Foldable cable winding wheel

A winding wheel and folding type technology, which is applied in the field of winding devices of cable cutting machines, can solve the problems of damaged parts, loss, and low cable unloading efficiency, so as to avoid scratches, have a practical and reasonable structure, and solve the inconvenience of unloading cables Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

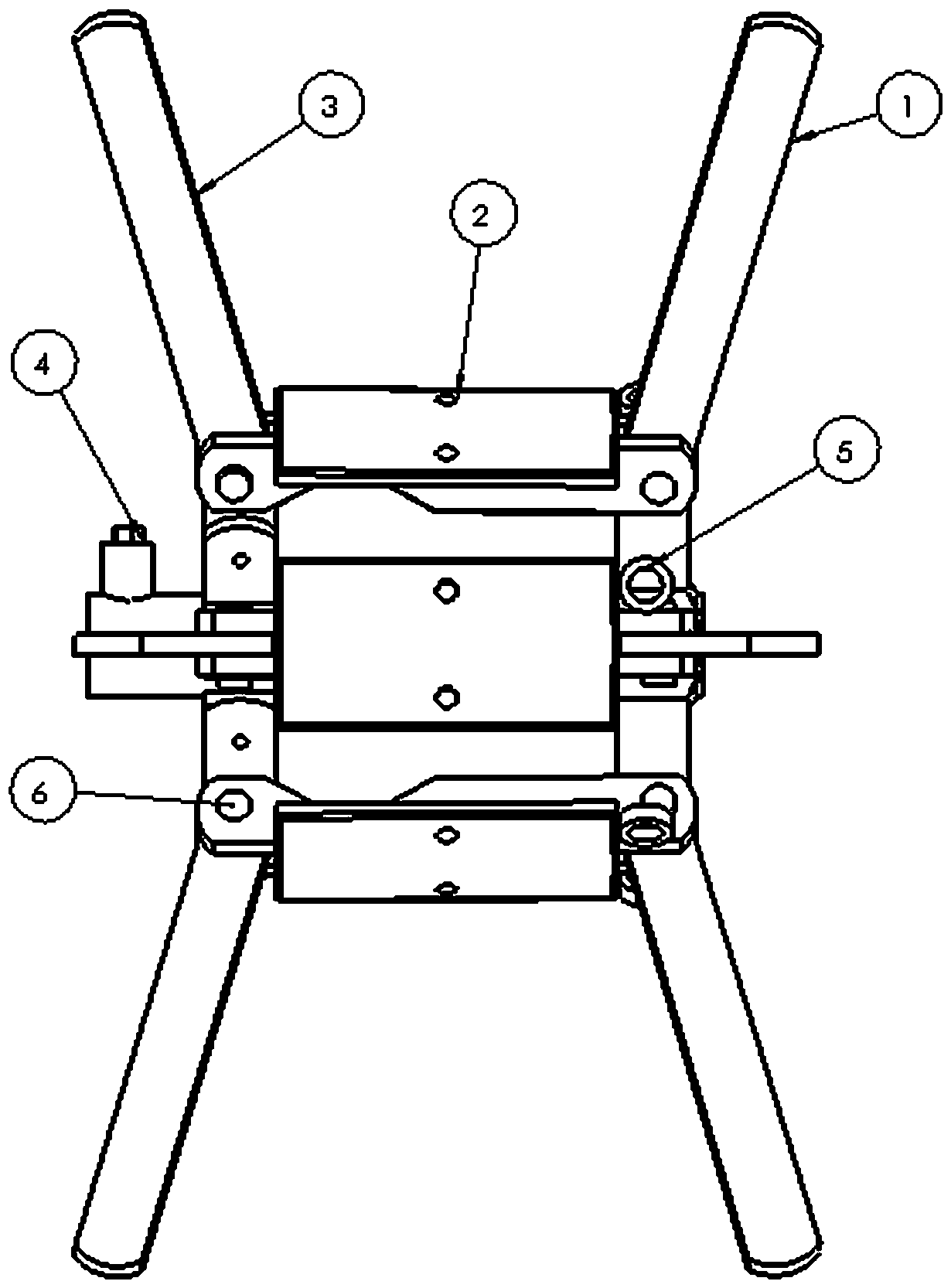

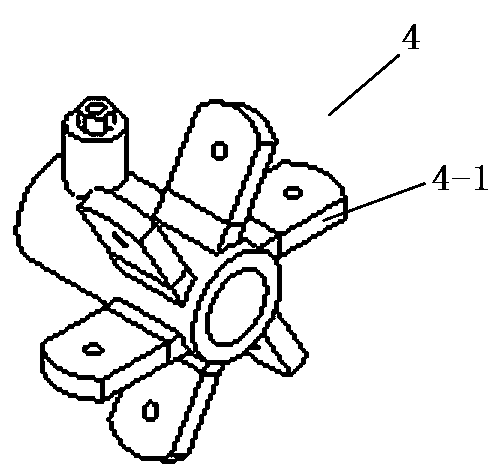

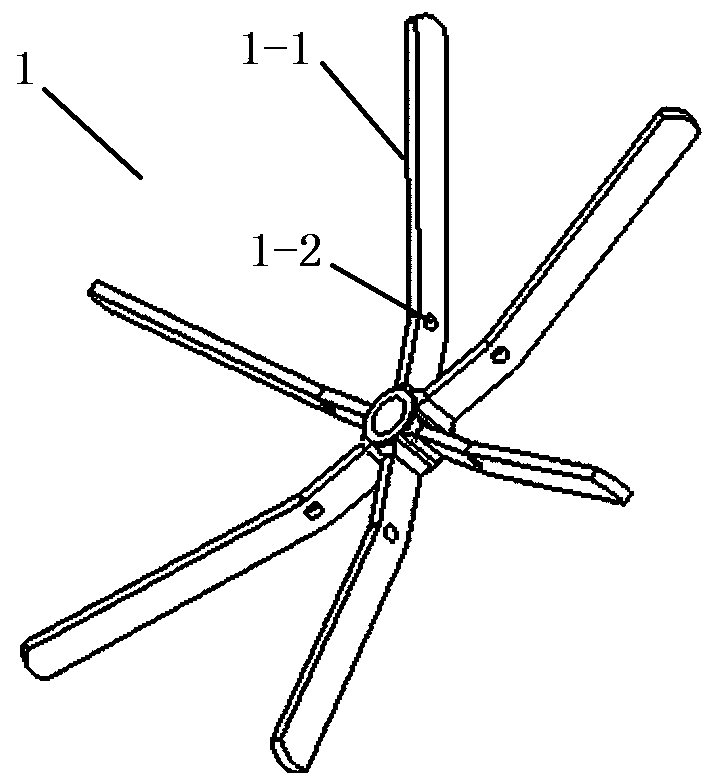

[0023] Refer to attached Figure 1-7 The foldable reel of the present invention includes a base 1, a central shaft 4, a connecting block 2, wings 3 and buckles 5, and the base 1 is movably connected with the central shaft 4 through a central rod interspersed in the central shaft 4; The head of the central axis 4 is evenly provided with six wing mounting parts 4-1; the base 1 is evenly provided with six wingspans 1-1, and each wingspan 1-1 is provided with a wing at the head. Expand screw holes 1-2;

[0024] The wing 3 includes a connecting part 3-1 and a rotating part 3-2, and an included angle a of 120° to 150° is formed between the rotating part 3-2 and the connecting part 3-1; The connecting parts 3-1 of the six wings 3 are respectively fixedly connected with the corresponding wing mounting parts 4-1, and the bottom of the rotating part 3-2 of the wings 3 is provided with wing screw holes 3-3;

[0025] The connection block 2 includes a connection part 2-1 and a connection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com