SMA (shape memory alloy) bar assembled self-resetting damper

A self-reset, prefabricated technology, applied in protective buildings/shelters, building types, buildings, etc., can solve the problems of small diameter of SMA wire, inconvenient installation and use, low yield force, etc., and achieve mechanical performance. Simple and clear, easy to install, the effect of high yield force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0056] method one:

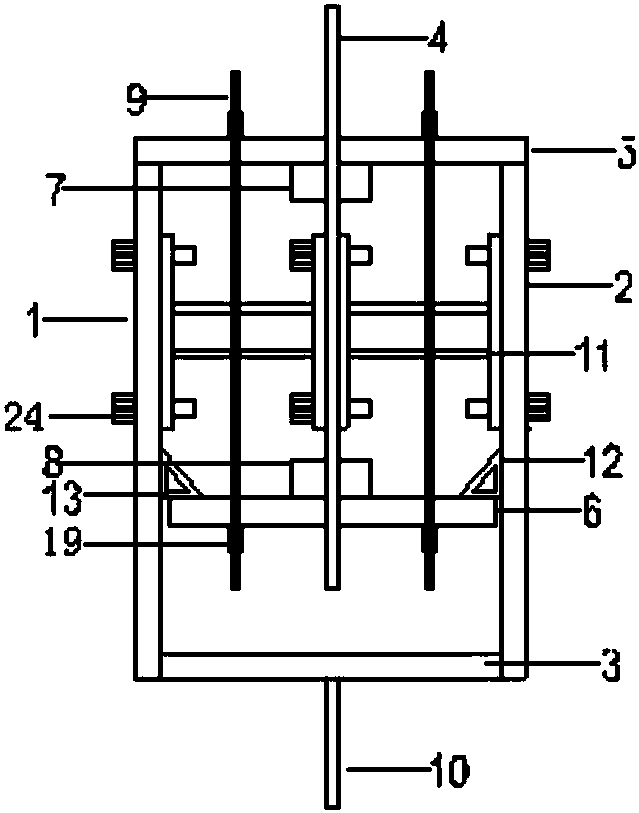

[0057] like Figure 7 As shown, the energy dissipating element 11 includes two opposite flange plates 20 and at least one web 21 arranged between the two flange plates 20, and a rhombus hole 22 is opened on the web 21, and the rhombus hole is used for the SMA rod through, and the diamond-shaped hole is larger than the cross-section of the SMA rod, to ensure the relative movement of the SMA rod and the energy-dissipating element when the SMA rod is pulled and the energy-dissipating element is deformed; yield.

[0058] Method 2:

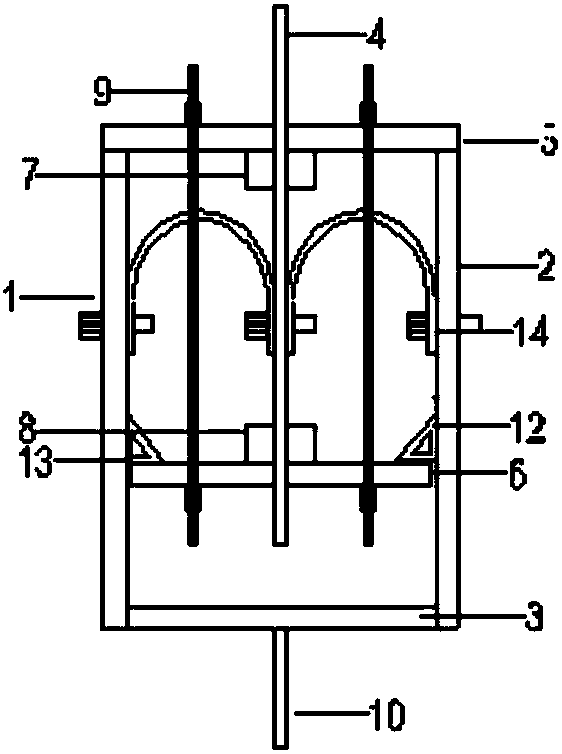

[0059] like Figure 8 As shown, the energy-dissipating element is a U-shaped steel plate 14, and the arc section of the U-shaped steel plate 14 is provided with a long hole 23 along the arc direction. The long hole ensures that the SMA rod and the energy-dissipating element relative movement.

[0060] The quantity of energy-dissipating elements 11 (or 14) can be set as required, preferably an even number, evenly distributed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com