Automatic stamping machine

An automatic stamping machine and movement technology, applied in the field of stamping machines, can solve the problems of not necessarily accurate stamping position, cumbersome operation process, inconvenient light desktop office, etc., to achieve convenient photo identification and ensure personal safety , Office convenient and labor-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

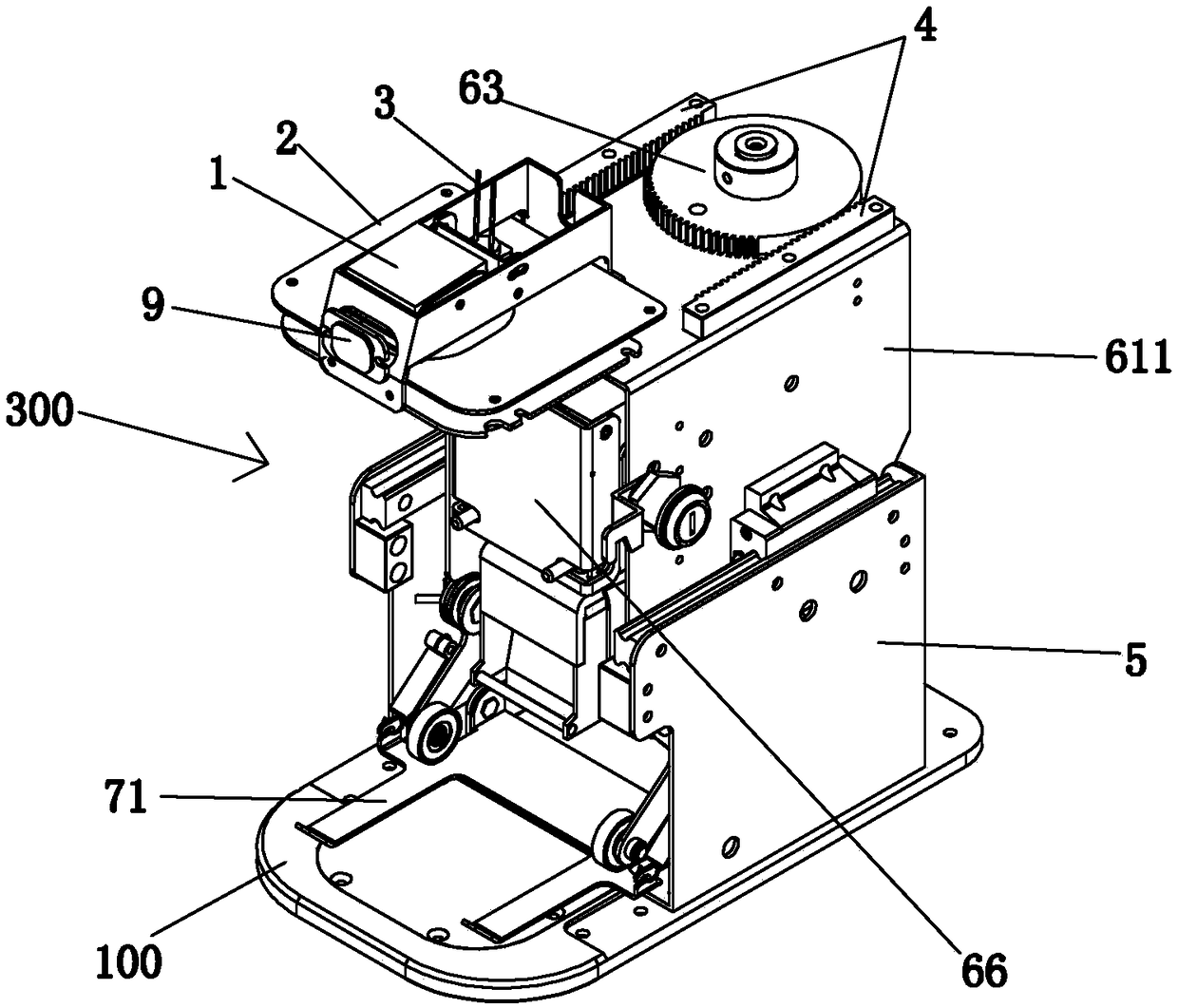

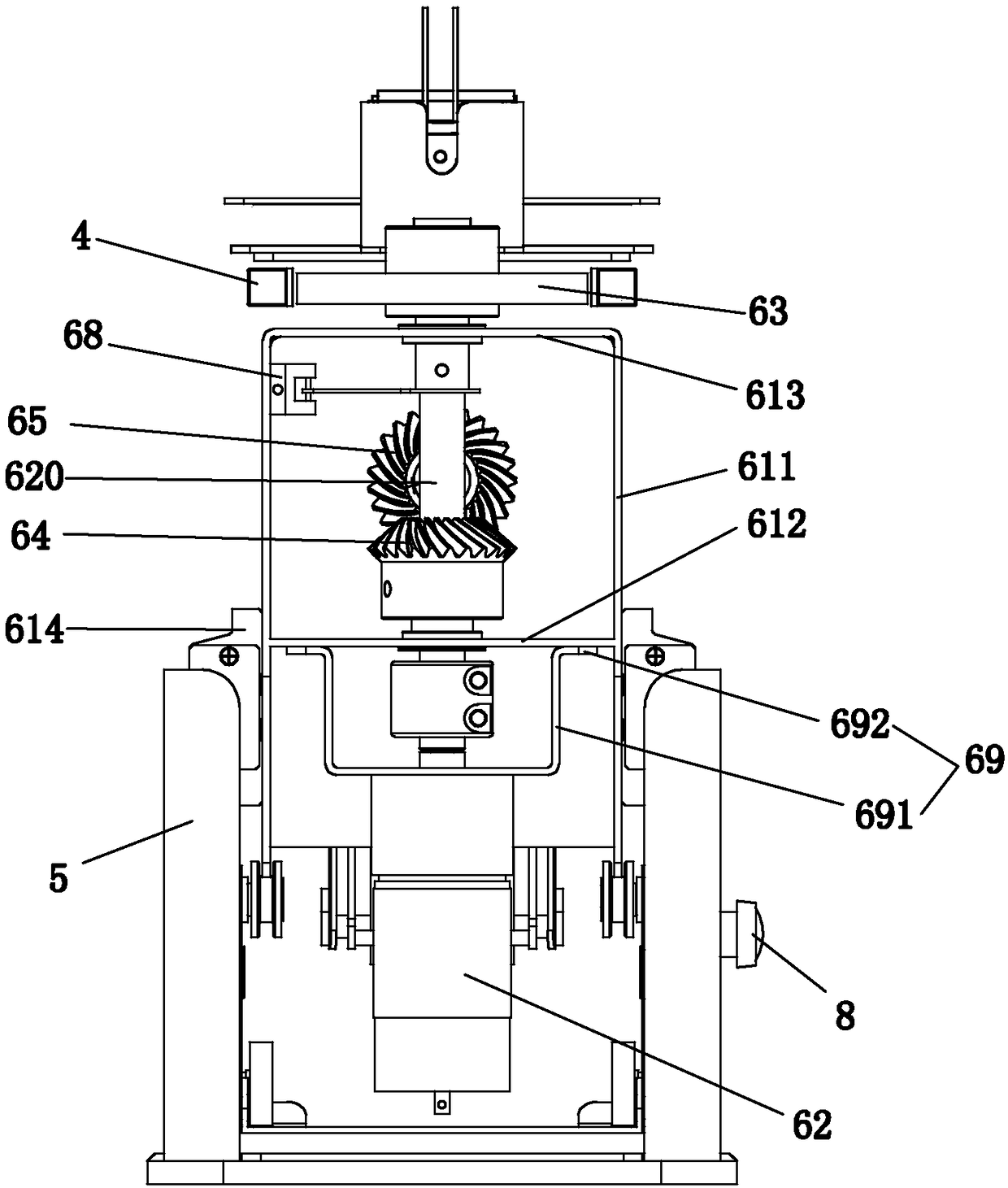

[0024] Such as figure 1 , 2 , 3, 4, 5, 6, and 7, the automatic stamping machine of the present invention is used for stamping documents, and the automatic stamping machine includes a base plate 100, a housing 200 fixedly connected to the base plate 100, a set The functional part 300 in the space enclosed by the base plate 100 and the housing 200 has a gap between the lower end of the front side of the housing 200 and the base plate 100 , and the functional part 300 includes a A camera 1 on the side, a main control board 2 for control, analysis and identification, a positioning cursor 3 arranged on the main control board 2, two left and right racks 4 fixedly connected to the upper rear side of the housing 200, Two fixed plates 5 respectively connected to the left and right sides of the bottom plate 100, the movement 6 connected to the left and right fixed plates 5 movable back and forth, can be pressed down with the movement of the movement 6 forward and backward. The left an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com