Elevator single brake set redundancy hydraulic control loop

A technology of control loop and brake, applied in the direction of hoisting device, etc., can solve the problems of low braking pressure control accuracy, poor safety redundancy of hydraulic circuit, slow response, etc., so as to improve the safety redundancy and response of the system. Good characteristics and system stability, high pressure control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

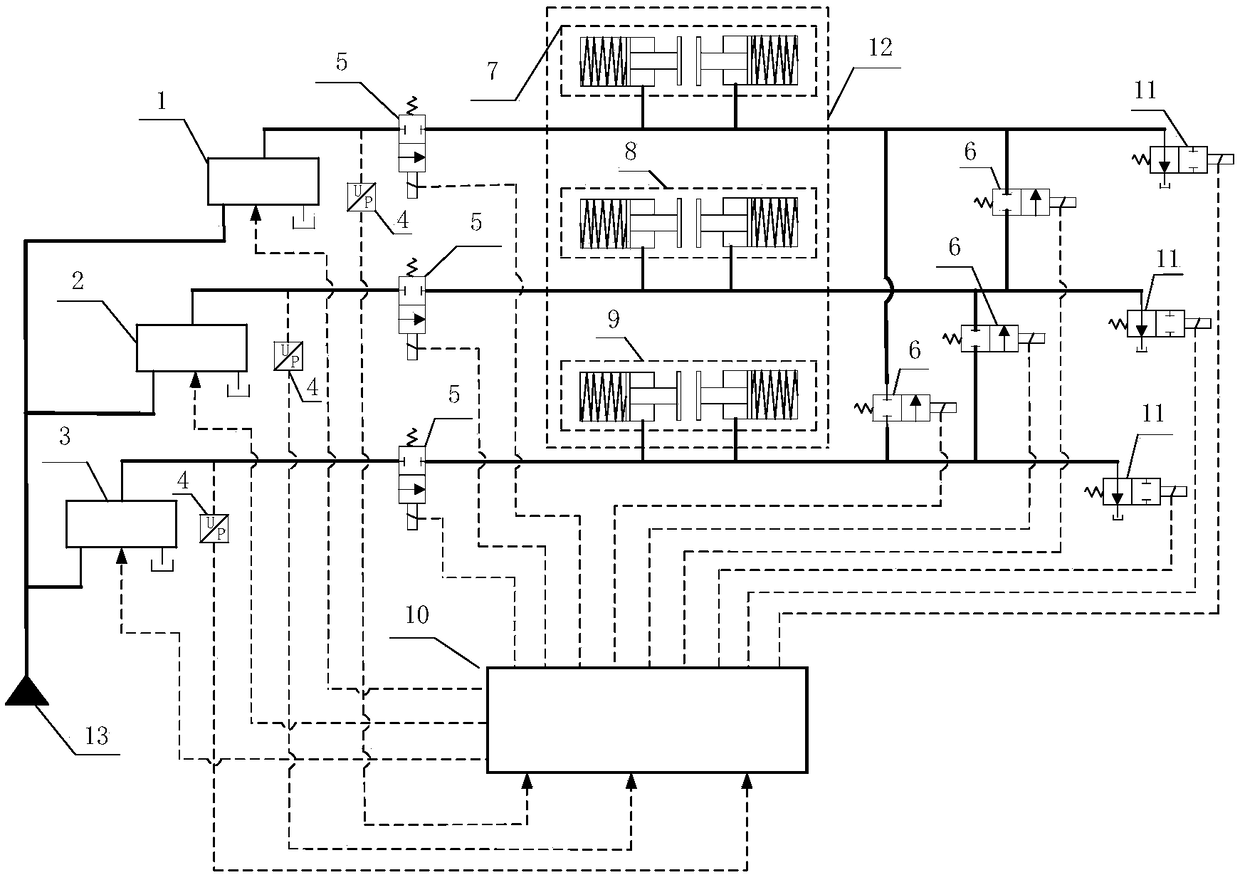

[0011] Introduce detailed technical scheme of the present invention below in conjunction with accompanying drawing:

[0012] Redundant hydraulic control circuit for hoist single brake group, including: E1 brake pressure regulating valve 1, E2 brake pressure regulating valve 2, E3 brake pressure regulating valve 3, 3 pressure sensors 4, 3 A1 electromagnetic reversing valve 5, three A3 electromagnetic reversing valves 6, controller 10, three C1 electromagnetic reversing valves 11, D single brake group 12 and oil source 13; among them, D single brake group and Including: D1 brake 7, D2 brake 8 and D3 brake 9.

[0013] The oil source is respectively connected to the oil inlet ports of E1 brake pressure regulating valve, E2 brake pressure regulating valve and E3 brake pressure regulating valve through pipelines; E1 brake pressure regulating valve, E2 brake pressure regulating valve Pressure sensors are respectively installed at the oil outlets of valve and E3 brake pressure regula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com