Optical fiber display screen and manufacturing method thereof

A technology for display screens and manufacturing methods, applied in the direction of bundles of optical fibers, optics, optical components, etc., can solve the problems of high energy consumption, high cost, and potential costs, and achieve low energy consumption, long service life, and strong variability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with accompanying drawing:

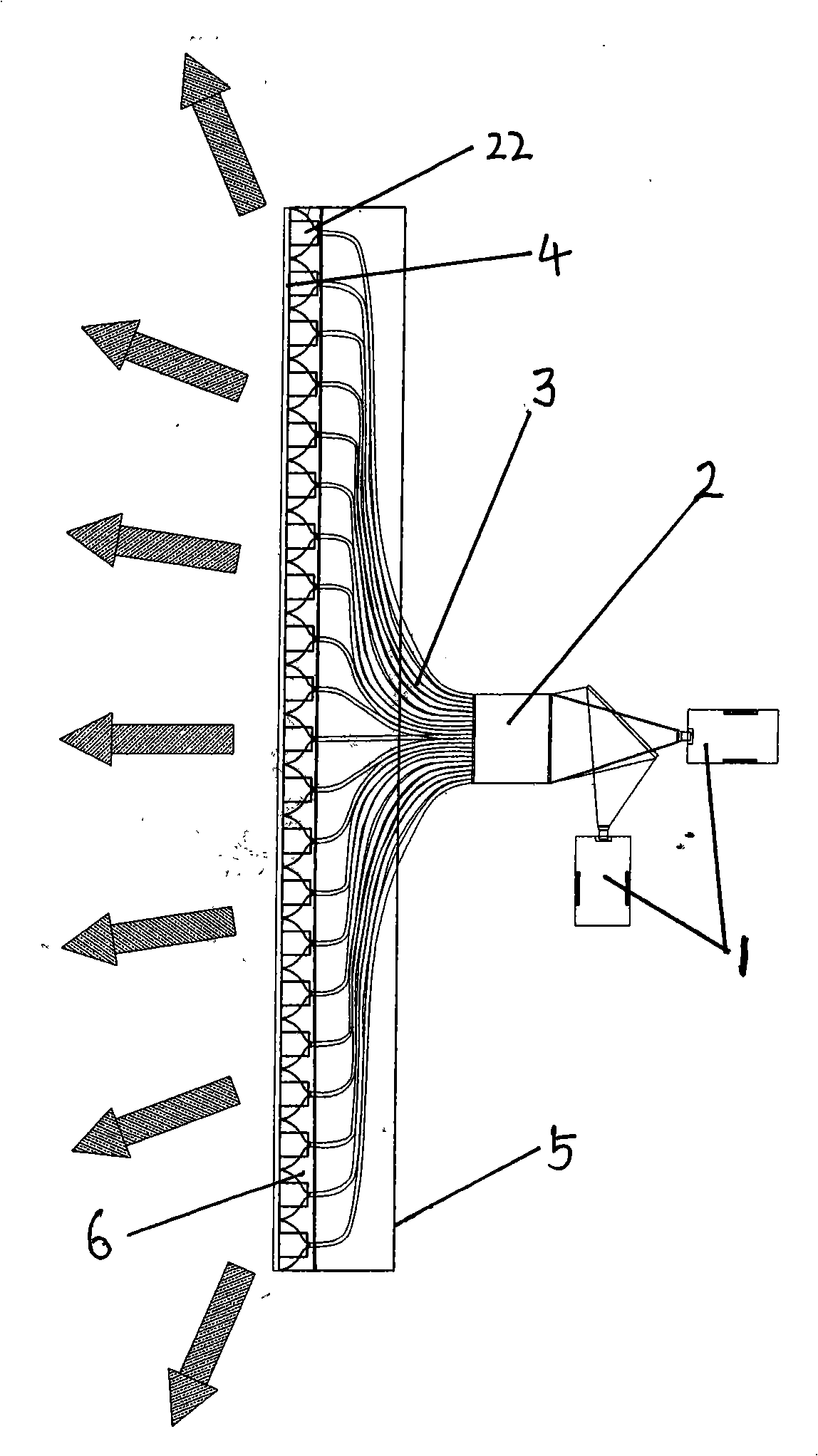

