Microelectromechnical piezoelectric ultrasonic transducer with special modal shape

A modal shape, voltage and electricity technology, applied in the direction of fluid using vibration, etc., can solve the problems of low space utilization and low sound pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further elaborated and illustrated below in conjunction with the accompanying drawings and specific embodiments. The technical features of each embodiment in the present invention can be combined accordingly under the premise that there is no conflict with each other.

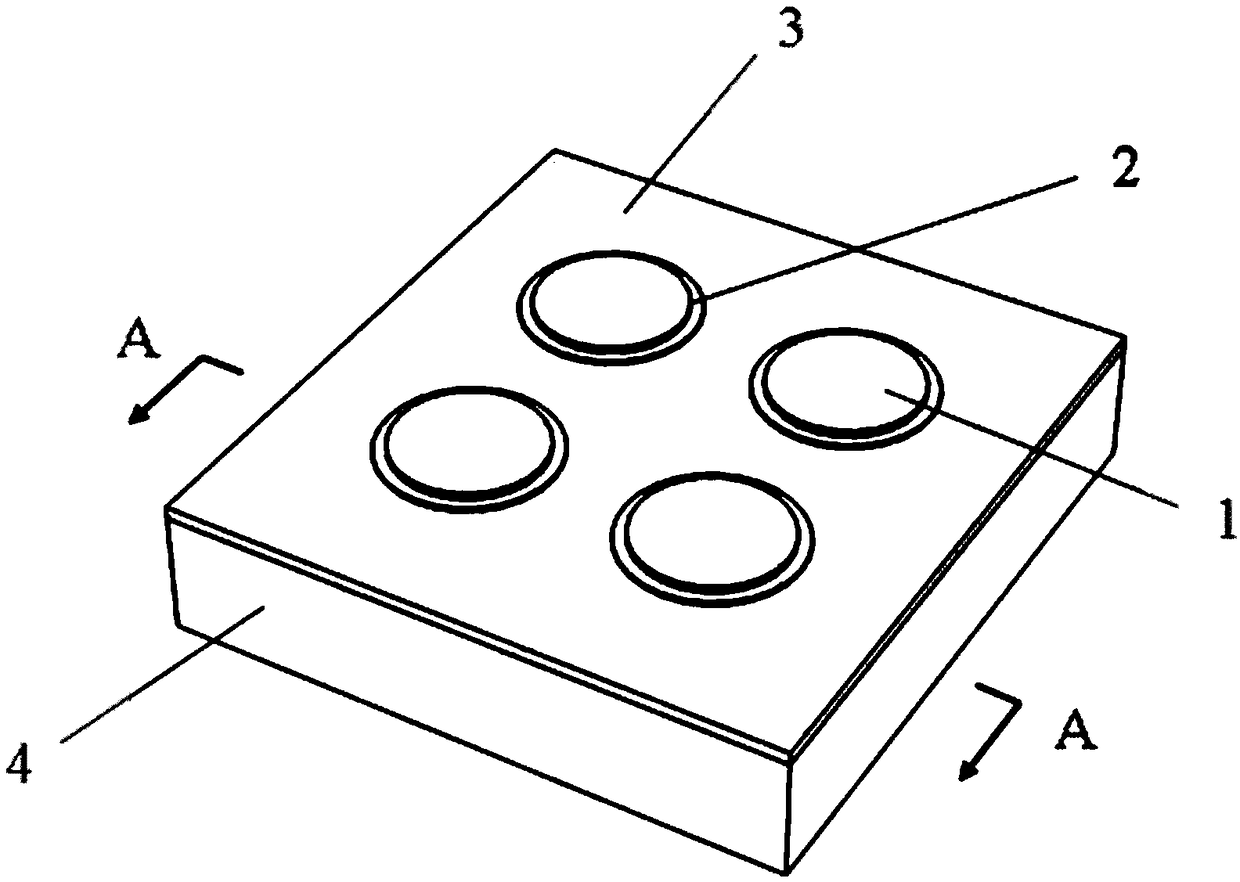

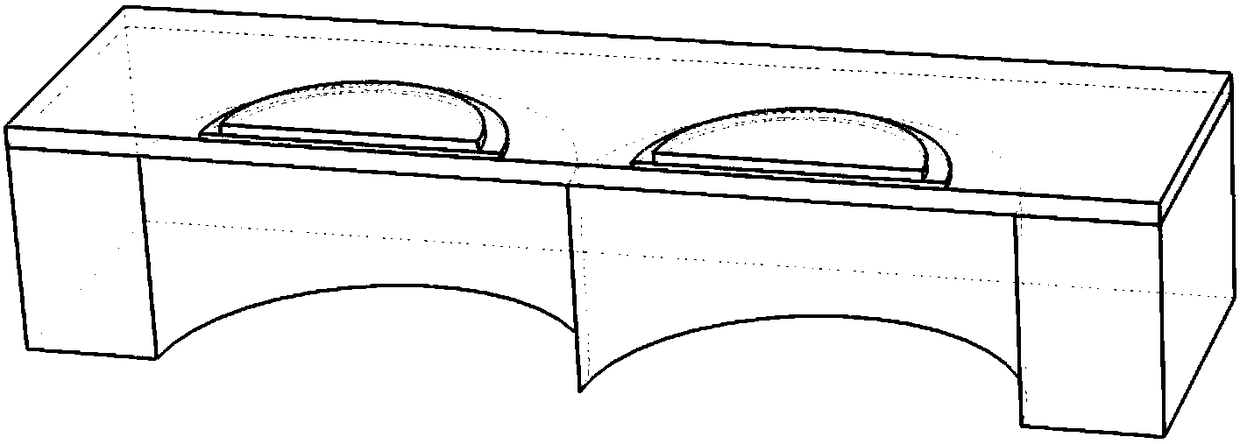

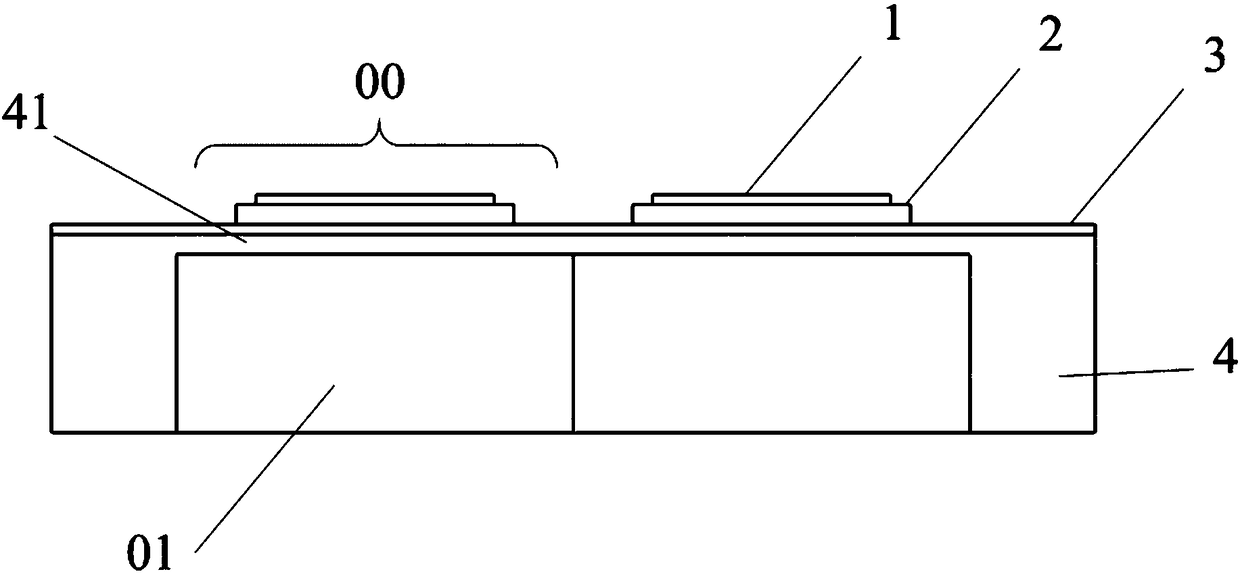

[0029] Such as Figure 1~3 As shown, the microcomputer piezoelectric ultrasonic transducer with a specific mode shape includes a substrate 4, a bottom electrode 3, a piezoelectric layer 2 and an upper electrode 1, and the middle part of the back of the substrate 4 has a groove-shaped cavity, so that the front of the substrate 4 The elastic structural layer 41 is formed. The trough-shaped cavity is formed by four cylindrical cavity units 01 of the same size and height. Clamping between them forms a cylindrical base 4 with a rhombus-shaped cross section, and the cylinder also needs to be hollowed out at the same time, so the elastic structural layer 41 is actually in the sha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com