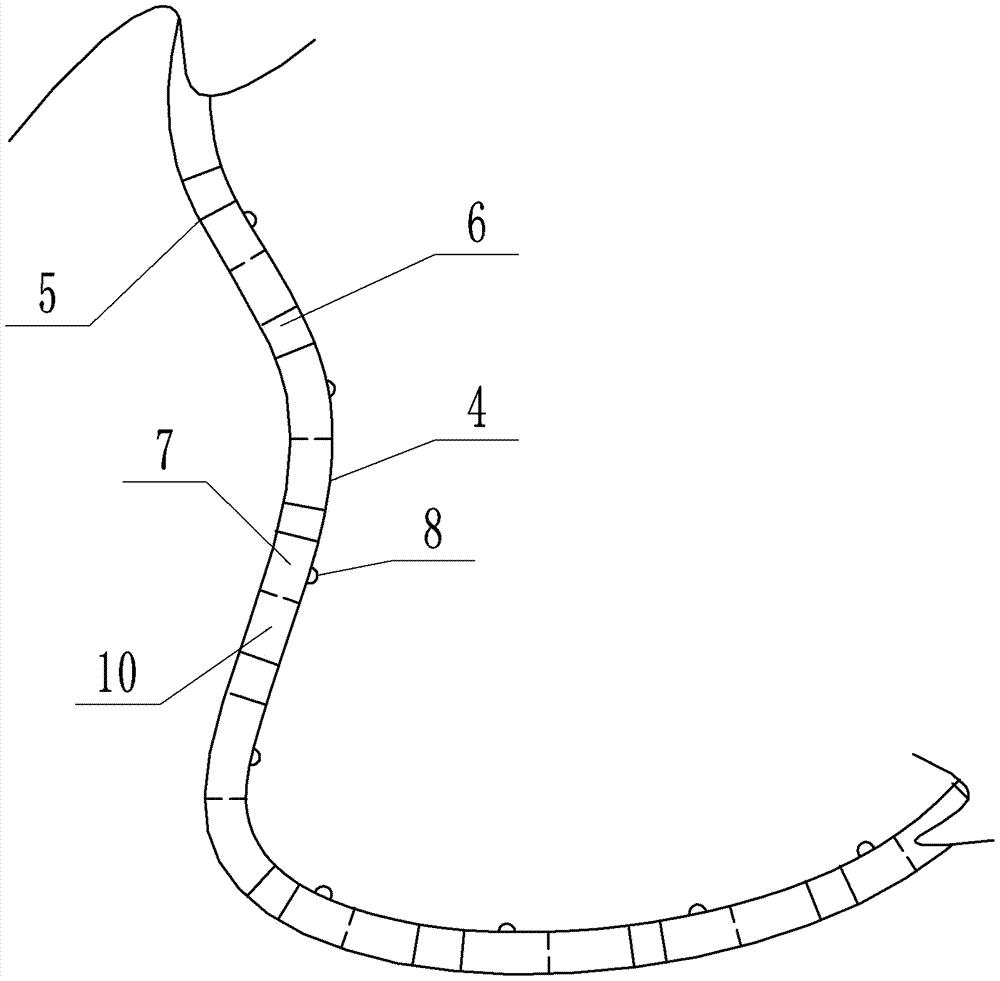

Manufacturing method and production line of continuous fiber composite material spring and spring

PendingCN113320125AControl resin contentPrevent burstDomestic articlesCoatingsFiber bundleFibrous composites

The invention discloses a production line of a continuous fiber composite material spring. A layer of thermoplastic film is wound outside a to-be-cured continuous fiber bundle before the to-be-cured continuous fiber bundle is cured and formed by a spring forming and curing mold, and the continuous fiber bundle wound with the thermoplastic film is fed into the spring forming and curing mold after being subjected to circumferential spiral extrusion. In the process of winding the thermoplastic film around the to-be-cured continuous fiber bundle, secondary compression and fastening can be generated on the to-be-cured continuous fiber bundle, gaps and bubbles of all fibers among the to-be-cured continuous fiber bundle are reduced, and the density of the cured continuous fiber spring is improved; and meanwhile, after the fiber bundle wound with the thermoplastic film is spirally extruded in the circumferential direction, the to-be-cured continuous fiber bundle is further extruded, the density of the to-be-cured continuous fiber bundle is further improved, at the moment, the thermoplastic film wrapping the to-be-cured fiber bundle can prevent the to-be-cured fiber bundle from bursting and scattering due to stress, and the appearance quality and the molded dimension precision of products are improved.

