Comprehensive vending machine

A vending machine and storage technology, which is applied to instruments, coin-operated equipment for distributing discrete items, coin-operated equipment for distributing discrete items, etc., can solve the problem of low space utilization, large thrust, and inability to achieve volume and other problems, to achieve the effect of simple structure, improved fluidity, and accurate control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

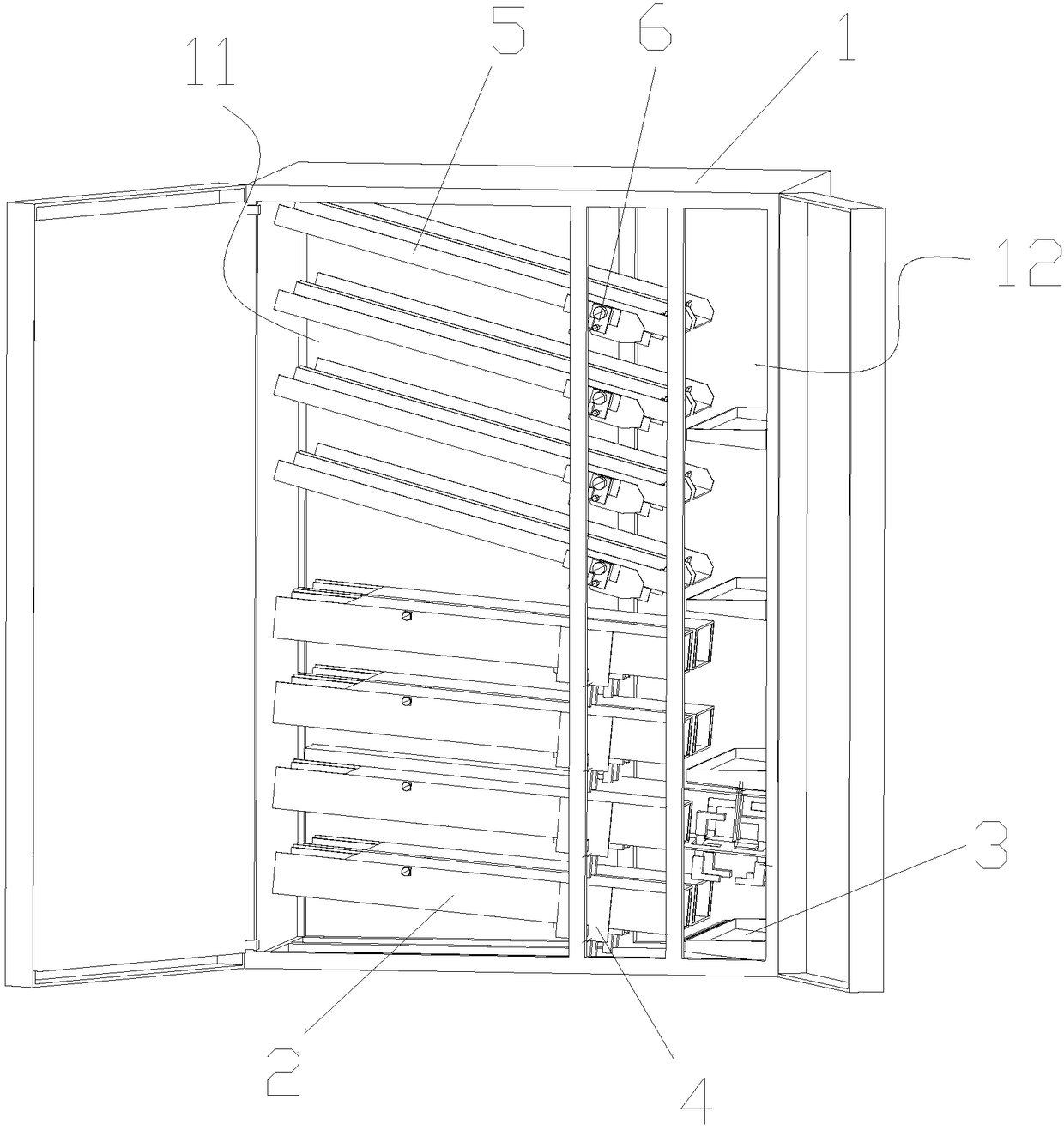

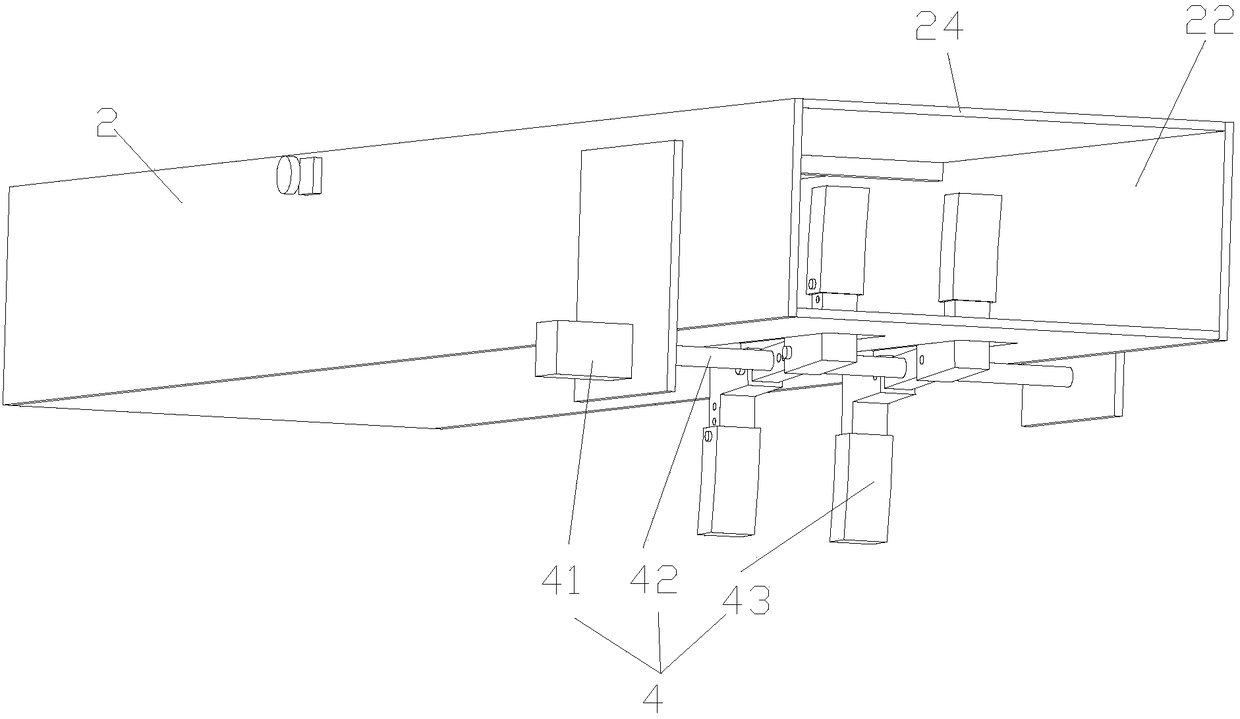

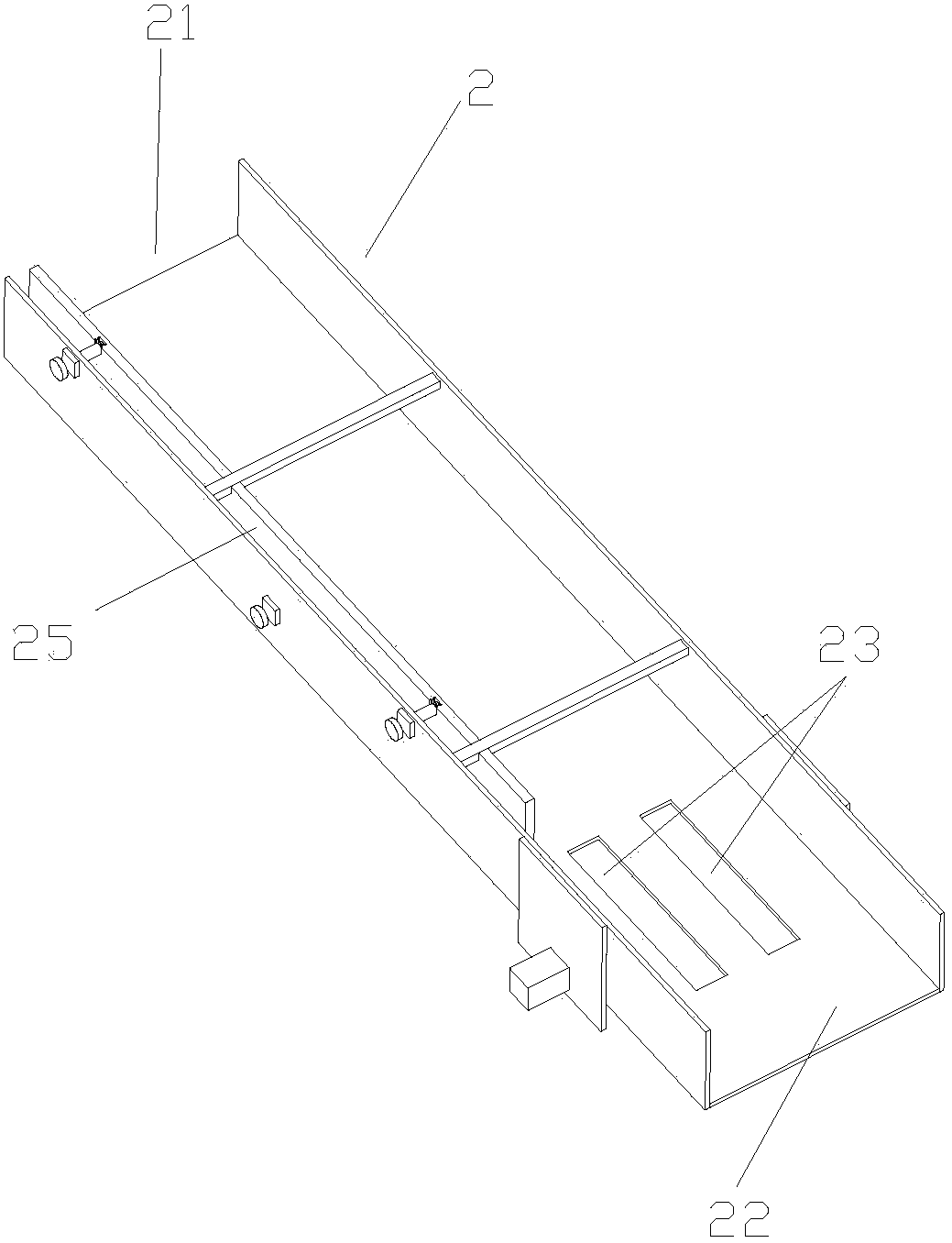

[0039] Embodiment 1: as Figure 1~6 As shown, a comprehensive automatic vending machine includes a box body 1, and the box body 1 is provided with a storage area 11 and a pick-up area 12; the storage area 11 is provided with at least one Inclined first storage tank 2; said picking area 12 is provided with at least one picking tank 3; the left end of said first storage tank 2 has a material inlet 21, and the right end has a material outlet 22; said The first control device 4 that can control the individual output of goods is provided on the