Method for continuously recycling PGMEA from PGMEA/water solution through extractive rectification

A technology of extractive distillation and extractive distillation column is applied in the field of continuous dehydration of PGMEA/aqueous solution to achieve good social and economic benefits and simple process flow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

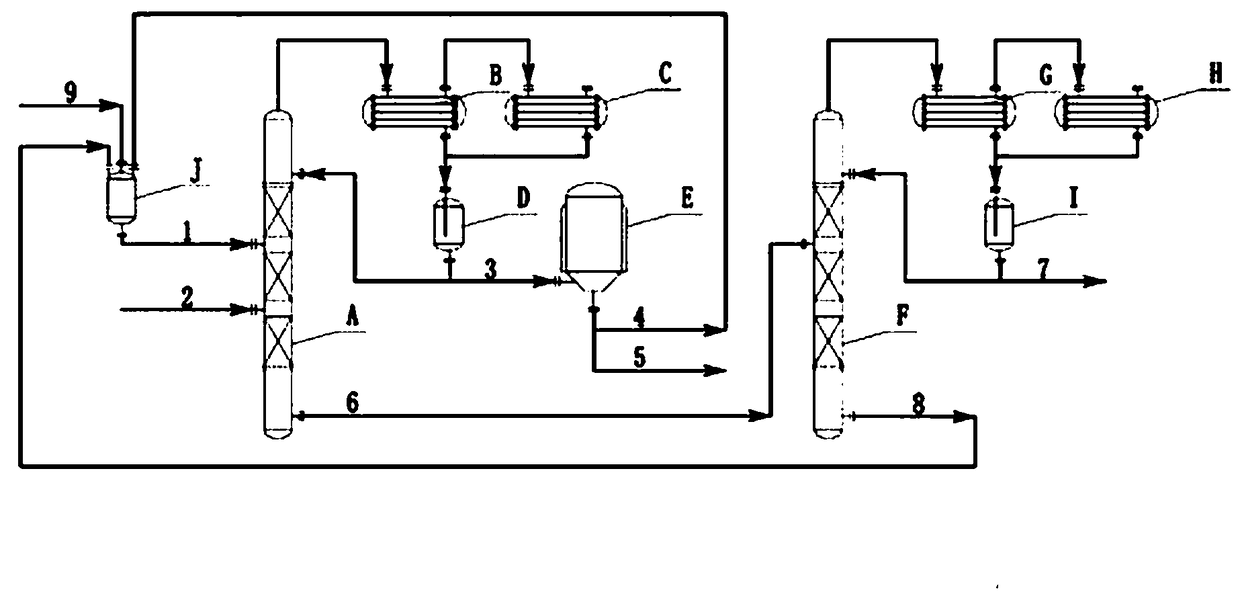

[0022] Such as figure 1 As shown, the PGMEA / water solution 2 to be treated and the extractant 1 are continuously fed to the extractive distillation column A respectively. Extractant adopts ethyl benzyl ether, and the massfraction of PGMEA in PGMEA / water solution is 10%, and feed flow rate is 200kg / h, and the circulating flow rate of extractant ethyl benzyl ether is 200kg / h, and now ethyl Benzyl ether is 10 times the mass of PGMEA. The extractive distillation column A contains 31 theoretical plates, the PGMEA / water solution to be treated is continuously fed from the 14th theoretical plate of the extractive distillation column A, and the extractant ethyl benzyl ether is continuously fed from the second theoretical plate of the extractive distillation column A Feed, the material is heated into steam in the tower kettle, and enters the extractive distillation tower condenser B and the extractive distillation tower catcher C to condense, and the condensate enters the extractive di...

Embodiment 2

[0026] The difference between this embodiment and embodiment one is: the massfraction of PGMEA in PGMEA / water solution 2 is 50%, the feed flow rate is 50kg / h, and the extraction agent adopts ethyl benzyl ether, the content of ethyl benzyl ether The circulating flow rate is 100kg / h, and at this time, the ethyl benzyl ether is 4 times the mass of PGMEA. The extractive distillation column A contains 40 theoretical plates, the PGMEA / water solution to be treated is continuously fed from the 21st theoretical plate of the extractive distillation column A, and the extraction agent ethyl benzyl ether is continuously fed from the second theoretical plate of the extractive distillation column A Feed, the material is heated into steam in the tower kettle, and enters the extractive distillation tower condenser B and the extractive distillation tower catcher C to condense, and the condensate enters the extractive distillation tower reflux tank D, and the extractive distillation tower reflux ...

Embodiment 3

[0030]The difference between the present embodiment and embodiment two is: the massfraction of PGMEA in the PGMEA / water solution is 95%, the feed flow rate is 100kg / h, and the circulation flow rate of the extractant ethyl benzyl ether is 190kg / h, At this time, the ethyl benzyl ether is twice the mass of PGMEA. The extractive distillation column A contains 20 theoretical plates, the PGMEA / water solution to be treated is continuously fed from the 12th theoretical plate of the extractive distillation column A, and the extraction agent ethyl benzyl ether is continuously fed from the second theoretical plate of the extractive distillation column A Feed, the material is heated into steam in the tower kettle, and enters the extractive distillation tower condenser B and the extractive distillation tower catcher C to condense, and the condensate enters the extractive distillation tower reflux tank D, and the extractive distillation tower reflux ratio is 1, the flow rate of the overhead...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com