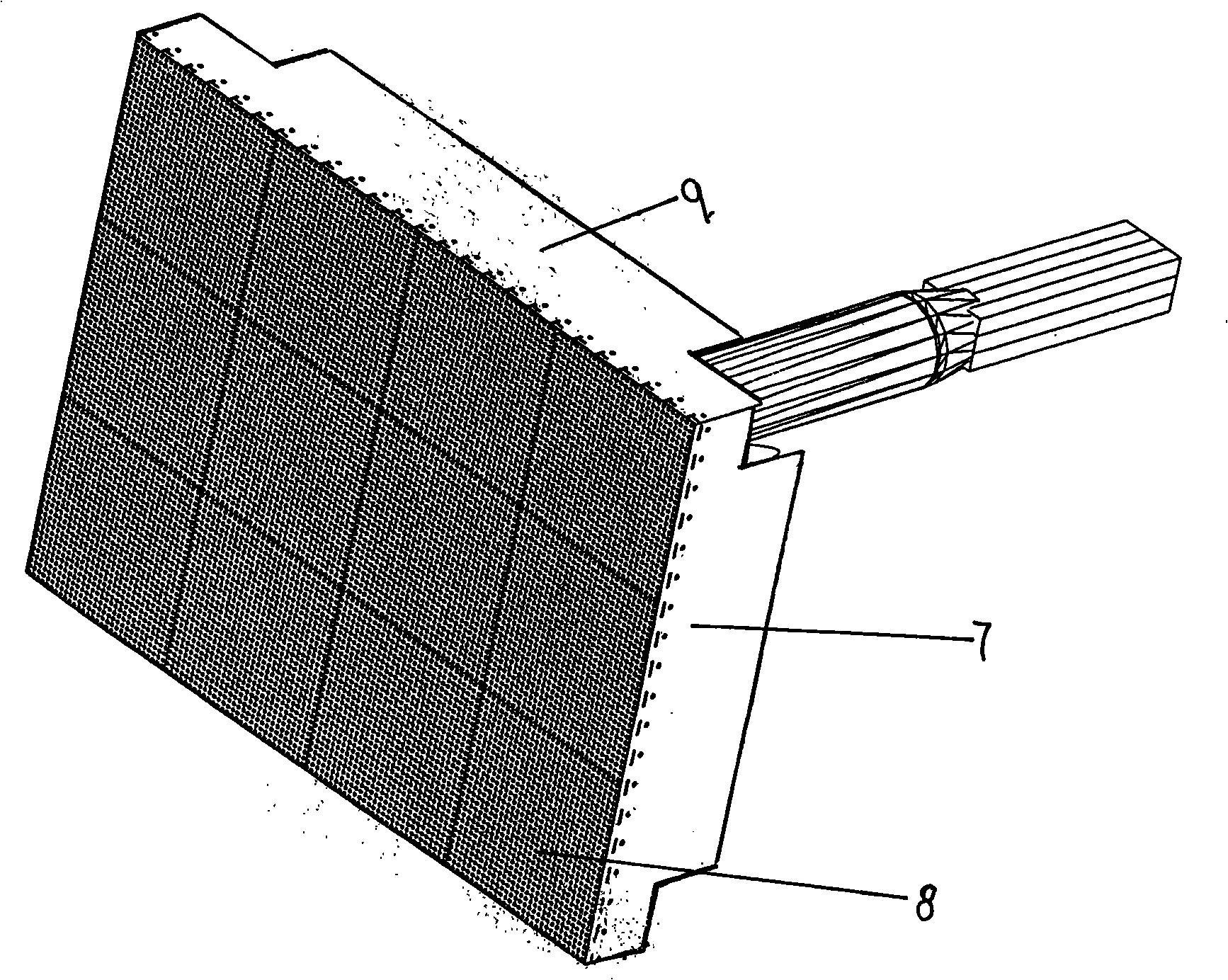

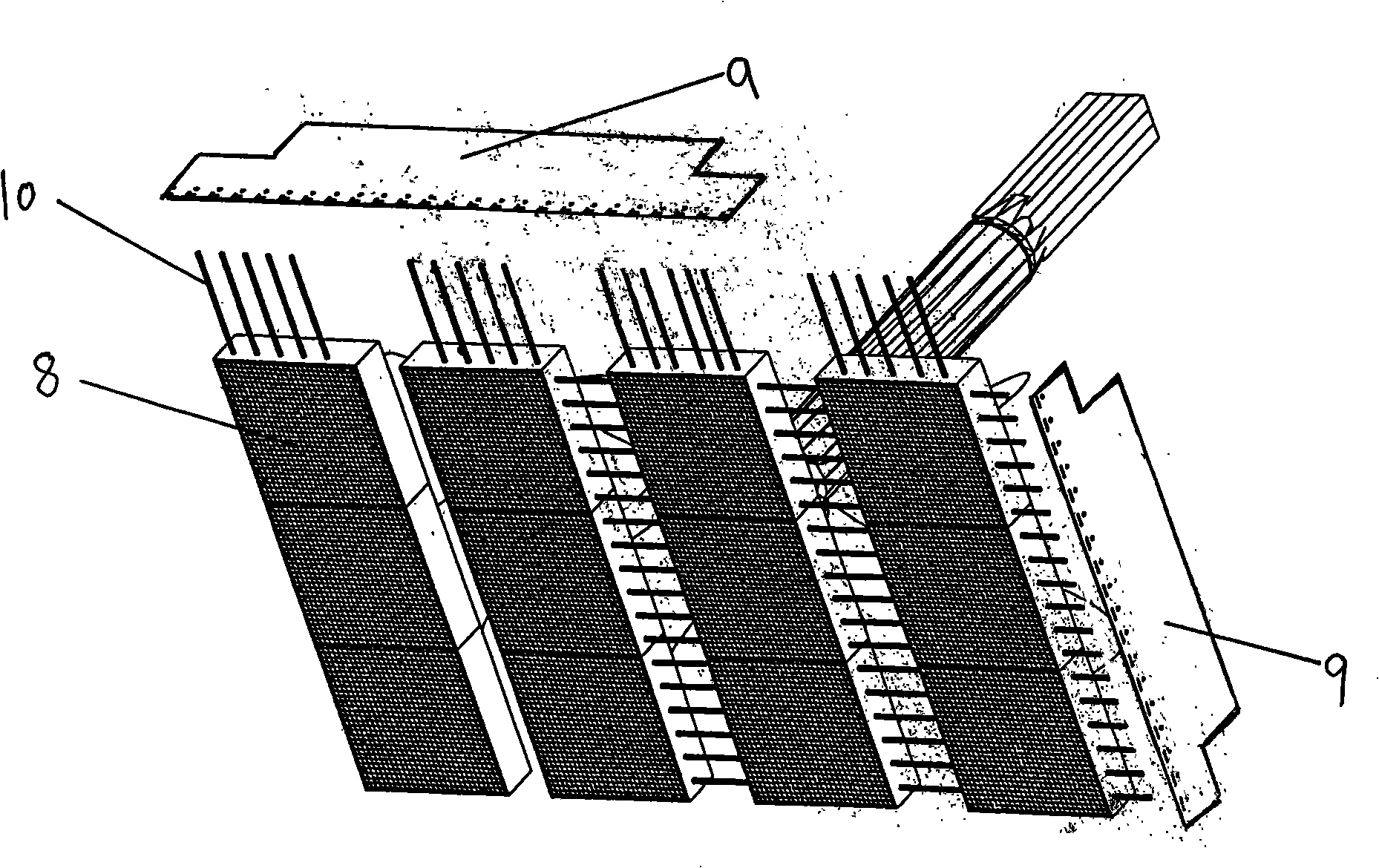

[0030] As shown in the accompanying drawings, an optical fiber display screen is composed of a projector 1, an optical fiber bundle 2, an optical fiber 3, and a screen body 4. The structures and connections of the projector 1, optical fiber bundle 2, and optical fiber 3 are the same as those of the prior art. Not to repeat, the feature of the present invention is that screen body 4 is made up of display screen outer frame 5 and box body 6, and box body 6 is made up of several box body units 7, and box body unit 7 is made up of several module units 8, box body Side plate 9, fastening link 10 and connector are made up, module unit 8 is made up of several clips 11, lens 12, pinch plate 13, fastening link 14 and connector, clip 11 among the present invention is lath shape, the clip 11 is provided with several optical fiber holes, the upper end surface of the clip is evenly prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com