Hot air circulation feeding integral device

A hot air circulation and integrated technology, which is applied in the direction of drying gas arrangement, drying solid materials, lighting and heating equipment, etc., can solve the problems of non-recycling of heat, high operating cost, and large fuel consumption, etc., to achieve convenient maintenance and extended use Life, the effect of accelerating the cooling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

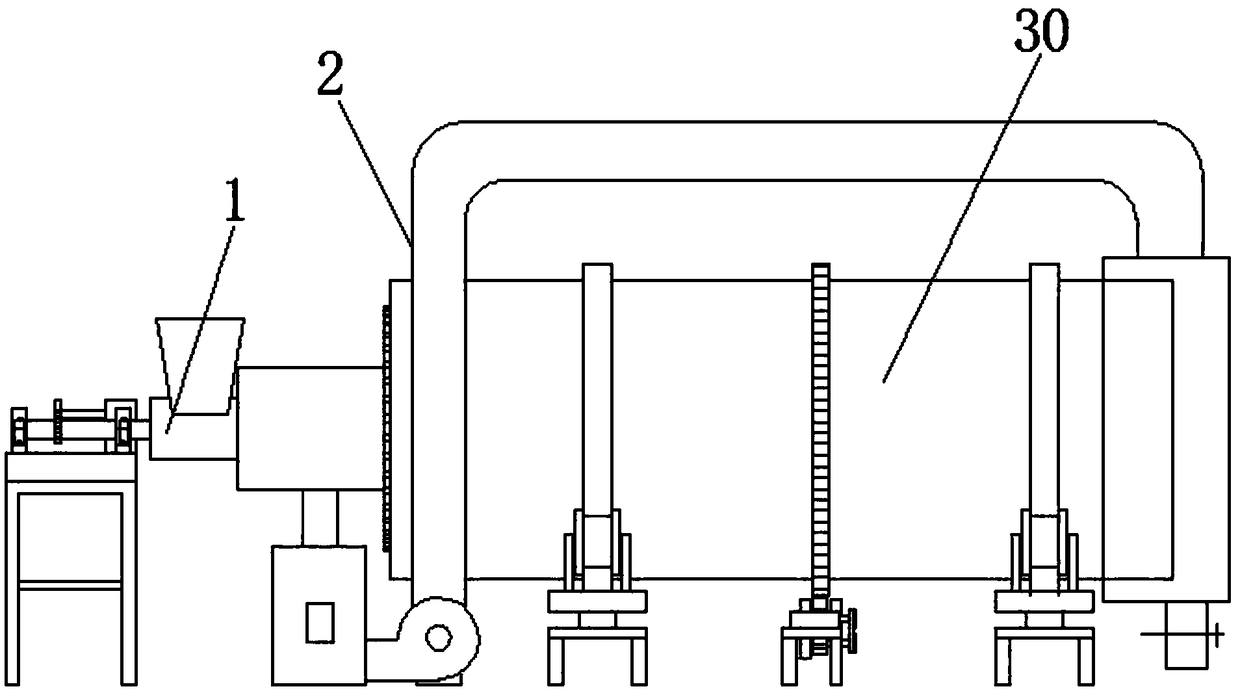

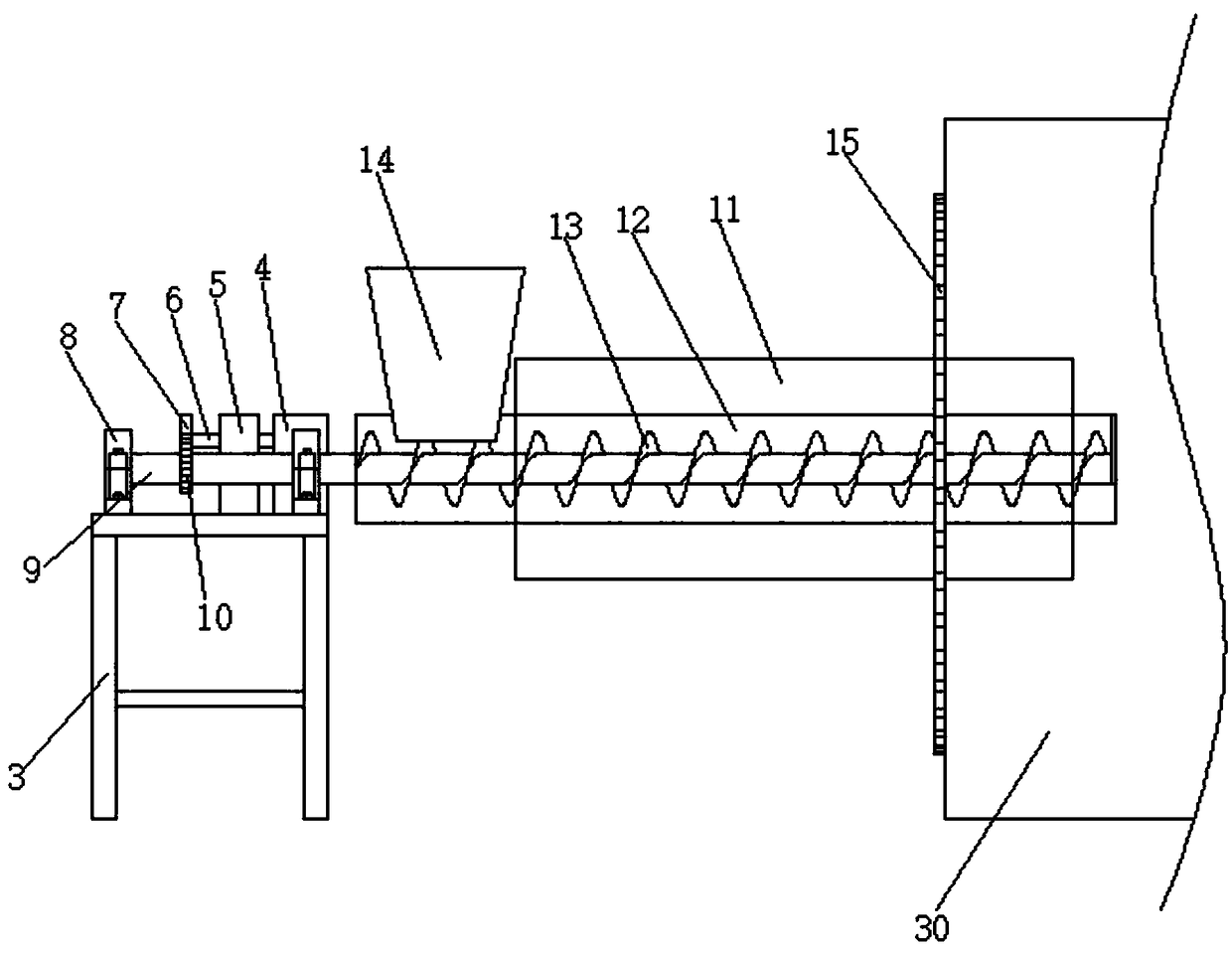

[0017] Attached below Figure 1-5 Shown is a further description of a hot air circulation feeding integrated device of the present invention.

