Turbine oil pipeline pure water cleaning system

A steam turbine oil and cleaning system technology, applied in the field of oil pipeline cleaning, can solve the problems of insignificant cleaning effect, secondary pollution, labor and time-consuming, etc., and achieve significant economic value and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

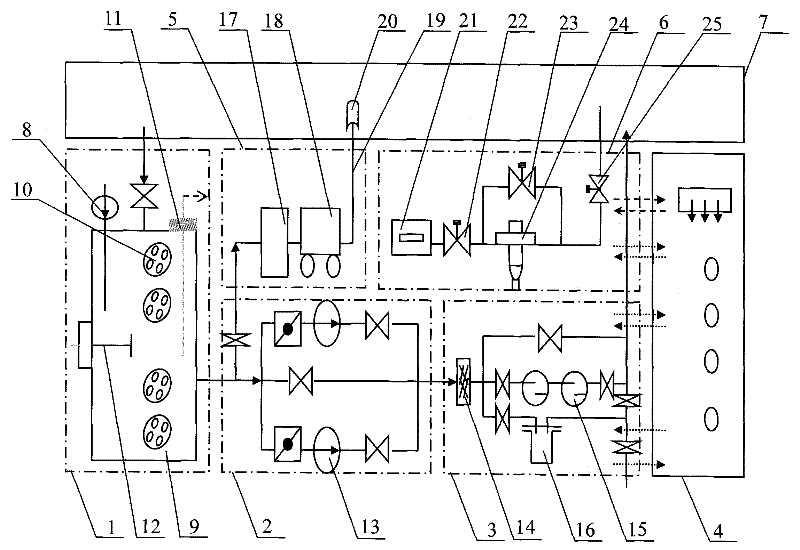

[0017] As shown in the drawings, the present invention consists of a pure water cleaning liquid preparation subsystem 1, a large flow cleaning subsystem 2, a quality purification subsystem 3, a cleaning regulation subsystem 4, a high-pressure cleaning subsystem 5 and a compressed air purging subsystem 6 constitute.

[0018] in:

[0019] The pure water cleaning solution preparation subsystem 1 includes: a self-priming pump 8 , a preparation box 9 , a combined heating tube 10 , a contact temperature sensor 11 , and a stirrer 12 .

[0020] The large-flow cleaning subsystem 2 includes: a dual-combination large-flow multi-suction cleaning pump station 13 .

[0021] The quality purification subsystem 3 includes: a strong magnetic filter 14 , a particle filter (two groups are shown in the figure) 15 , and a quality improvement processing filter 16 .

[0022] The cleaning control subsystem 4 includes: a temperature control subsystem, a pressure control subsystem, a flow control sub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com