first storage tank 2 near the discharge port 22; the first control device 4 includes a first drive device 41, a first rotating shaft 42 and at least one claw 43; the first driving device 41 is drivingly connected to the first rotating shaft 42; the claw 43 is sleeved on the first rotating shaft 42; the claw 43 includes at least two uniformly distributed around the center of the first rotating shaft 42 Clip bar 431 ; the first space-avoiding...

Embodiment 2

[0043] Embodiment 2: In embodiment 1, such as Figure 7 As shown, two limiting parts 431-2 of the clamping strip 431 are provided, the two limiting parts 431-2 and the vertical part 431-1 form a "T" shaped clamping strip, and the two clamping strips form an "H" shape Claws, the goods limiting part 431-2 can be provided with a certain arc, so that the movement is more stable after contact with the goods; after the goods fall, they will enter the vertical part 431-1 of the two clamping bars 431, and pass through the two limiting parts 431-2 is engaged and fixed, and as the first rotating shaft 42 drives the claw 43 to rotate, the claw 43 drives the cargo to be transported, and the next cargo will be blocked due to the turning in of the limiting part 431-2 , the vertical part 431-1 can only be entered and engaged after the limiting part 431-2 is disengaged. At this time, the previous cargo has been transported to the other side by the claw 43 and dropped into the cargo picking gr...

Embodiment 3

[0045] Embodiment 3: as Figure 9 As shown, in the structure of Embodiment 1, three clamping strips 431 are set; the shape of the clamping strips 431 is a vertical strip shape, and the three clamping strips 431 form a "Y"-shaped claw 43, and every two The angle between the two clamping strips 431 is 120°, and the goods are engaged between the two clamping strips 431 to be transported. The first rotating shaft 42 takes out one cargo every 120° rotation, and three cargoes are brought out in one revolution.

[0046] Such as Figure 10 As shown, the clip bar 431 is sleeved with a first connecting piece 432 slidably connected thereto; by adjusting the position of the first connecting piece 432 on the clip bar 431 , it can adapt to goods of different specifications.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com