Spray coating device

A technology of spraying equipment and spraying device, which is applied in the field of spraying equipment, can solve the problems of being close to the object or moving into the object, the cost of replacing equipment is high, and it takes a long time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

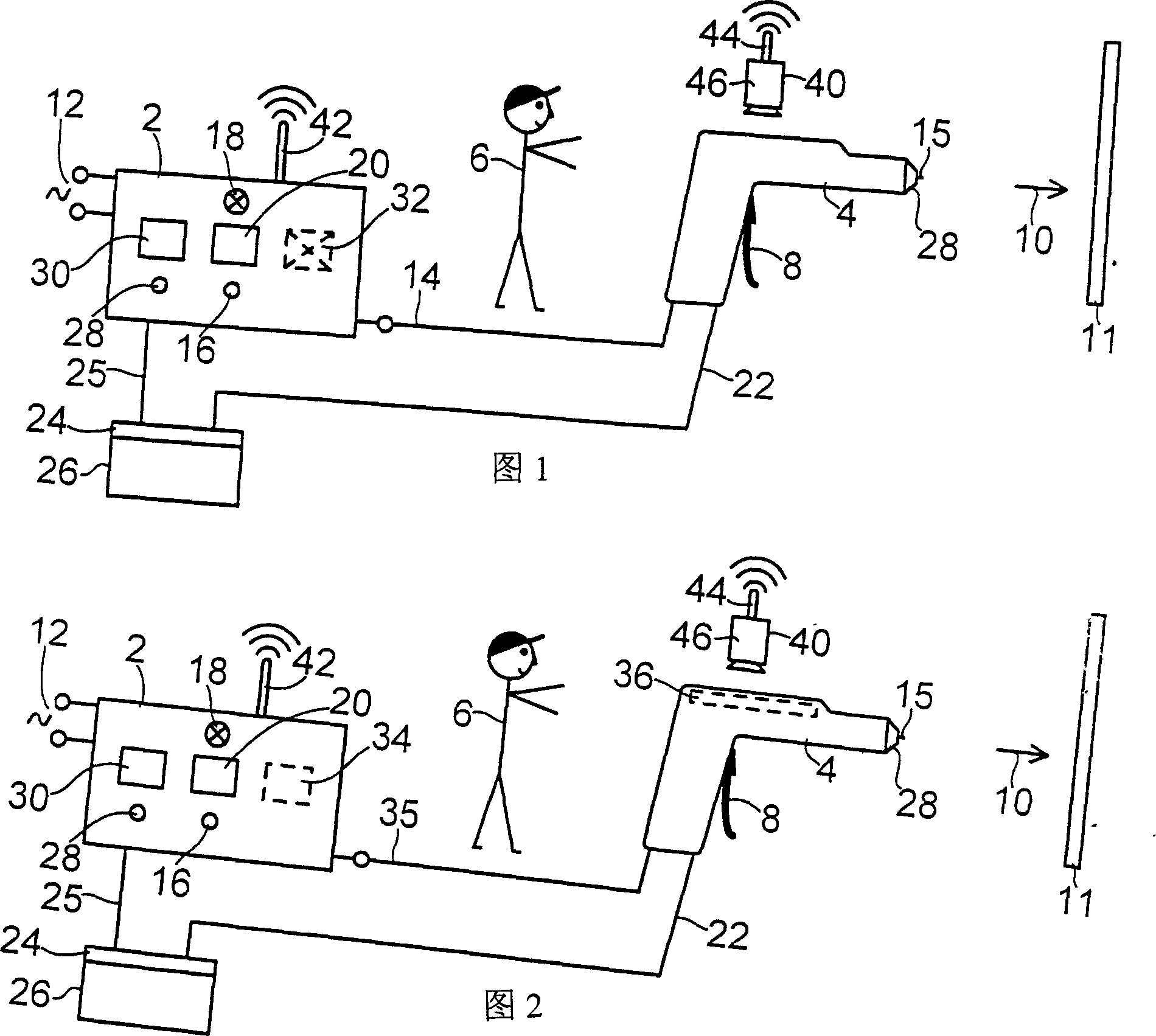

[0016] Fig. 1 shows an electric control device 2 and an electric spray gun 4, and this electric spray gun 4 is manually operated by the operator 6 and is switched on and off by driving the starter 8, thereby spraying the spraying material in the form of spray beam 10 to the desired location. Spray on the object 11.

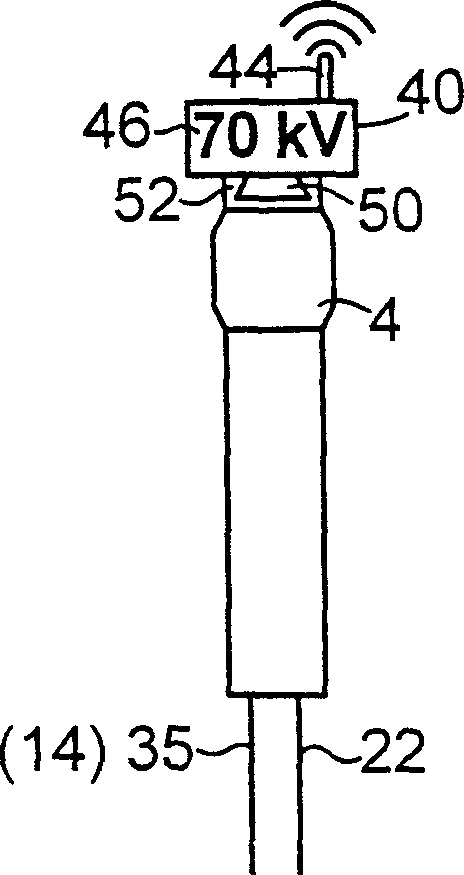

[0017] The control device 2 has a power grid connection line 12 on the one hand, and is connected to the electric spray gun 4 through a cable 14 on the other hand, and is used to at least provide electric energy to the high voltage electrode 15, thereby generating a high voltage potential of 1000- 16000V (volts), charges the spray material and generates an electromagnetic field between at least one high voltage electrode 15 and the object 11 to be sprayed. Preferably, the control device 2 is designed in such a way that not only a single high voltage value but also different high voltage values can be selectively adjusted for the high voltage electrode 15 via the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com