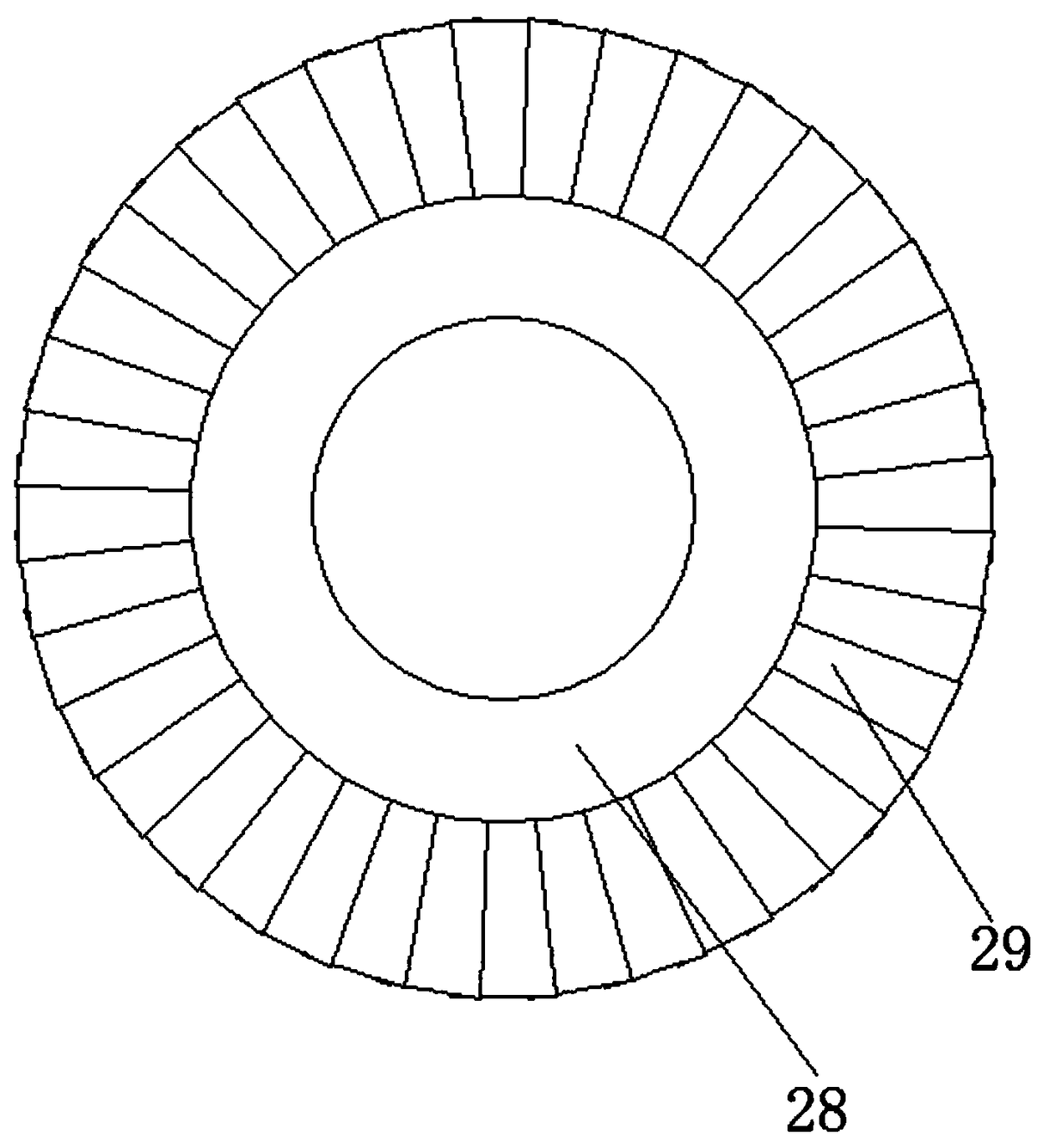

[0018] An integrated device for hot air circulation and feeding, including a feeding mechanism 1 and a hot air circulation mechanism 2, characterized in that: the feeding mechanism 1 includes a bracket 3, a preheating chamber 11, and a motor 4 is provided on the upper right side of the bracket 3, The left side of the motor 4 is provided with a speed reducer 5, the output end of the motor 4 is connected with the speed reducer 5, the first rotating shaft 6 is arranged for rotation in the speed reducing device 5, and the left end of the first rotating shaft 6 is connected with a driving gear 7, and the preheating chamber The position on the right side of 11 is provided with a shielding mechanism 15. The shielding mechanism 15 includes a fixed ring 28 fixed on the outer periphery of the preheating chamber 11. The outer periphery of the fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com