Owner:南京诺尔泰复合材料设备制造有限公司

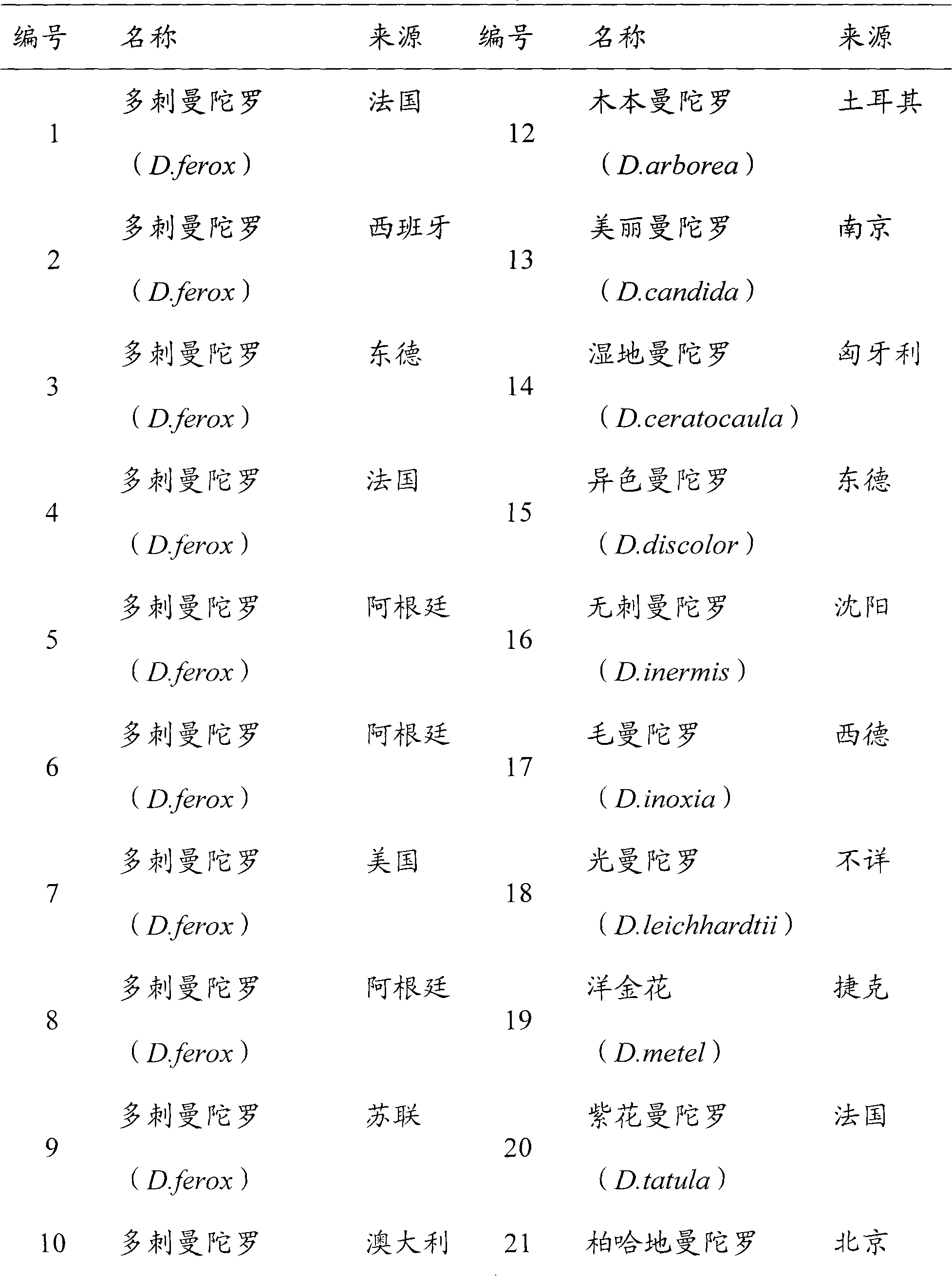

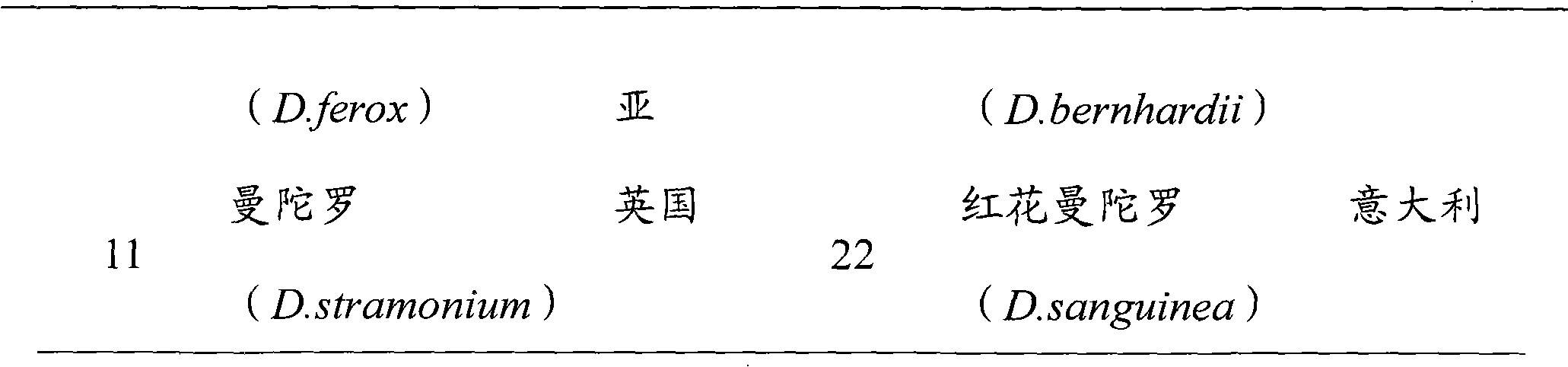

Nucleic acid composition for detecting Datura ferox and application thereof

ActiveCN101988126AEasy to sortHighly variableMicrobiological testing/measurementFluorescence/phosphorescenceBiotechnologyQuarantine

The invention provides a nucleic acid composition for detecting Datura ferox, which comprises a nucleic acid primer F shown as SEQ ID No. 1, a nucleic acid primer R shown as SEQ ID No. 2 and a nucleic acid molecular probe P shown as SEQ ID No. 3 or a nucleic acid chain which is fully complementary with the nucleic acid primer F, the nucleic acid primer R and the nucleic acid molecular probe P. In the invention, by adopting a real-time fluorescent polymerase chain reaction (PCR) detection technology, the nucleic acid composition of the invention can complete detection within half of a working day, thus greatly shortening detection time and obviously improving detection sensitivity. The nucleic acid composition can be applied to the fields such as port inspection and quarantine, agricultural production, plant protection and the like, thus achieving the purpose of rapid and accurate detection and identification.

Owner:中华人民共和国上海海关

Guitar side edge painting device

ActiveCN107127070AEffective regulationHighly variablePretreated surfacesLiquid spraying apparatusEngineeringElectromagnet

The invention discloses a guitar side edge painting device. The device comprises a frame, a paint box and a paint pump connected with the paint box. The device is characterized by further comprising a baseplate arranged on the frame, multiple paint pipes and a deformable painting unit; the painting unit comprises multiple arc painting blocks, and multiple detachable connecting pieces for pairwise connecting the arc