Micro-gyroscope sliding mode control method with error limitation

A control method and micro-gyroscope technology, applied in the direction of adaptive control, general control system, control/adjustment system, etc., can solve the problems that the MEMS micro-gyroscope error indicators cannot meet the design requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0074] The technical solutions of the present invention will be further described in detail below in conjunction with specific embodiments.

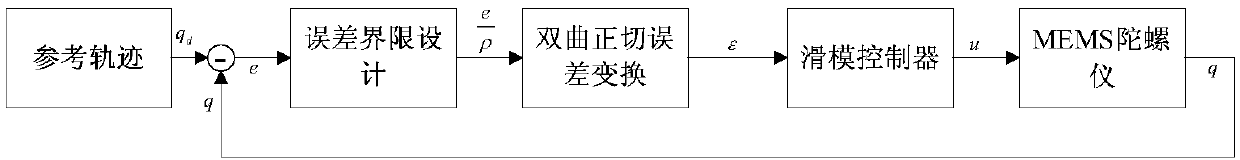

[0075] Such as figure 1 A micro-gyroscope sliding mode control method with error limitation shown includes the following steps:

[0076] 1) Establish a mathematical model of the micro gyroscope;

[0077] 2) The design of the error limit boundary;

[0078] 3) Equivalent error transformation;

[0079] 4) Sliding mode surface design using equivalent error;

[0080] 5) Design of control force;

[0081] 6) Proof of stability.

[0082] The mathematical model of the micro-gyroscope in the aforementioned step 1) is:

[0083]

[0084] in

[0085] Where x, y represent the displacement of the gyroscope in the direction of the XY axis, d xx d yy is the elastic coefficient of the spring in the direction of XY axis, k xx k yy is the damping coefficient in the direction of XY axis, d xy 、k xy is the coupling parameter caused by proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com