Rectangular flange plate overturning system

A flanged and rectangular technology, applied in the field of rectangular flanged flipping systems, can solve the problems of high flipping costs, unprofessionalism, and many steps, and achieve the effect of eliminating manual operations and eliminating potential safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

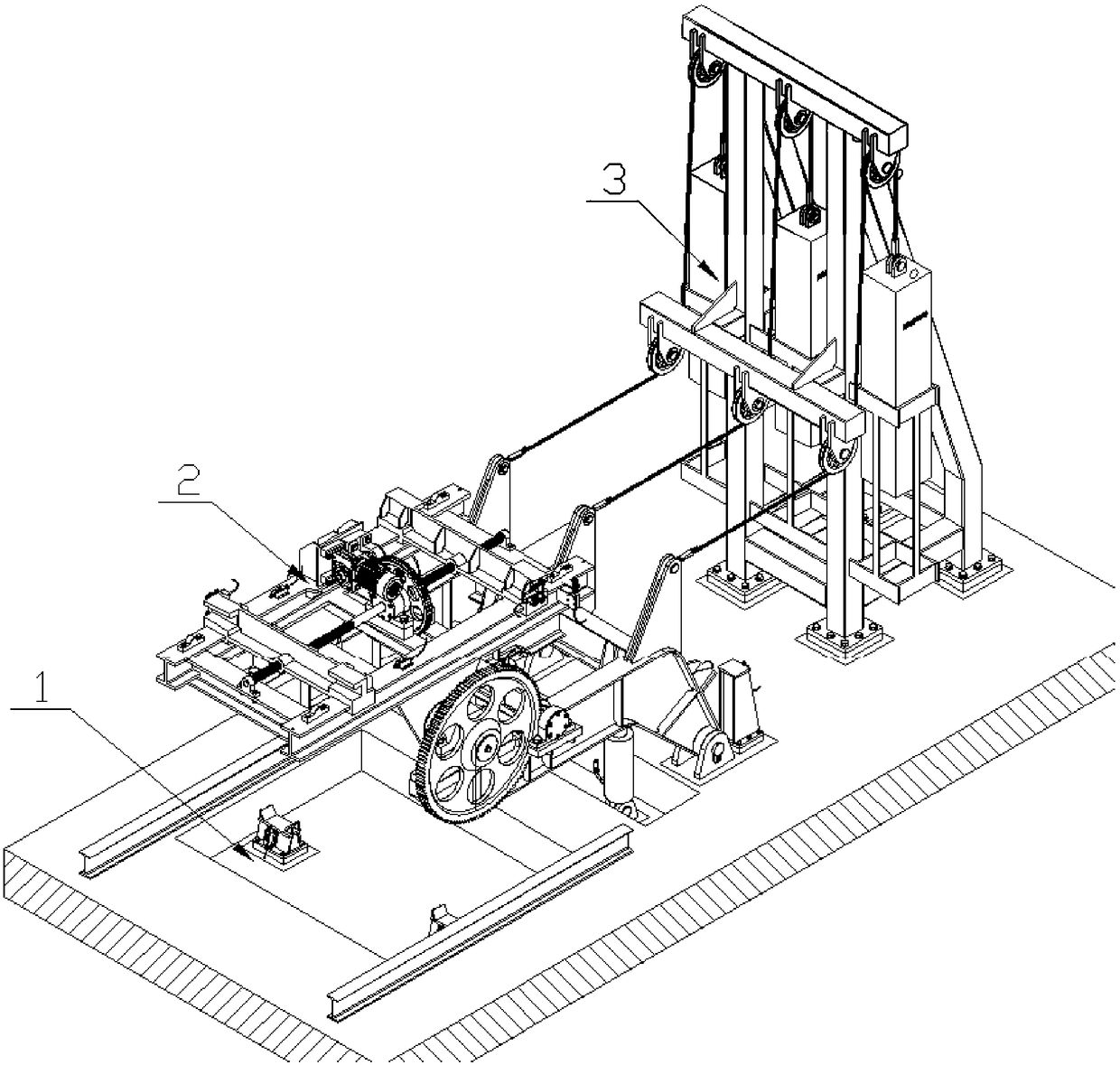

[0042] Please combine figure 1 As shown, a rectangular flange plate turnover system provided by the present invention includes: a base assembly 1 , a rotating assembly 2 and a balance assembly 3 arranged on the base assembly 1 .

