Laser edge scanning device capable of machining glass chip of any shape

A glass chip and arbitrary shape technology, which is applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of affecting the processing quality, poor edge sweeping accuracy, and inability to accurately control the edge sweeping parallelism, achieving improved accuracy, Strong flexibility and variability, improved edge sweeping accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

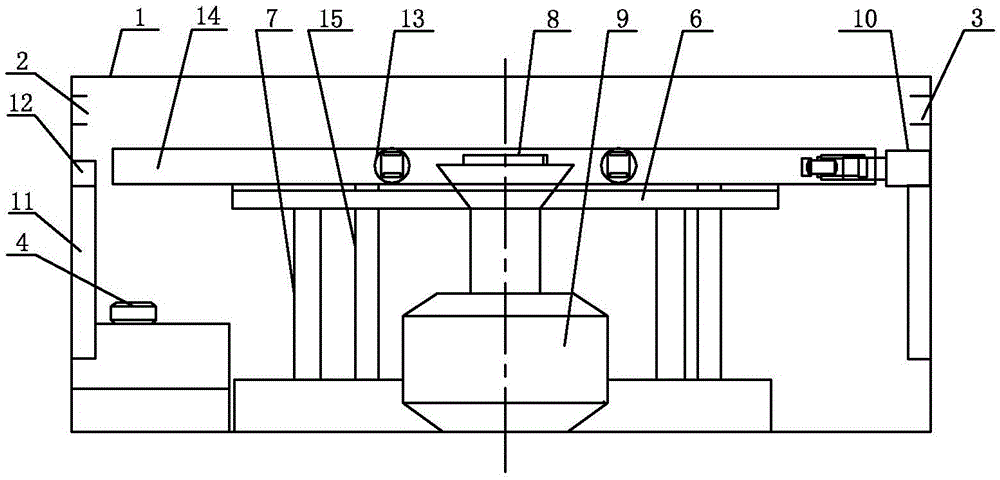

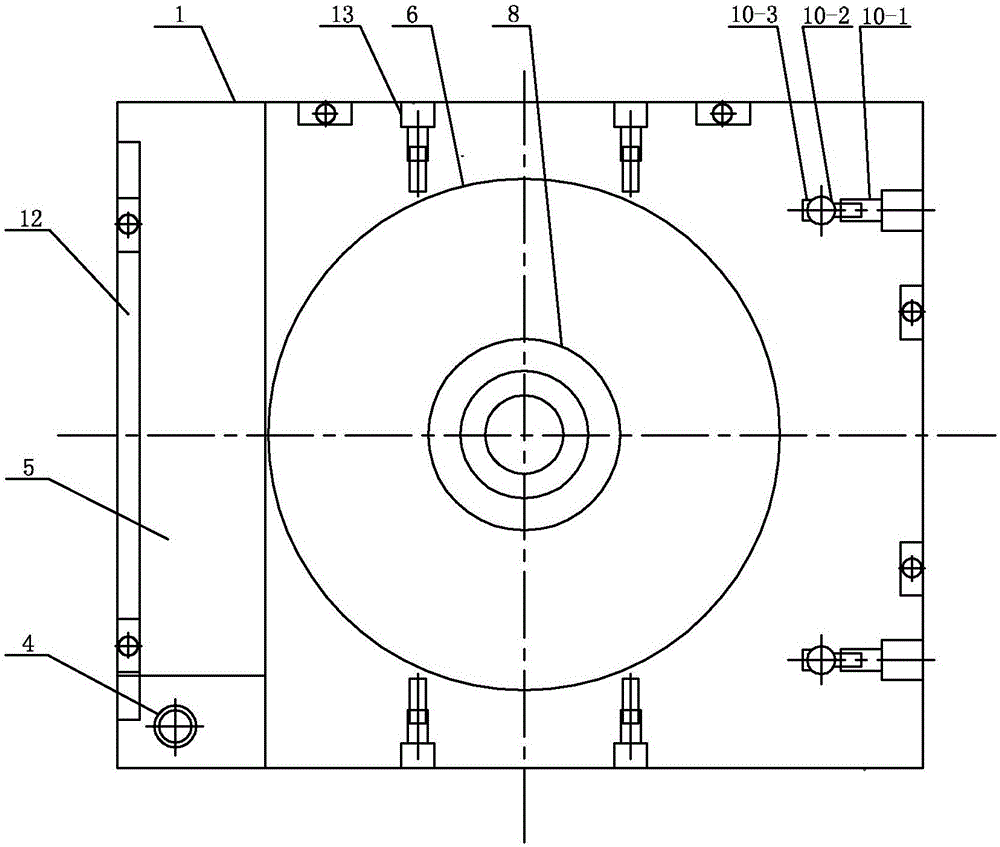

[0013] Specific implementation mode one: combine figure 1 and figure 2 Describe this embodiment mode, a laser edge sweeping device that can process glass chips of any shape described in this embodiment mode, it includes a housing 1, a laser 4, a laser track 5, an air floating platform 6 and at least one pillar 7, the housing 1 is Rectangular box body, the air floating platform 6 is arranged in the middle of the shell 1 through at least one pillar 7, the left side wall of the shell 1 is provided with a feed port 2, and the right side wall of the shell 1 is provided with a discharge port 3, The feed port 2 is set opposite to the discharge port 3, and the laser 4 is set in the laser track 5. A laser edge sweeping device capable of processing glass chips of any shape also includes a vacuum chuck 8, a rotatable support 9, a positioning device, two Universal pusher 10 and two liftable brackets 11, the air bearing platform 6 is circular, the vacuum suction cup 8 is arranged in the ...

specific Embodiment approach 2

[0015] Specific implementation mode two: combination figure 1 and figure 2 Describe this embodiment, the positioning device described in this embodiment includes a clip guide rail 14, at least one clip guide rail support column 15 and a plurality of clips 13, the clip guide rail 14 is arranged above the air bearing platform 6, and at least one clip guide rail support column 15 The upper end is evenly arranged on the lower surface of the clip guide rail 14, the lower end of at least one clip guide rail support column 15 is evenly arranged on the upper surface of the bottom end surface of the housing 1, and a plurality of clips 13 are movably arranged in the clip guide rail 14. With such arrangement, the clamp 13 can move telescopically to position glass chips at different angles and then clamp them. Other compositions and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0016] Specific implementation mode three: combination figure 2 To describe this embodiment, the number of clips 13 in this embodiment is four. In this way, the glass chip is quadrilateral, and the four clips 13 respectively fix the four sides of the glass chip, so that the positioning of the glass chip is more precise and firm. Other compositions and connections are the same as those in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com