Insulation cleaning agent electrified cleaning method for 500 kV electric transmission line tension insulator string

A technology for tensile insulator strings and transmission lines, which is applied in the directions of cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., can solve the problem of no 500kV transmission line tensile insulator strings insulation cleaning agent electrified cleaning, etc. Achieve good economic and social benefits, reduce line power outages, and ensure safety and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

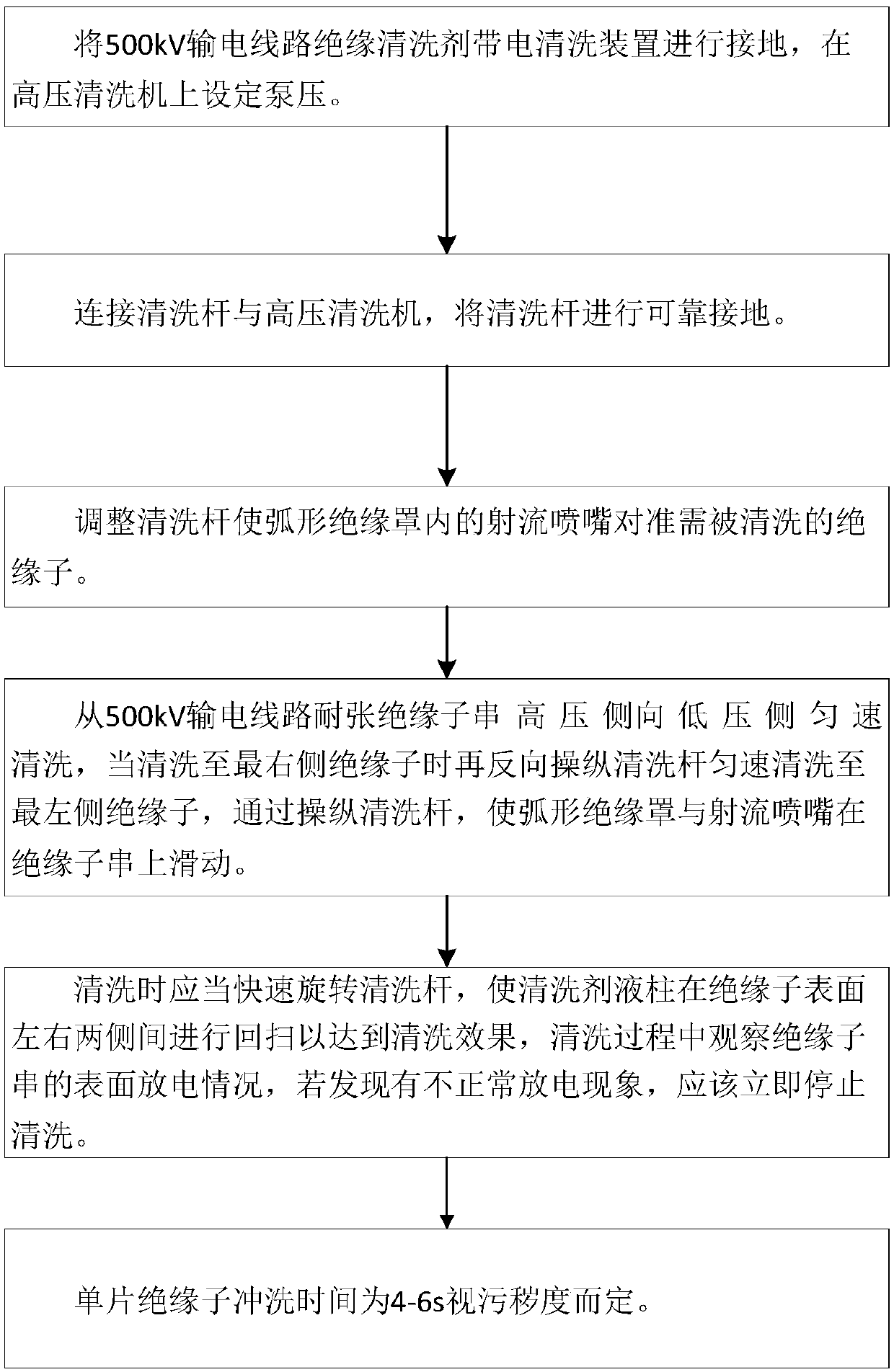

[0022] This embodiment is realized by the following method, a 500kV transmission line tension insulator string insulation cleaning method charged cleaning method, including the following steps:

[0023] Step a: Ground the 500kV transmission line insulation cleaning agent live cleaning device, and set the pump pressure on the high-pressure cleaning machine.