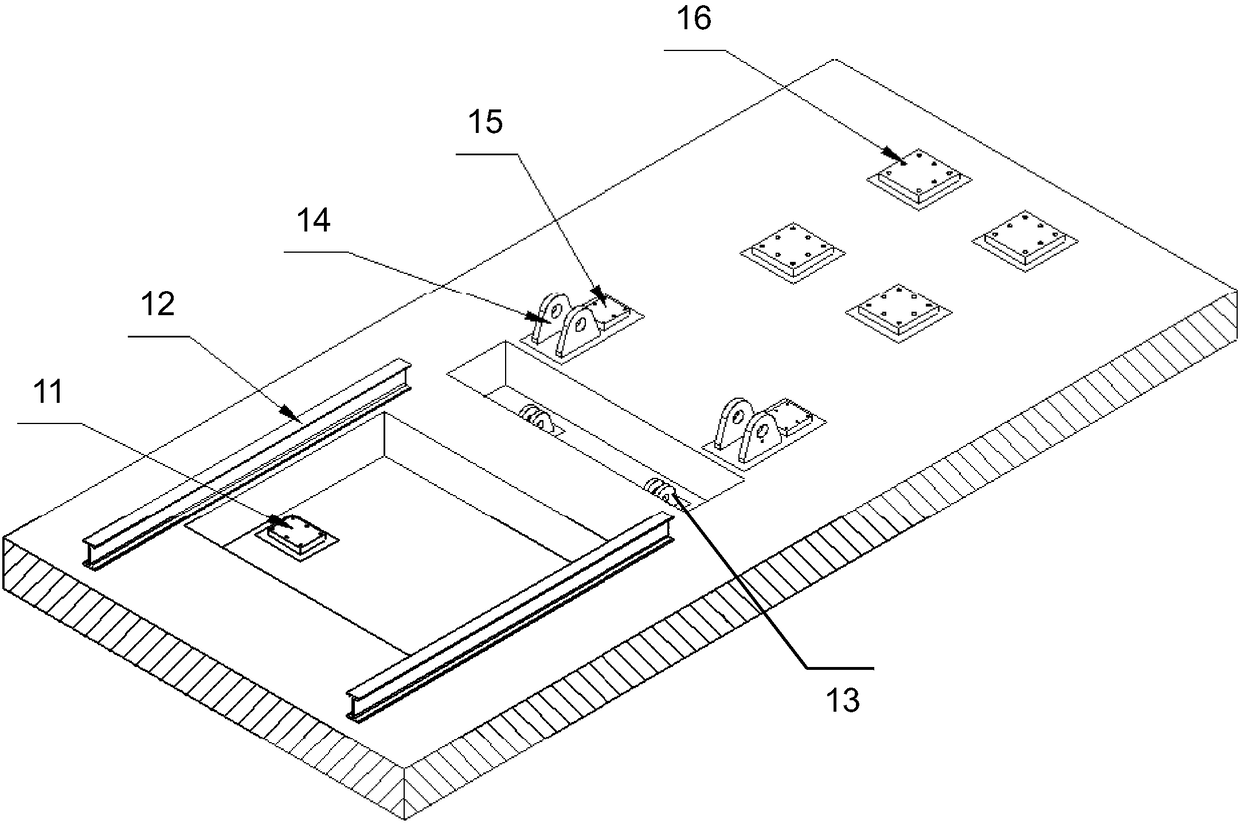

[0043] Please combine figure 2 As shown, the base assembly 1 is provided with a mounting flange 11 for a lifting device shelving seat, a flange plate shelving frame 12, a hydraulic cylinder mounting seat 13, a turning mechanism mounting seat 14, a limit pile mounting flange 15 and a balance mounting flange 16. The base assembly 1 has two functions: one, the flange plate shelf 12 is used to carry the flange plate to be turned over, or the flange plate that has been turned over; The function of the mounting seat is to install the rotating assembly 2 and the balancing assembly 3 .