painting blocks; paint cavities are formed in the arc painting blocks; one side surfaces of the paint cavities are connected with the paint pump through the paint pipes, and painting nozzles are arranged on the other side surfaces; iron blocks are arranged at the bottoms of the arc painting blocks; and electromagnets are arranged on the baseplate. The device can effectively adjust the painting unit according to different sizes and different shapes of different guitars, is high in variability and flexibility, is wide in application range, sprays paint in multiple directions by multiple angles without generating the phenomena of nonuniform painting and no corner spraying, and is excellent in painting effect and high in efficiency.

Owner:贵州融合音源乐器有限公司

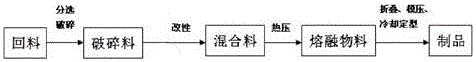

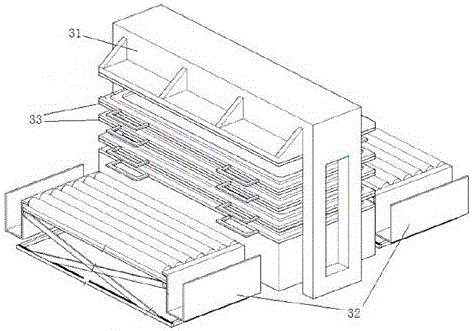

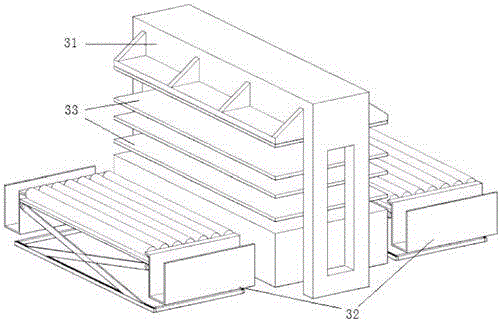

Preparation method of automotive interior part leftover material molded part

InactiveCN106079163AWide range of usesSimple processPlastic recyclingMechanical material recoveryPollutionMaterials science

The invention relates to a preparation method of an automotive interior part leftover material molded part. The method comprises the following steps: (1) crushing reclaimed automotive interior part leftover materials; and (2) hot-pressing, melting and cooling the crushed materials to obtain the molded product. According to the method, the molded product is prepared from the automotive interior part leftover materials, the raw materials are friendly to environment, low in cost and free of secondary pollution, and the molded product is light in mass and high in strength, can be recycled, and has a wide industrial application range and high economic and social values.

Owner:NINGBO HUAYE MATERIAL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com