Driving waveform generator for digital micromirror devices

A digital micromirror device and digital micromirror technology are applied in electric pulse generator circuits, instruments, optical components, etc., which can solve problems such as energy-consuming, wasting money, and non-existence, and achieve convenient operation, strong driving ability, and reliable operation. strong denaturing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

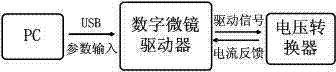

[0030] refer to figure 1 , the present invention is made up of PC, digital micromirror driver, voltage converter three parts. The PC communicates with the digital micromirror driver through USB, and can realize waveform editing, parameter setting and modification on the PC; the original driving signal generated by the digital micromirror driver is transmitted to the voltage converter, and the voltage converter converts the load current Feedback to the digital micromirror driver; the voltage of the voltage converter is directly supplied by the external power supply, and the size can be adjusted by the power supply, and the adjustment range is 30V-60V.

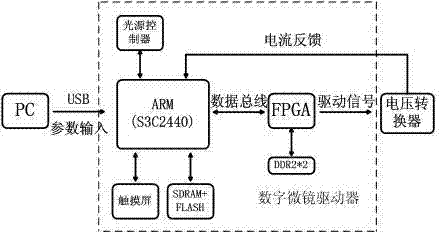

[0031] refer to figure 2 , the digital micromirror driver of the present invention includes ARM (microprocessor, model S3C2440), FPGA (programmable logic device, model EP3C16F484C6N), TFT touch screen, SDRAM (dynamic random access memory), FLASH, DDR2 (dynamic random access memory) and light source controller.

[0032] ARM i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com