Fuel gas mold temperature controller

A technology of mold temperature control and gas, which is applied in heat storage heaters, fluid heaters, lighting and heating equipment, etc. It can solve the problems of water drops in explosion-proof boxes and affect the normal combustion of gas in explosion-proof boxes, and achieve the effect of improving the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

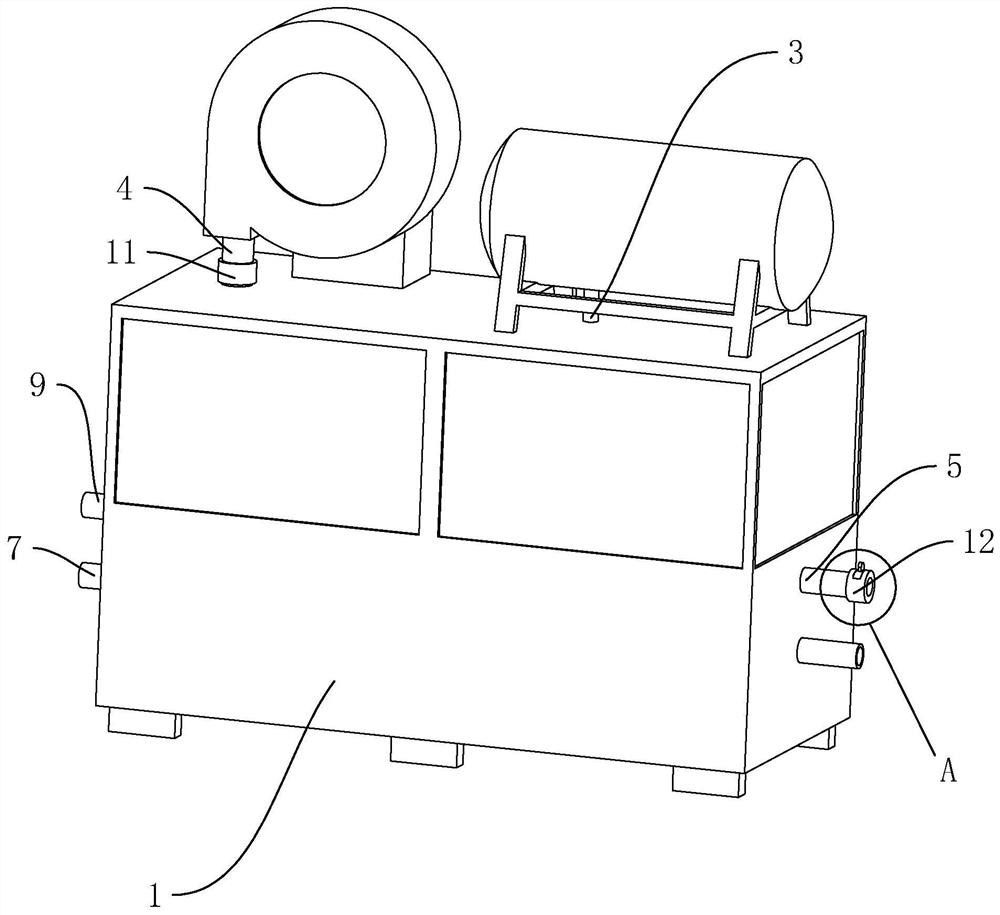

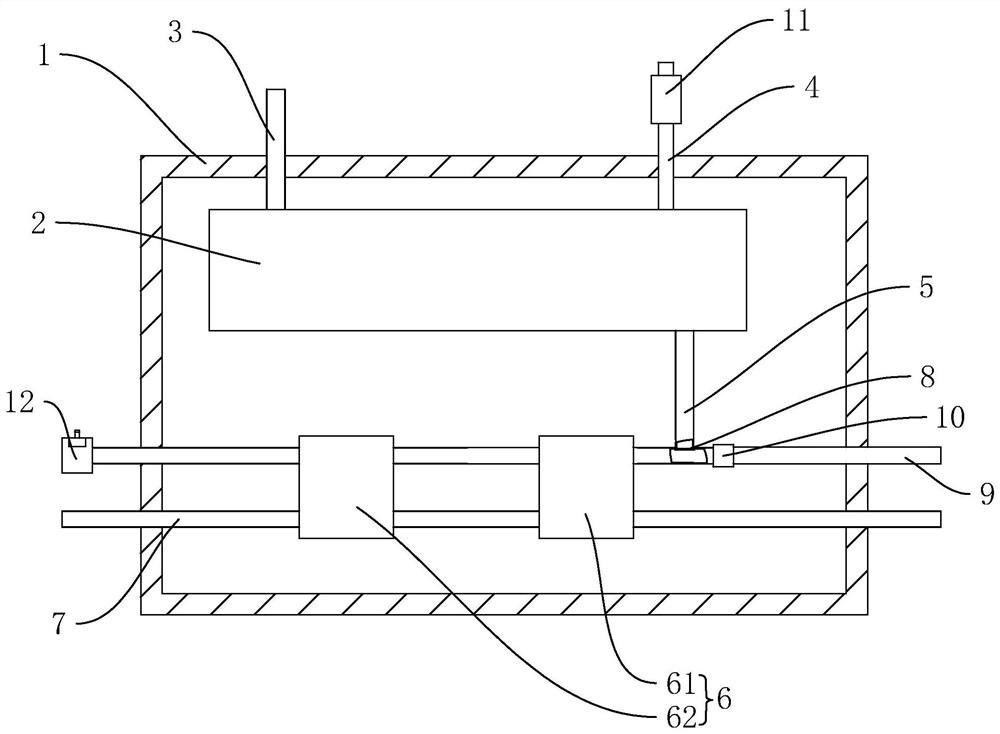

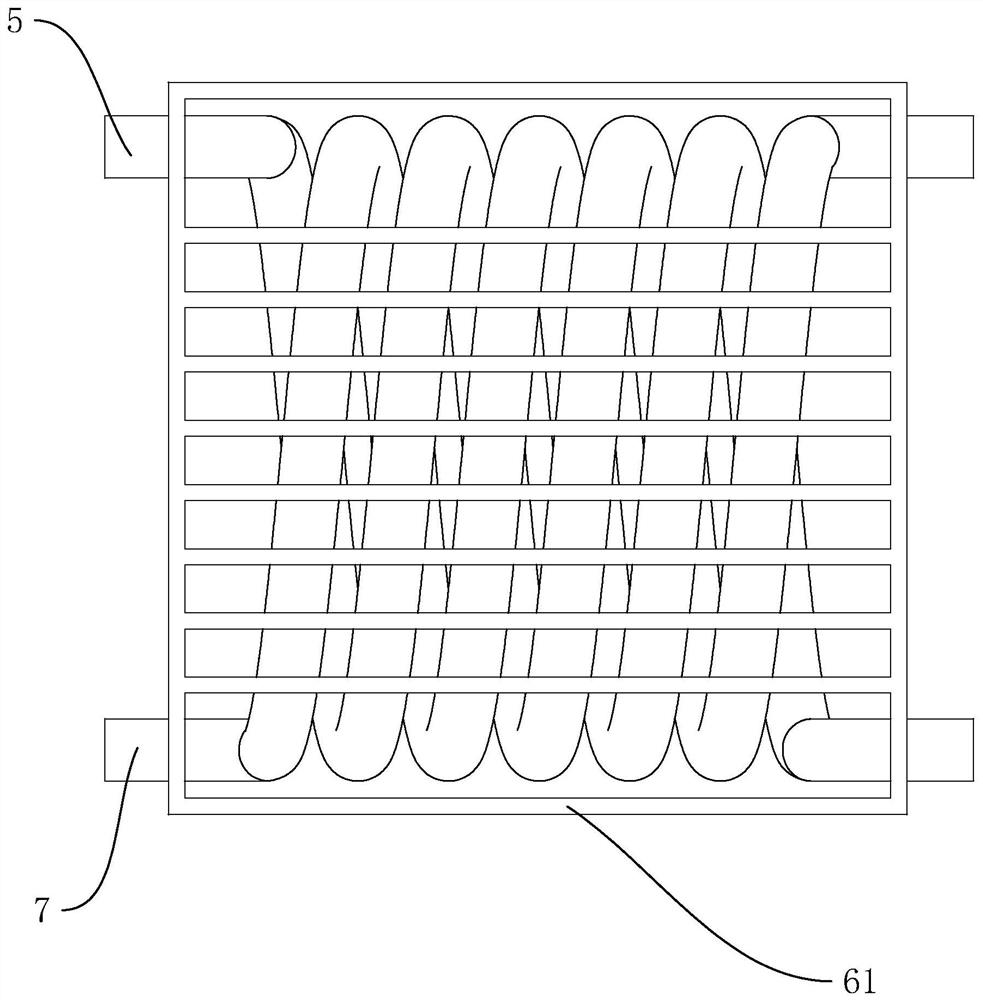

[0036] Attached to the following Figure 1-4 This application will be described in further detail.

[0037] The embodiment of the present application discloses a gas-fired mold temperature machine, refer to figure 1 and figure 2 , including the body 1, the body 1 is provided with a combustion chamber 2, the combustion chamber 2 is provided with an ignition device, the ignition device is used to ignite the gas, the combustion chamber 2 is connected with a gas pipe 3 and an air pipe 4, the gas pipe 3 and the air pipe 4 are connected to the combustion chamber 2 and one end away from the combustion chamber 2 extends out of the body 1, the gas pipe 3 extends out of the body 1 and one end is connected to the gas bottle, and the combustion chamber 2 is continuously supplied with gas through the gas bottle, and the air pipe 4 is connected to the outside of the body 1. 2. Provide the air required for combustion. A temperature sensor is installed in the combustion chamber 2. The temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com