Anticorrosion factory building wall plate and lap joint method thereof

A technology of anti-corrosion and wall panels, applied in building components, building insulation materials, buildings, etc., can solve the problems of construction difficulty and high cost, short service life, poor corrosion resistance, etc., and achieve reduced construction costs, long service life, The effect of simple construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0030] Example 1

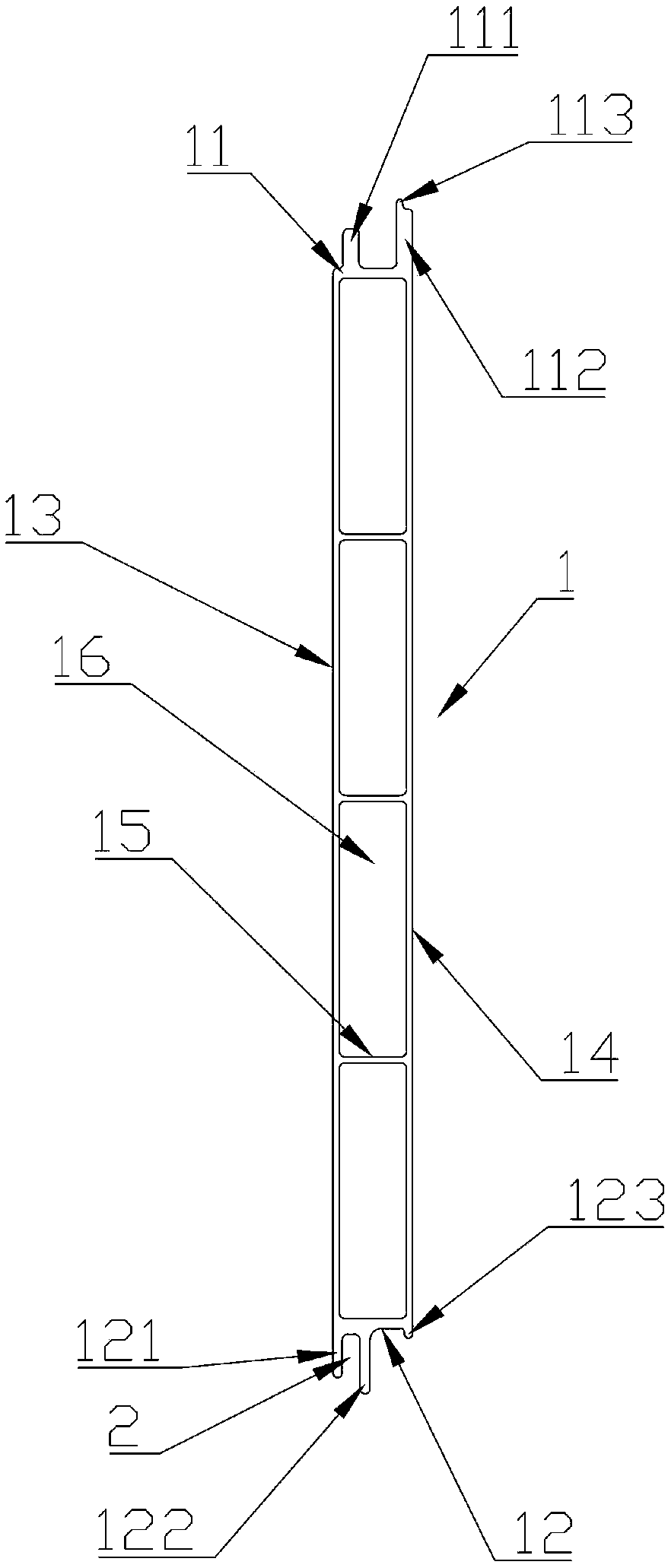

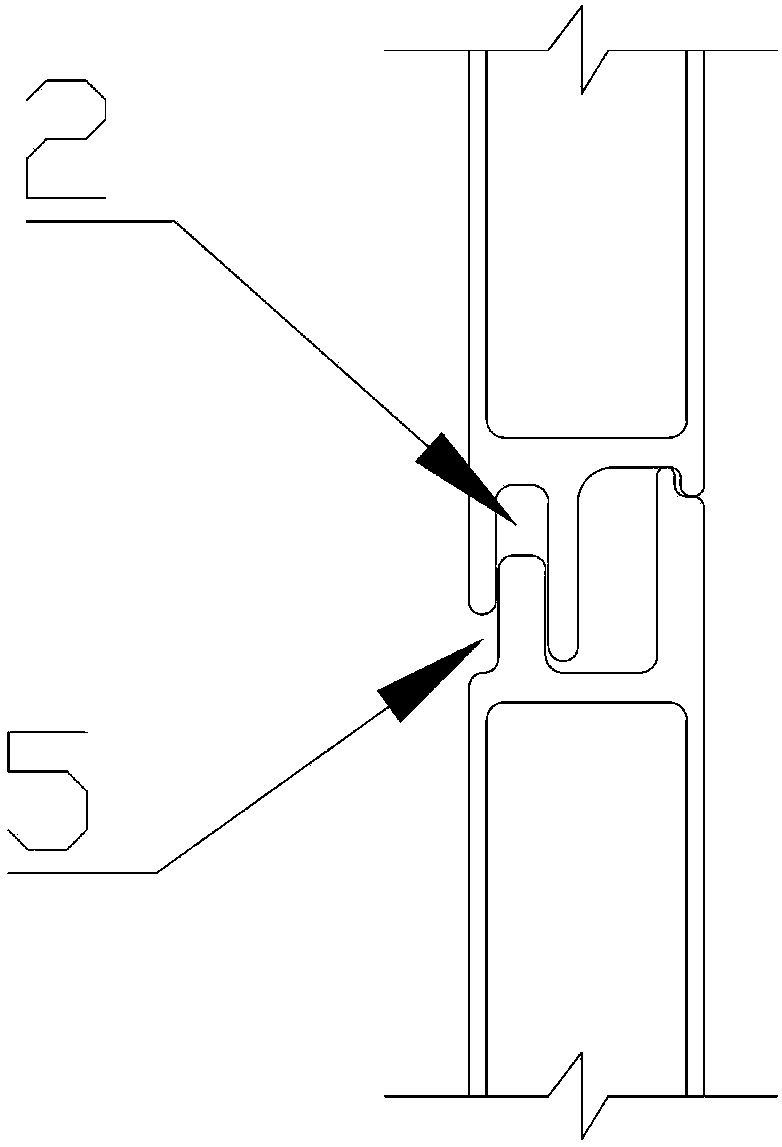

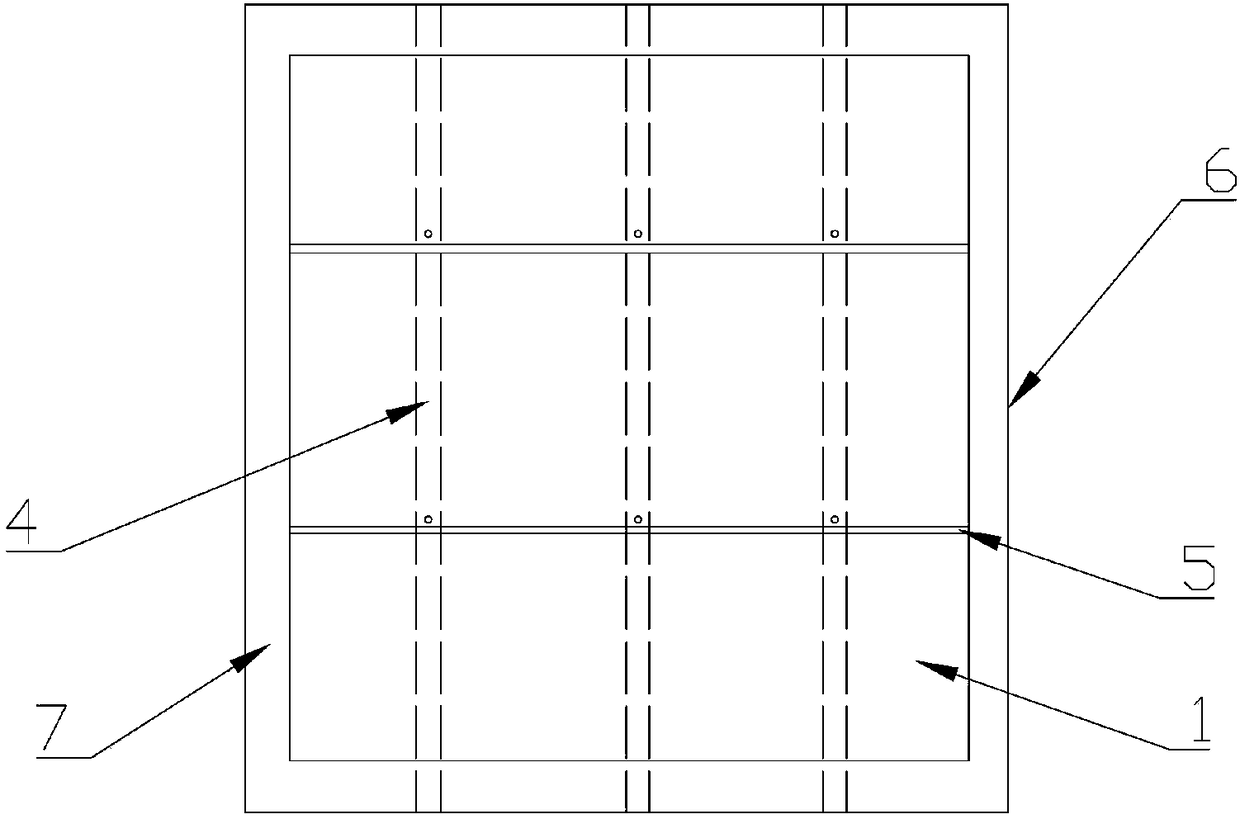

[0031] like figure 1 As shown, a kind of anti-corrosion plant wall panel proposed in this embodiment includes a wall panel main body 1, and the wall panel main body 1 includes a top plate 11 and a bottom plate 12 arranged in parallel and a first panel 13 connected between the top plate 11 and the bottom plate 12 And the second panel 14, when in use, the first panel 13 is facing the outside of the factory building, the second panel 14 is facing the inside of the factory building, and the top plate 11, the bottom plate 12, the first panel 13 and the second panel 14 are surrounded by a closed structure with a cavity inside , the cavity of the wallboard main body 1 is provided with a number of stiffeners 15, the cavity of the wallboard main body 1 is divided into several chambers 16 by several stiffeners 15, the strength is high, the structure is light, and it will be static The air is used as the insulation layer, which has a good thermal insulation function. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com