T-shaped integral-rotation adjustable cantilever base

A wrist-arm and integral technology, applied in the field of T-shaped integral rotating adjustable wrist-arm base, can solve the problems of low working efficiency of flexible mobile catenary, affecting the efficiency of cargo loading and unloading operations, and heavy maintenance workload.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in detail below in combination with specific embodiments.

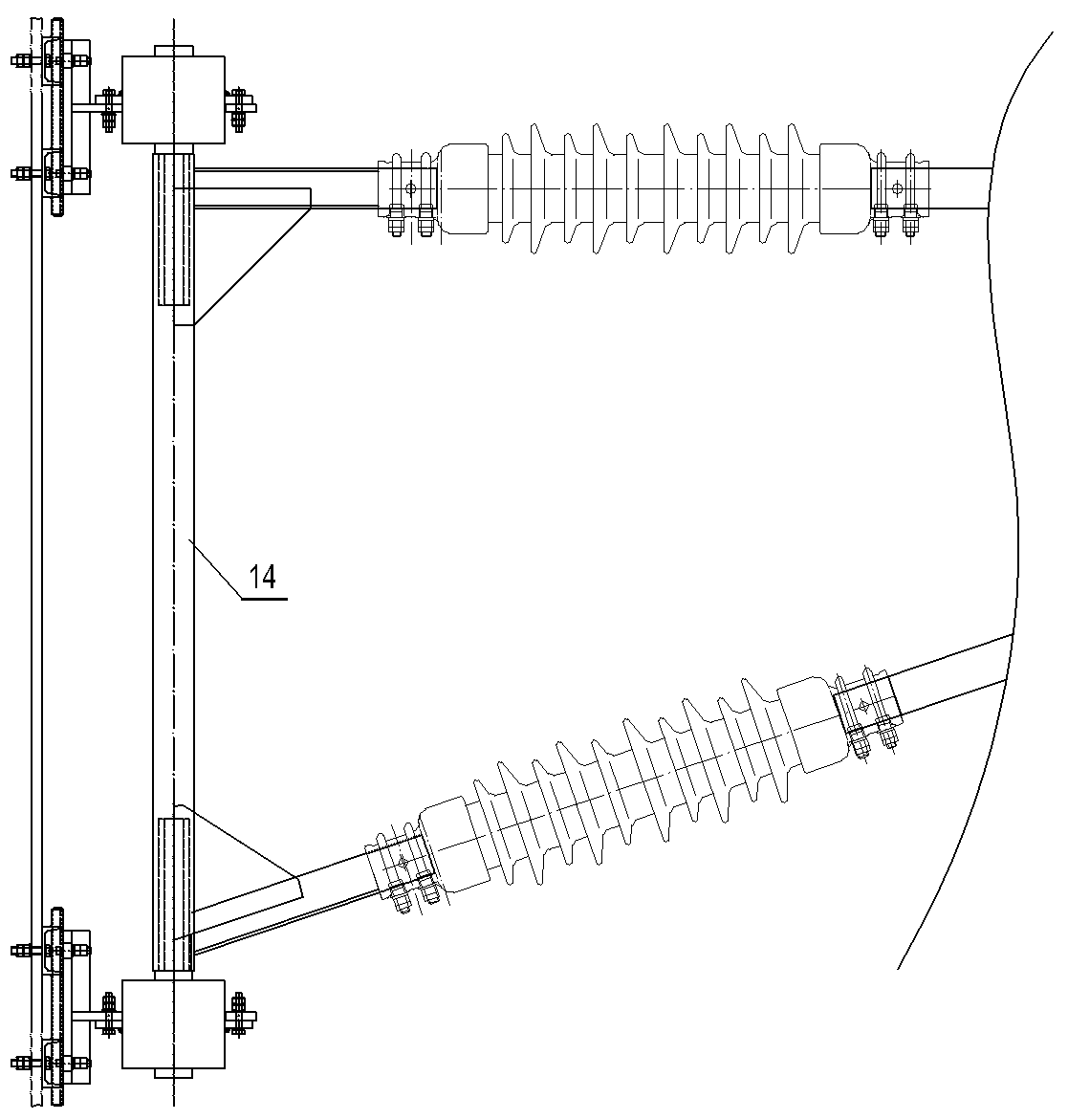

[0039] The invention relates to a T-shaped integrally rotatable adjustable wrist arm base, which mainly satisfies the functions of adjustment, fixation and free rotation of the horizontal lateral movement arm structure in a flexible mobile catenary.

