Portable pneumatic paint rolling brush

A pneumatic and paint technology, applied in the direction of coating, liquid coating device on the surface, etc., can solve the problems of pollution, paint dripping, etc., and achieve the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

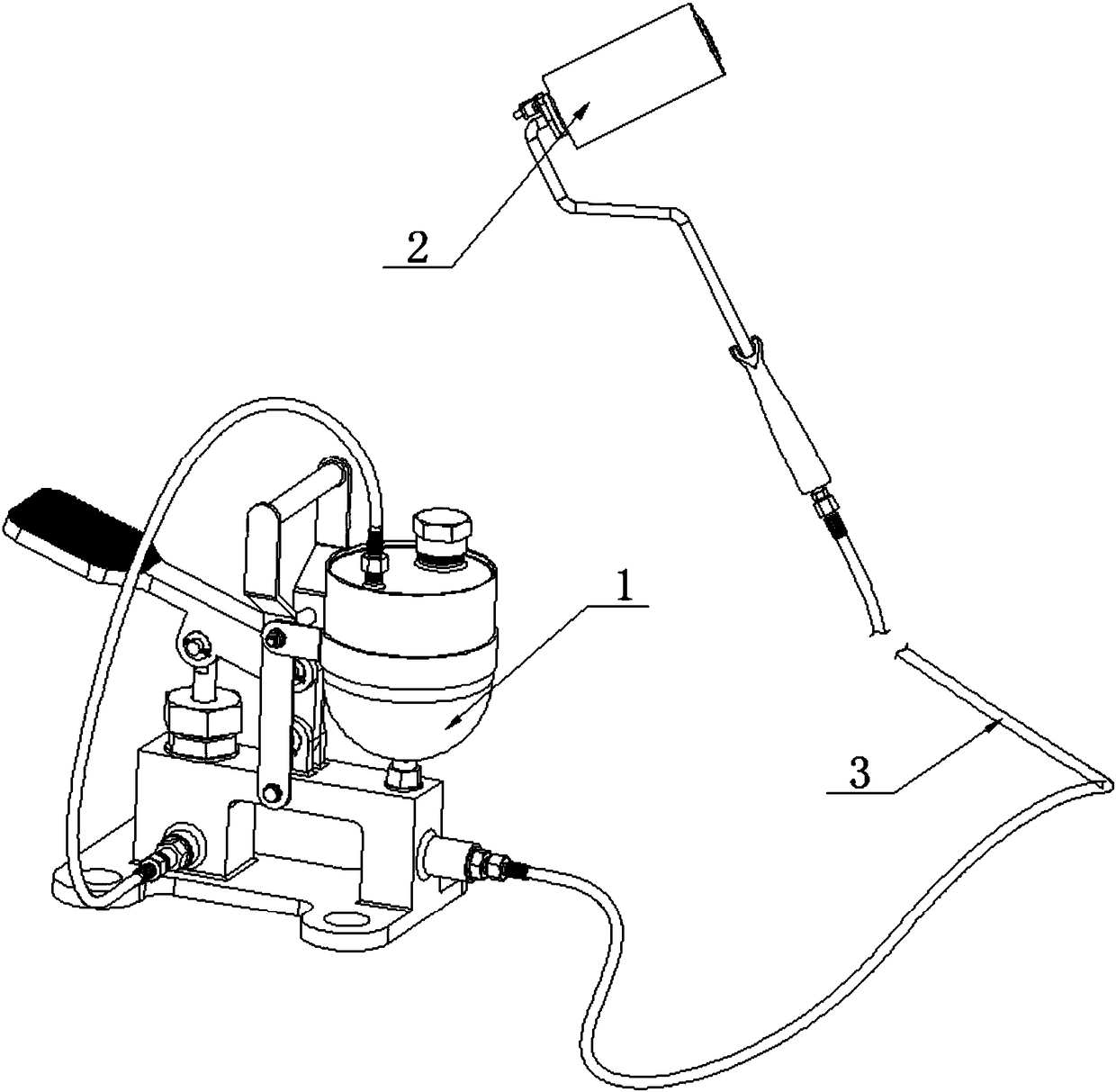

[0038] Please combine figure 1 As shown, a portable pneumatic paint roller brush provided by the present invention includes: an air compression device 1 , and a roller brush device 2 connected to the air compression device 1 through a paint delivery pipe 3 . The compressed air is generated by the air compression device 1, and the paint in the oil storage tank 12 is transported to the roller brush device 2 by using the expansion pressure of the compressed air, and then the paint in the roller brush core 221 penetrates into the roller brush through the oil seepage hole 223 Fabric 222 in.