[0024] Step b: Connect the cleaning rod to the high-pressure cleaner, and reliably ground the cleaning rod.

[0025] Step c: Adjust the cleaning rod so that the jet nozzle in the arc-shaped insulating cover is aimed at the insulator to be cleaned.

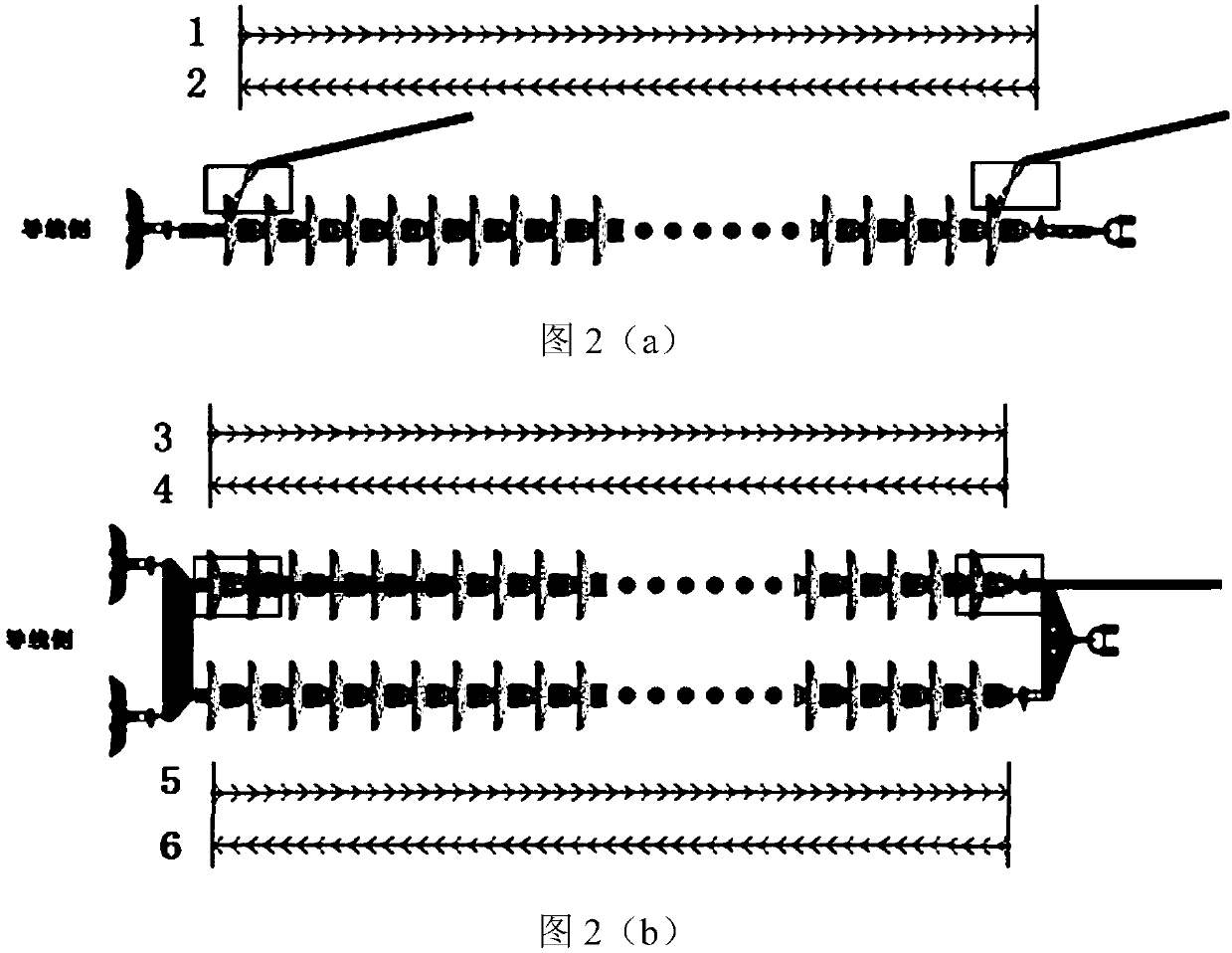

[0026] Step d: Clean at a constant speed from the high-voltage side to the low-voltage side of the tension insulator string of the 500kV transmission line. The shroud and jet nozzle slide over the string of insulators.

[0027] Step e: When cleaning,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com