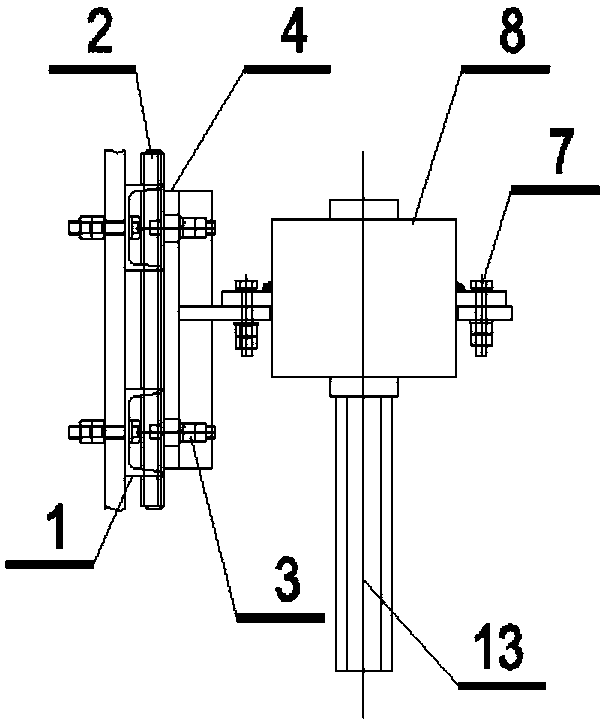

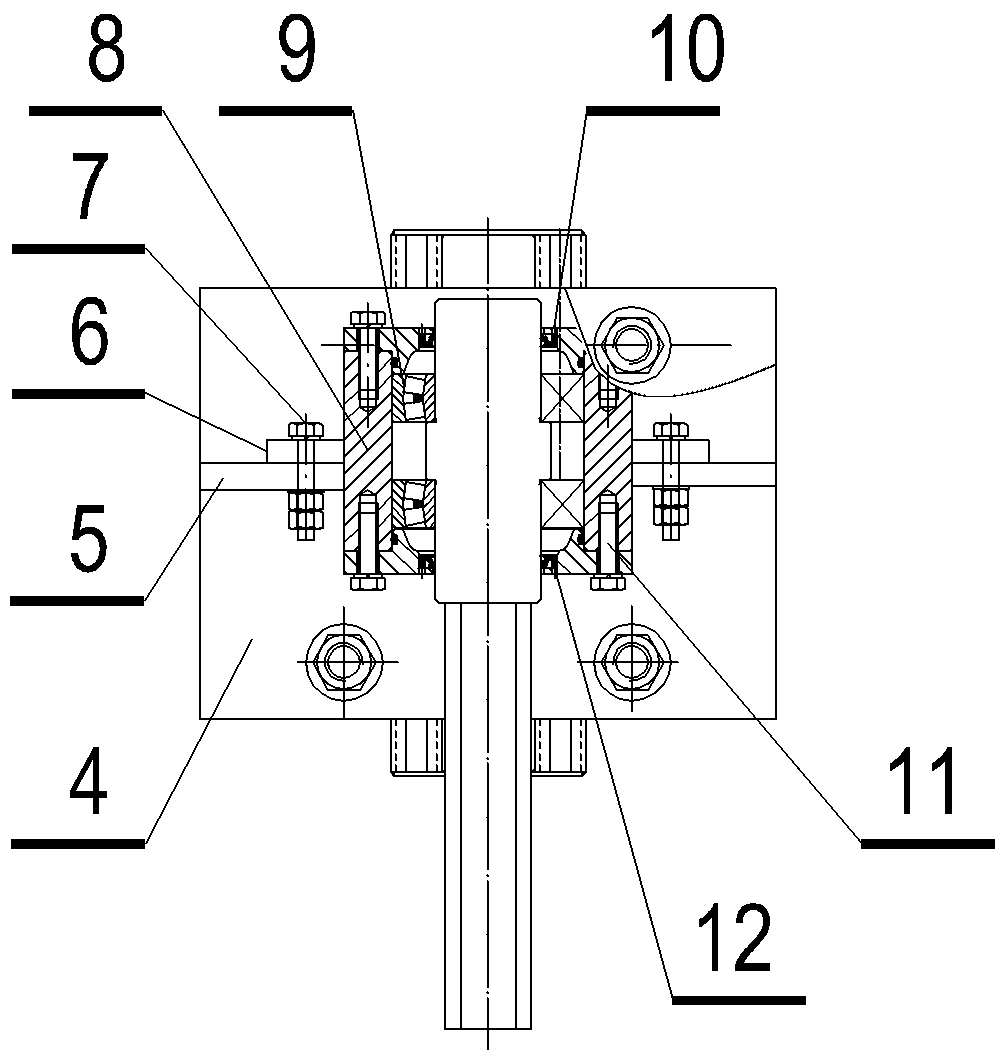

[0040] The specific structure includes a base body 4 fixed on the pillar and installed vertically. The base body 4 is fixed to the channel 2 through the connecting bolt 3 and fixed by welding. The channel 2 is fixed to the pillar through the channel steel 1. The hug method is fixed. The base body 4 is fixed on the vertical channel 2 by bolts, and the position adjustment of the T-shaped overall rotation adjustable wrist arm base can be realized by adjusting the fastening position of the bolts up and down in the channel.

[0041] A horizontal connecting ear 5 is provided on the side of the base body 4 , and stiffeners are wel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com