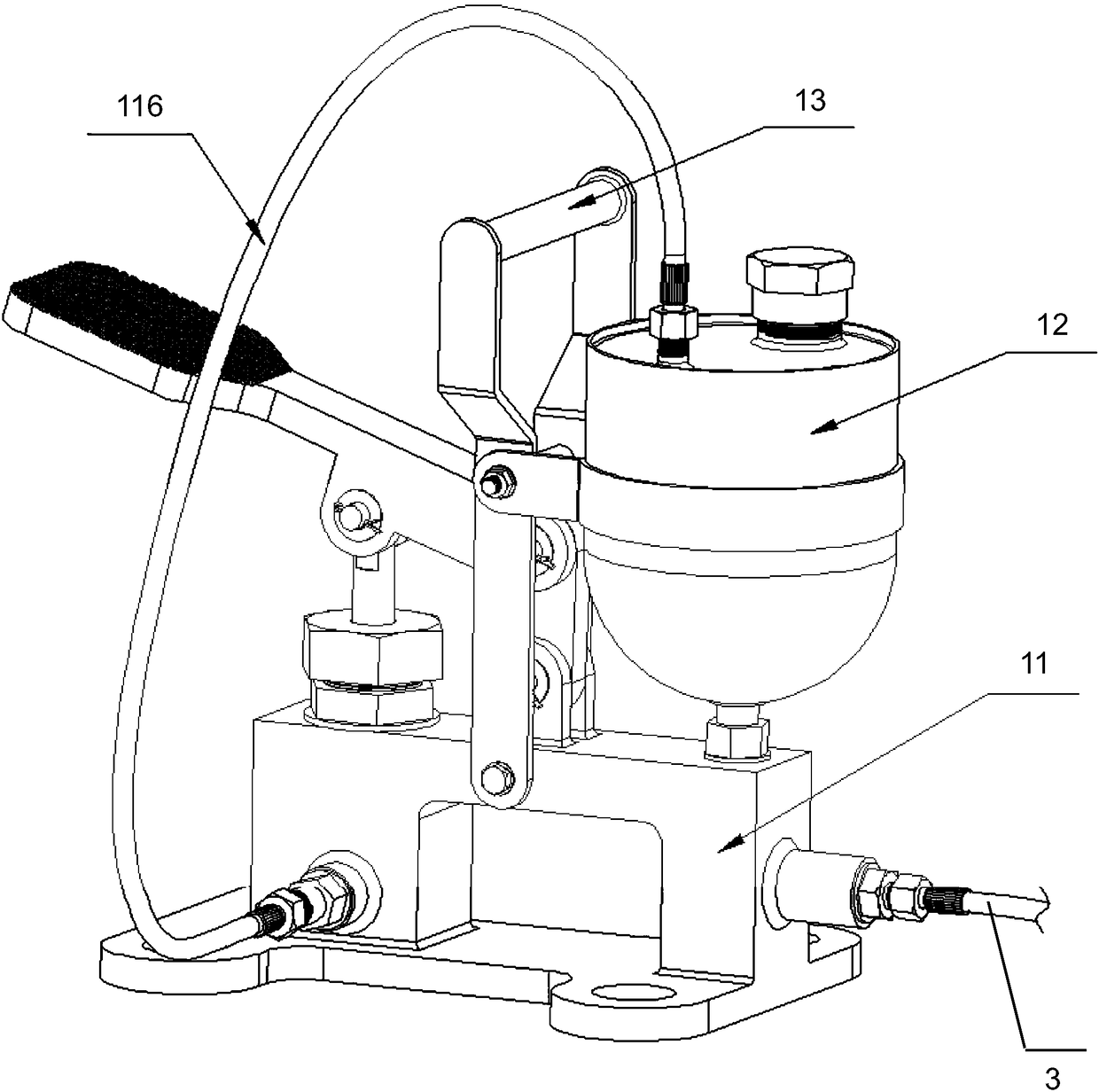

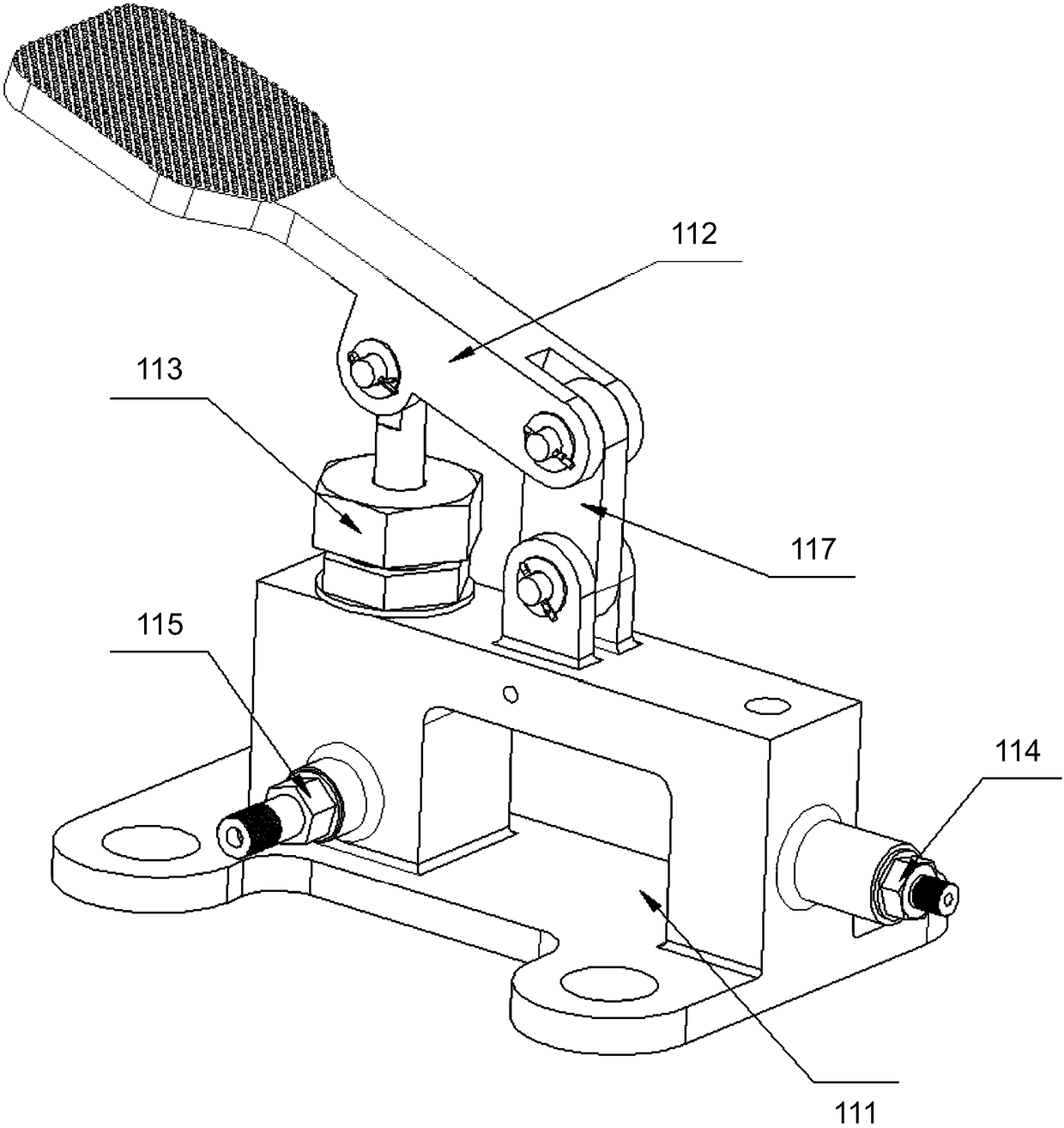

[0039] Please combine figure 2 As shown, the air compression device 1 includes: an air compression mechanism 11 , an oil storage tank 12 and an oil storage tank fixing frame 13 , and the oil storage tank 12 is arranged on the air compressio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com