Maintenance spraying trolley for reinforced concrete drainage pipe

A reinforced concrete and drainage pipe technology, applied in the field of spray trucks, can solve the problems of incomplete spraying area, affecting the use effect of reinforced concrete, water pipes unable to spray drainage pipes, etc., to achieve the effect of convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

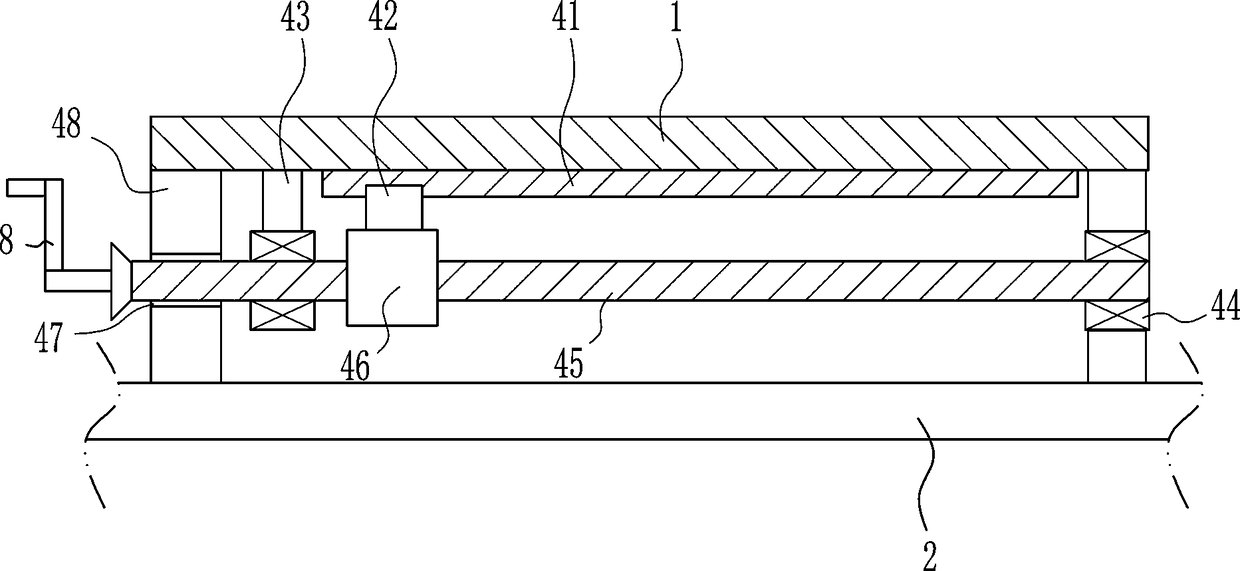

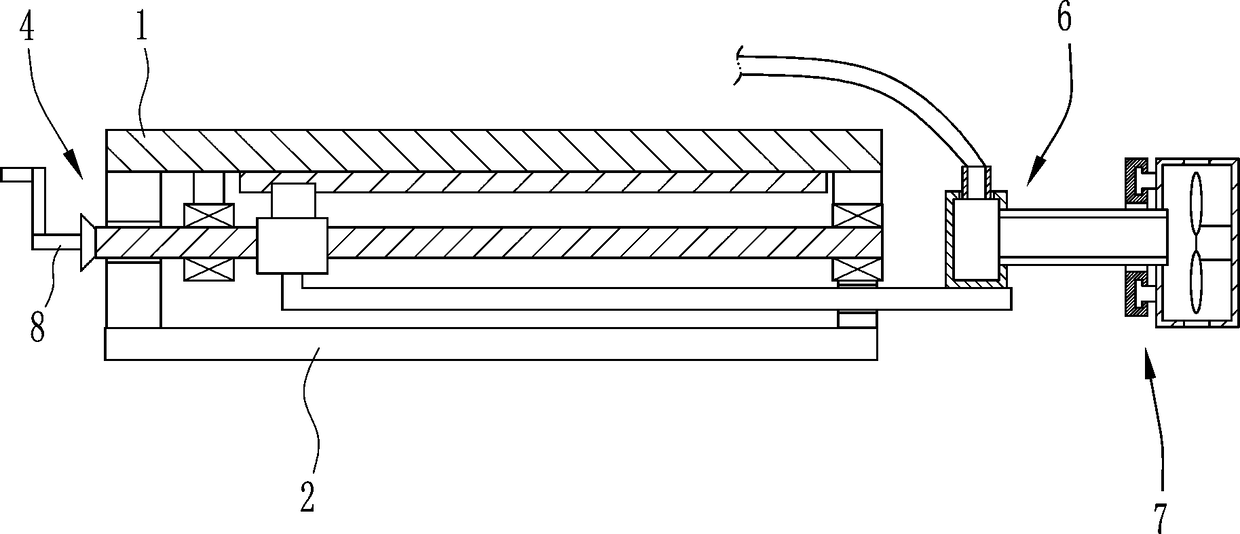

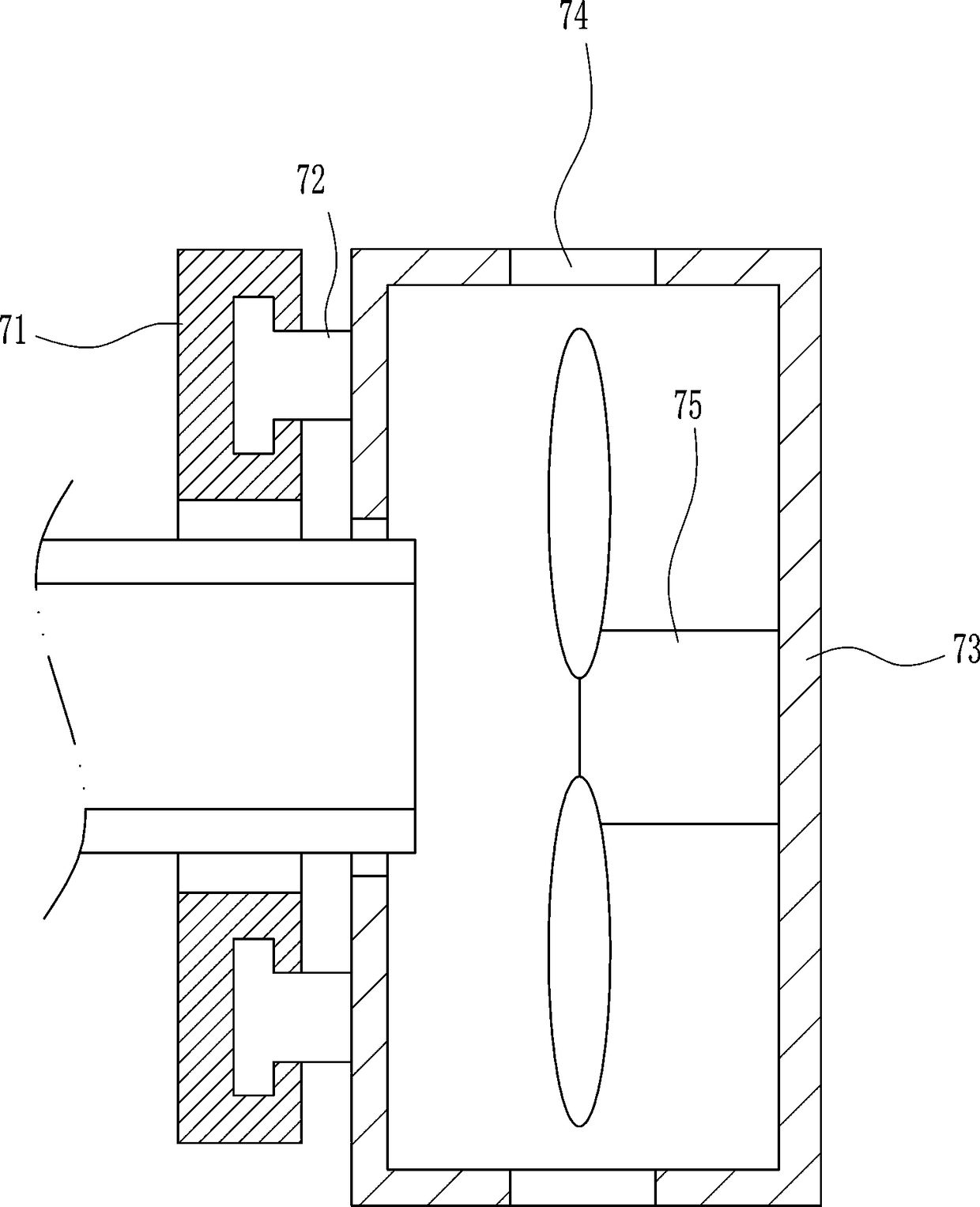

[0037] A maintenance spray vehicle for reinforced concrete drainage pipes, such as Figure 1-9 As shown, it includes a first slide rail 1, a sliding plate 2, a transportation part 3, a horizontal moving part 4, a water storage part 5, a water distribution pipe fitting 6, a spraying part 7, a rotating rod 8 and a telescopic plate 9; the sliding plate 2 and the horizontal The moving part 4 is slidingly connected, and the horizontal moving part 4 is fixedly connected to the top surface of the sliding plate 2; the rotating rod 8 is connected to the horizontal moving part 4 in transmission, and the telescopic plate 9 is connected to the output end of the horizontal moving part 4; the first slide rail 1 is fixed to the On the top surface of the horizontal moving part 4; the water storage part 5 is slidably connected to the first slide rail 1; pipe fitting 6;

[0038] The transportation part 3 includes a second slide rail 31, a moving wheel 32, a first butterfly bolt 34 and a second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com