Car starting motor and one-way clutch structure thereof

A technology of one-way clutches and fixed sleeves, which is applied in the direction of one-way clutches, clutches, mechanical equipment, etc., can solve the problems of the overall axial length of the one-way clutch deceleration assembly and occupy the space of the starter motor, etc., to shorten the axial distance , optimize the installation structure, and reduce the overall volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

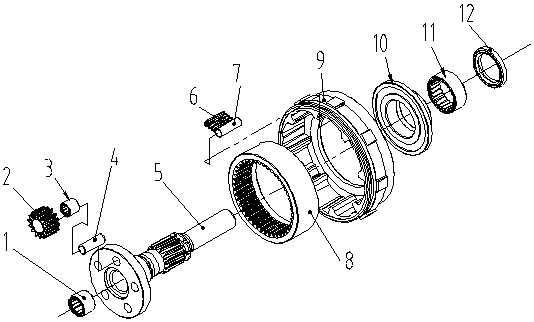

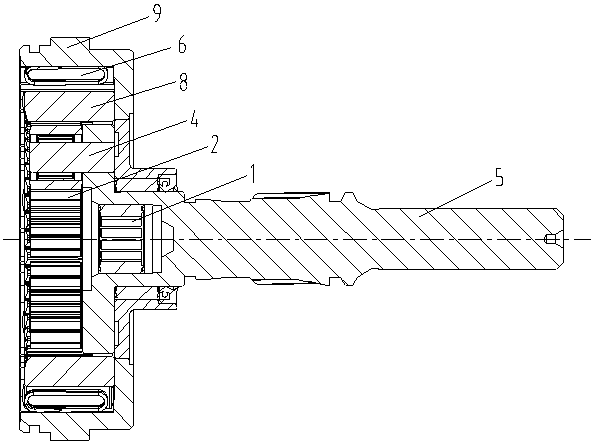

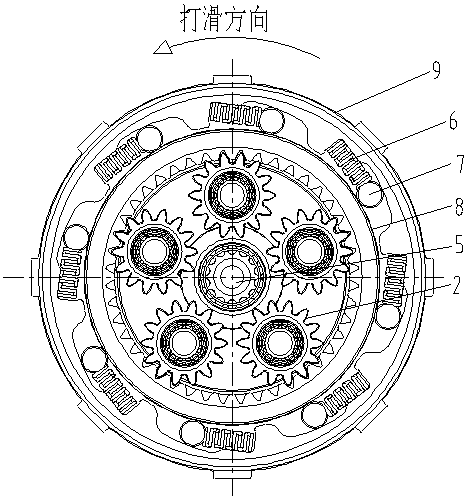

[0029] A one-way clutch structure, including: a fixed ring 9, an inner ring gear 8 and a planetary shaft 5, the inner ring gear 8 is assembled on the inner wall of the fixed ring 9, and one side of the planetary shaft 5 has an end face flange 501.

[0030] The end flange 501 is equipped with a plurality of evenly distributed planetary gears 2 in the circumferential direction, and the planetary shaft 5 equipped with the planetary gears 2 is socketed inside the inner ring gear 8 by means of the end flange 501 and then assembled in the fixed ring 9 .

[0031] The inner ring gear 8 is arranged concentrically with the fixed ring 9 , and the inner ring gear 8 has an outer peripheral surface capable of cooperating with the fixed ring 9 and an inner tooth surface capable of meshing with the planetary gear 2 .

[0032] A plurality of wedge-shaped positioning grooves 901 are evenly distributed on the inner wall of the fixed ring 9, and rollers 7 and flat springs 6 are arranged in the we...

Embodiment 2

[0043] A starter motor for automobiles, including a one-way clutch structure, the one-way clutch structure, including: a fixed ring 9, an inner ring gear 8 and a planetary shaft 5, the inner ring gear 8 is assembled on the inner wall of the fixed ring 9, and the planetary shaft 5 One of the sides has a face flange 501 .

[0044] The end flange 501 is equipped with a plurality of evenly distributed planetary gears 2 in the circumferential direction, and the planetary shaft 5 equipped with the planetary gears 2 is socketed inside the inner ring gear 8 by means of the end flange 501 and then assembled in the fixed ring 9 .

[0045] The inner ring gear 8 is arranged concentrically with the fixed ring 9 , and the inner ring gear 8 has an outer peripheral surface capable of cooperating with the fixed ring 9 and an inner tooth surface capable of meshing with the planetary gear 2 .

[0046] A plurality of wedge-shaped positioning grooves 901 are evenly distributed on the inner wall o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com