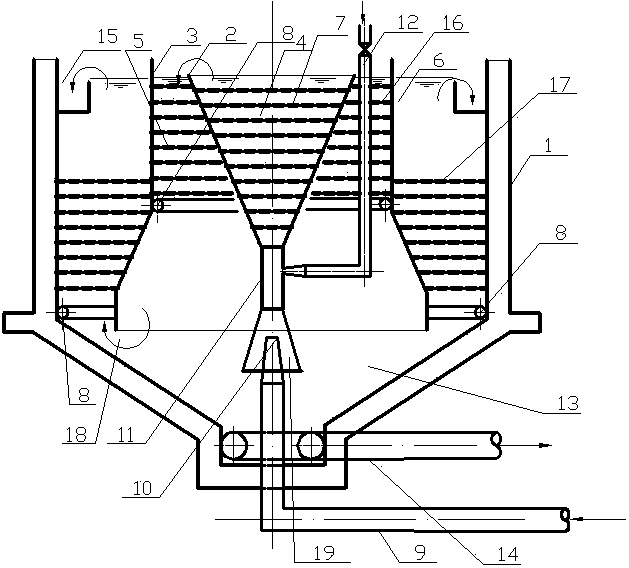

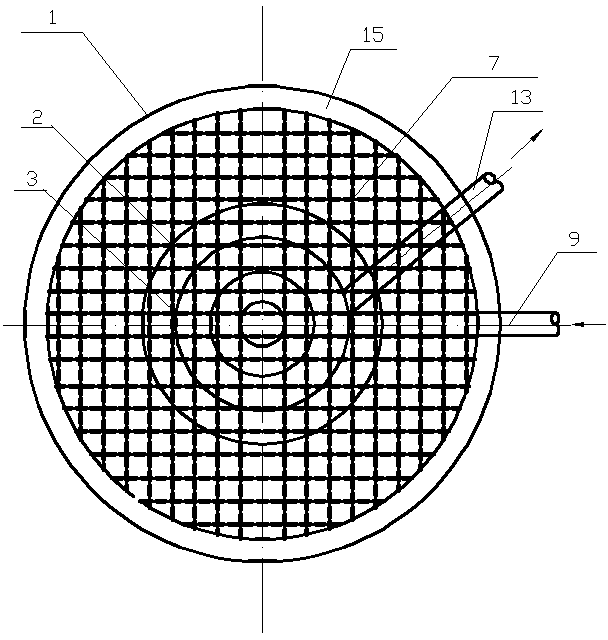

Aerobic granular sludge integrated sewage treating device and method

A technology for aerobic granular sludge and sewage treatment, applied in water/sludge/sewage treatment, water/sewage treatment equipment, water/sewage treatment, etc. , the problem of high operating energy consumption, to achieve the effect of solving the interference of denitrification function, improving the water flow environment and low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Method embodiment 1, an aerobic granular sludge integrated sewage treatment method, including activated sludge inoculation before operation, cultivation of dominant bacteria and continuous operation treatment;

[0047] First, the inoculation of activated sludge and the cultivation of dominant bacteria before operation

[0048] Before the continuous operation of the biochemical device, the activated sludge inoculation and the cultivation of dominant strains were completed, and ammonia oxidizing bacteria and denitrifying phosphorus accumulating bacteria (DPAO) were used for double sludge short-cut nitrification s ) is the dominant strain, and the aeration volume of the reactor is controlled at 0.21m during the cultivation period 3 / h; use high-load inoculation cultivation, suffocate for 36 hours, then continuously enter water and aerate continuously. When the MLSS in the pool is close to about 3.5g / L and the sludge index SVI is about 90, the sedimentation ratio SV is 28%....

Embodiment 2

[0051] Method embodiment 2, the first, the cultivation of activated sludge inoculation and dominant bacterial species before operation

[0052] Before the continuous operation of the biochemical device, the activated sludge inoculation and the cultivation of dominant strains were completed, and ammonia oxidizing bacteria and denitrifying phosphorus accumulating bacteria (DPAO) were used for double sludge short-cut nitrification s ) is the dominant strain, and the aeration volume of the reactor is controlled at 0.21m during the cultivation period 3 / h; use high-load inoculation cultivation, suffocate for 48 hours, then continuously enter water and aerate continuously. When the MLSS in the pool is close to about 4.0g / L and the sludge index SVI is about 80, the sedimentation ratio SV is 26%. That is, the cultivation is successful;

[0053] Second, the continuous operation process is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com