Automatic discharging stock bin

A technology of automatic discharging and silo, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of affecting parts processing flow, low production process efficiency and high error rate, so as to adapt to the process rhythm, improve production efficiency and action Simple and reliable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

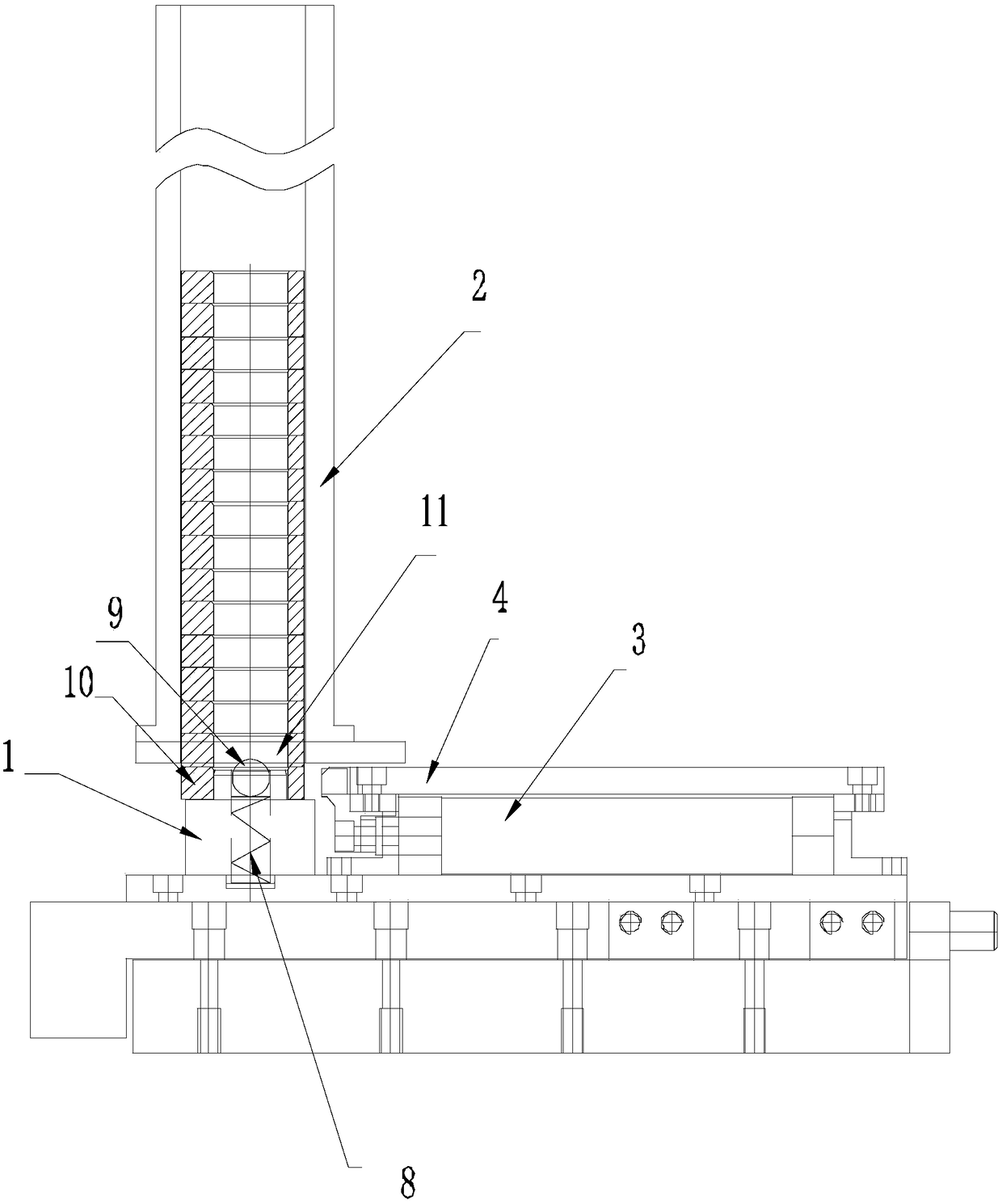

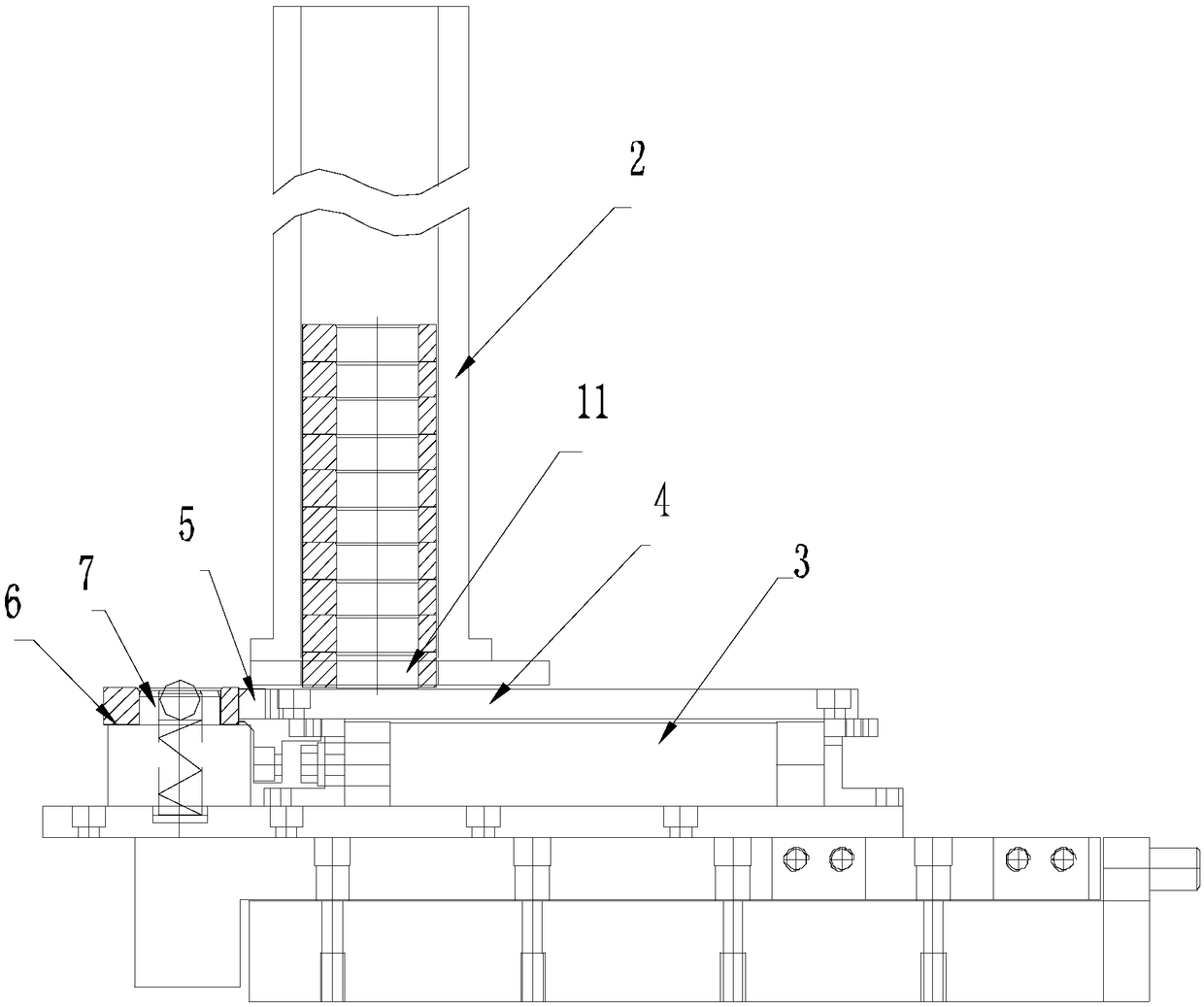

[0015] Such as figure 1 and figure 2 The automatic discharge bin shown includes a parts positioning pile 1, a parts bin 2, a linear motion drive device, and a parts receiving plate 4. The parts bin 2 is a hollow structure with a discharge port at the bottom, and the parts The positioning pile 1 is provided with a positioning platform 6 and a boss 7, the parts positioning pile 1 is located under the parts silo 2, the parts positioning pile 1 is installed at the front end of the linear motion drive device, and the parts receiving plate 4 is located at the bottom of the parts material bin 2. Below the warehouse 2, the part receiving plate 4 is connected with the linear motion driving device. The automatic discharge bin of the present application has two working states of picking up and waiting for a position. When the device is in the picking up working state, the posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com