An Intelligent Control System of Dry Slag Cooling Air Volume

An intelligent control system and cooling air volume technology, applied in lighting and heating equipment, etc., can solve problems such as rising exhaust gas temperature, large slag volume changes, and inability to adjust cooling air volume in real time to achieve effective cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

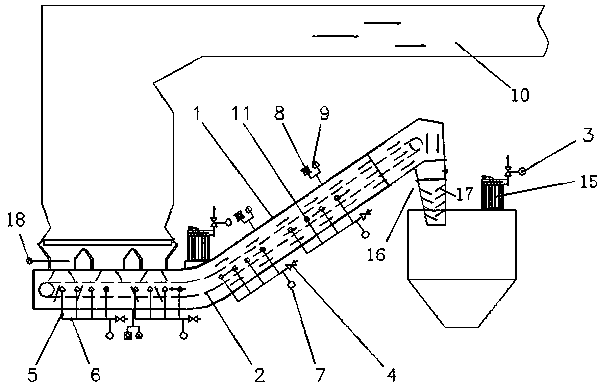

[0041] This embodiment introduces the intelligent control system of the dry slag cooling air for primary conveying:

[0042] The principle of the dry slag cooling air volume control system of the present invention is: calculating the cooling air volume entering the furnace according to the total furnace air inlet volume under different loads of the boiler, and this air volume is detected by a flowmeter located at the throat of the furnace; under this upper limit air volume condition, The air temperature of the steel belt machine head and the opening of the side air outlet valve are detected by the air thermometer, so that the ambient temperature of the head is in a reasonable range to ensure the safe and stable operation of the equipment. At the same time, according to the air volume at this time, the negative pressure of the bag filter in the slag silo or the opening degree of the connecting pipe with the tail flue is determined, and the excess cooling air is discharged.

[0...

Embodiment 2

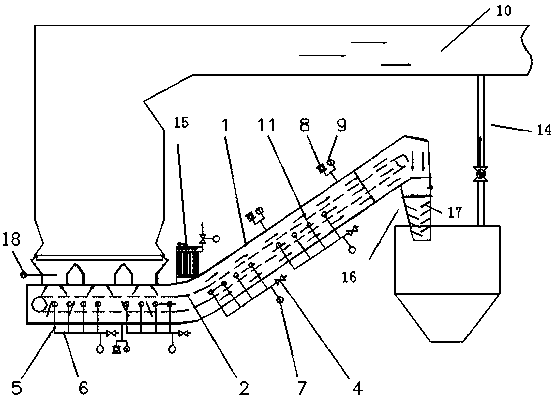

[0051] like figure 2 As shown, the slag bin can also be provided with an exhaust pipe 14, the exhaust pipe 14 is connected to the boiler tail flue 10, and the exhaust pipe 14 is provided with a valve that can adjust its opening, so that the The slag bin is connected to the boiler tail flue 10 through the exhaust pipe 14, and the negative pressure of the boiler tail flue 10 can be utilized to facilitate the suction of the dry slag cooling air in the steel belt machine.

Embodiment 3

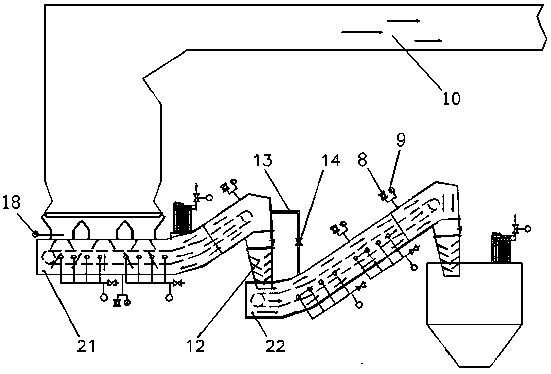

[0053] The secondary (including multi-stage) dry slag delivery system is slightly different from the primary dry slag delivery system. The tail of the secondary steel belt machine and the head of the primary steel belt machine are connected through a communication pipe. After the communication pipe is closed, the primary steel belt machine can be isolated from the subsequent steel belt machines. In this embodiment, the communication The pipe is the first communication pipe 12 .

[0054] like image 3 and Figure 4 As shown, the main body 1 of the steel belt conveyor of the secondary dry slag conveying system is designed as a primary conveying device 21 and a secondary conveying device 22 along the ash conveying direction. The first communication pipe 12 is connected to the tail of the secondary conveying device 22, the slag outlet is provided at the head of the secondary conveying device 22, and the air inlet of the primary conveying device 21 is provided at In the ash and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com