Battery cell with cell composite and manufacturing method thereof

A technology of battery cells and composites, applied in the directions of large-sized cells/battery packs, small-sized cells/battery packs, batteries, etc., can solve the problem of reducing the flammability of battery cells and increasing the cost and/or weight of battery systems And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

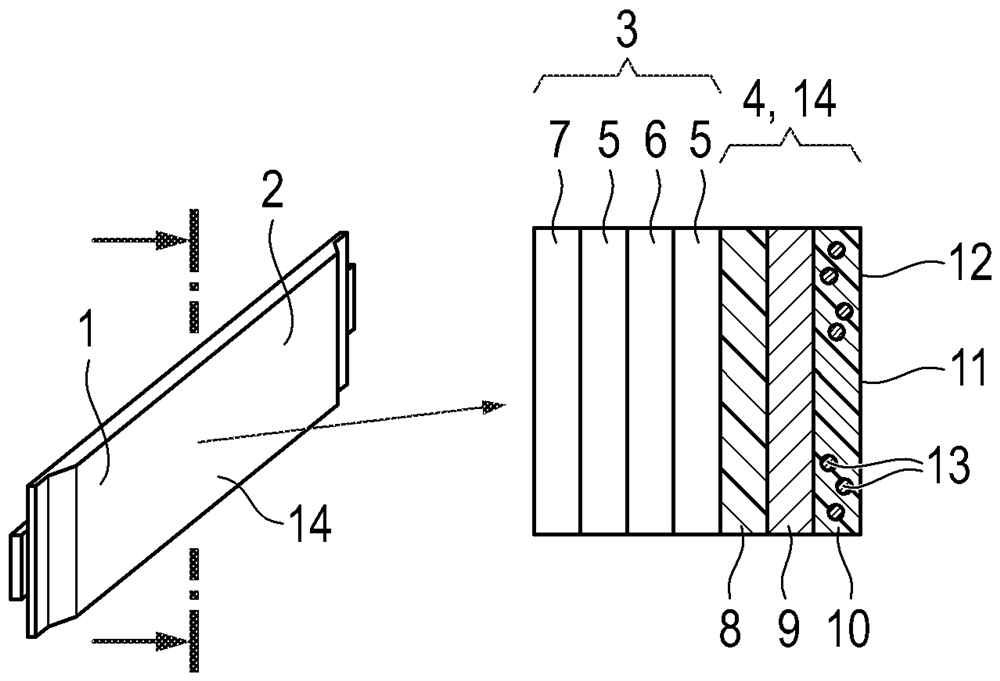

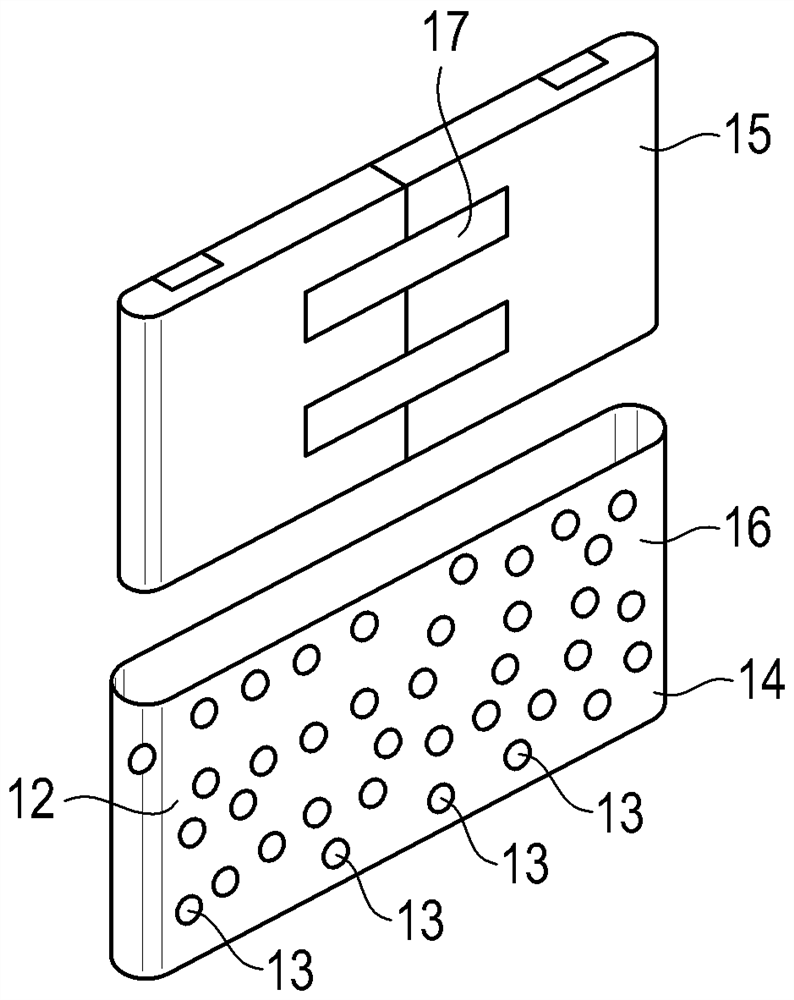

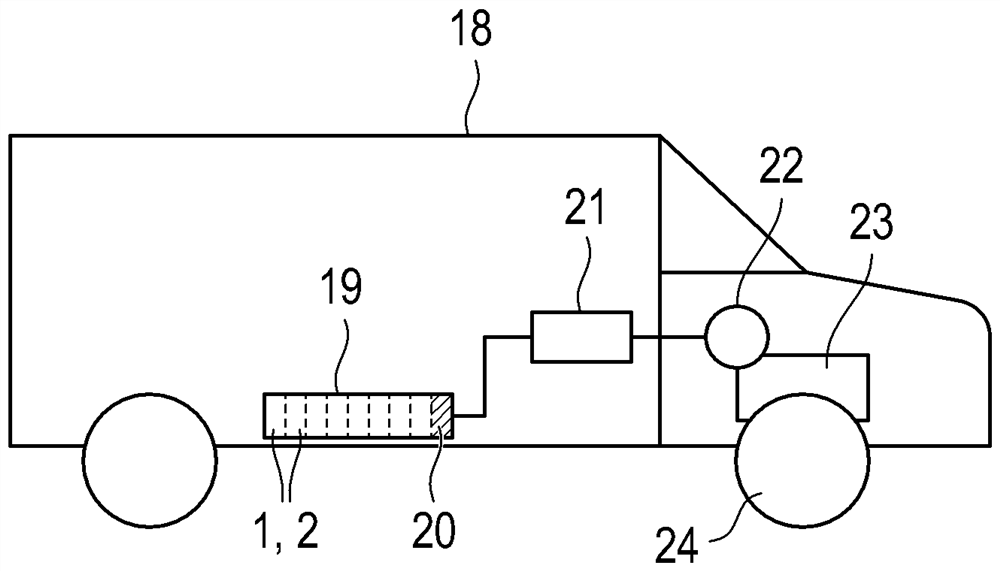

[0041] exist figure 1 , the battery cell 1 is shown in oblique view in the left region. The battery cells 1 are here formed as so-called pouch cells 2 . This means that the cell compound 3 is hermetically encapsulated by the soft envelope 4 . The cell composite 3 is constructed in multiple layers and has alternating layers of separators 5 , cathodes 6 and anodes 7 . In the embodiment shown, the soft envelope 4 itself has a three-layer structure. In this case, the inner first layer 8 is made of a polymer, eg polypropylene. The second layer 9 is a metal layer where aluminum or its alloys can be used. The third layer 10 of the soft envelope 4 forms the outer side 11 of the soft envelope 4 and at the same time forms the functional layer 12 . The functional layer 12 here provides improved flame resistance and contains a flame-retardant substance 13 for this purpose. In the state of complete assembly, the soft envelope 4 composed of one or more parts forms the casing 14, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com