Ship unberthing and berthing device

A technology for ships and berthing, applied in shipping equipment, climate change adaptation, etc., can solve the problems of poor buffering effect, single function and small scope of application of anti-collision and shock absorption devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

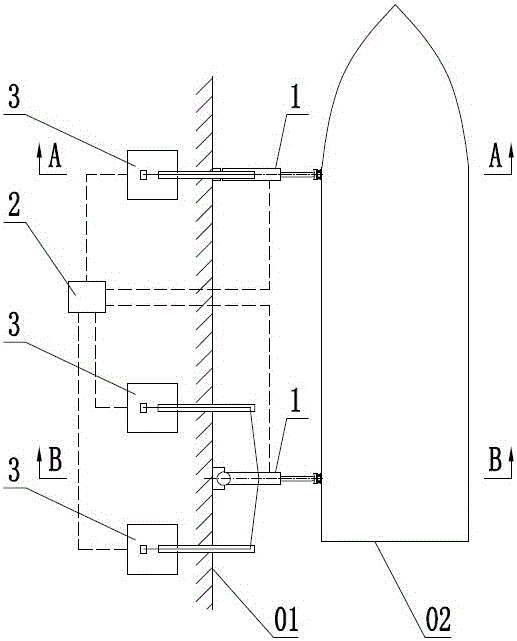

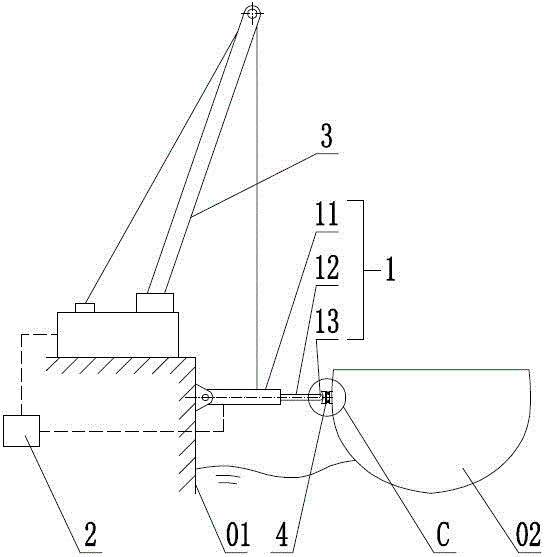

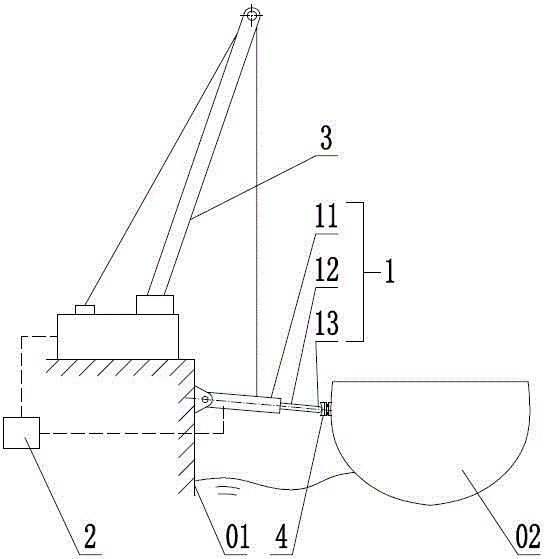

[0026] In the example, such as figure 1 , figure 2 , image 3 , Figure 4 As shown, a ship berthing device includes at least two hydraulic cylinders 1 and an operation center 2 that controls the action of the hydraulic cylinders 1. The hydraulic cylinder 1 includes a cylinder body 11 and a piston rod 12. The cylinder body 11 The tail of the tail is hinged on the wharf 01, the cylinder 11 can rotate in the vertical plane, the end of the piston rod 12 is used to push the ship 02, and the height of the end of the piston rod 12 is lower than or equal to The height of the tail of the cylinder body 11 , the wharf 01 is provided with a crane 3 that drives the cylinder body 11 to rotate, and the crane 3 is controlled by the operation center 2 . In this embodiment, the contraction of the piston rod 12 of the hydraulic cylinder 1 completes the anti-collision...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com