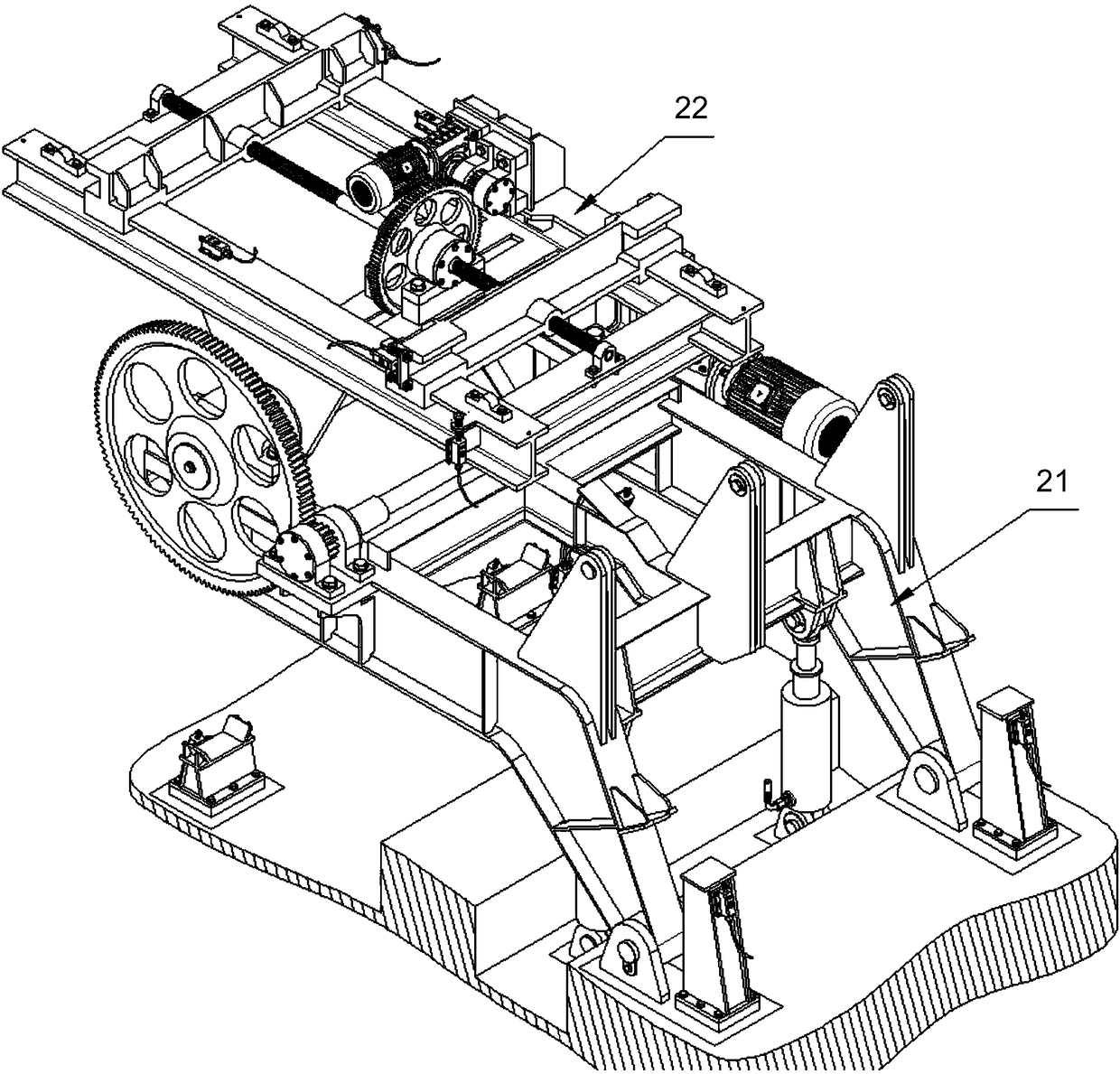

[0044] Please c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com