Carpet Automatic Unwinding Machine

A technology of unwinding machine and carpet, which is applied in the direction of winding strips, binding materials, thin material processing, etc. It can solve the problems of time-consuming, laborious and low work efficiency, and achieve the effects of not being loose, easy to operate, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

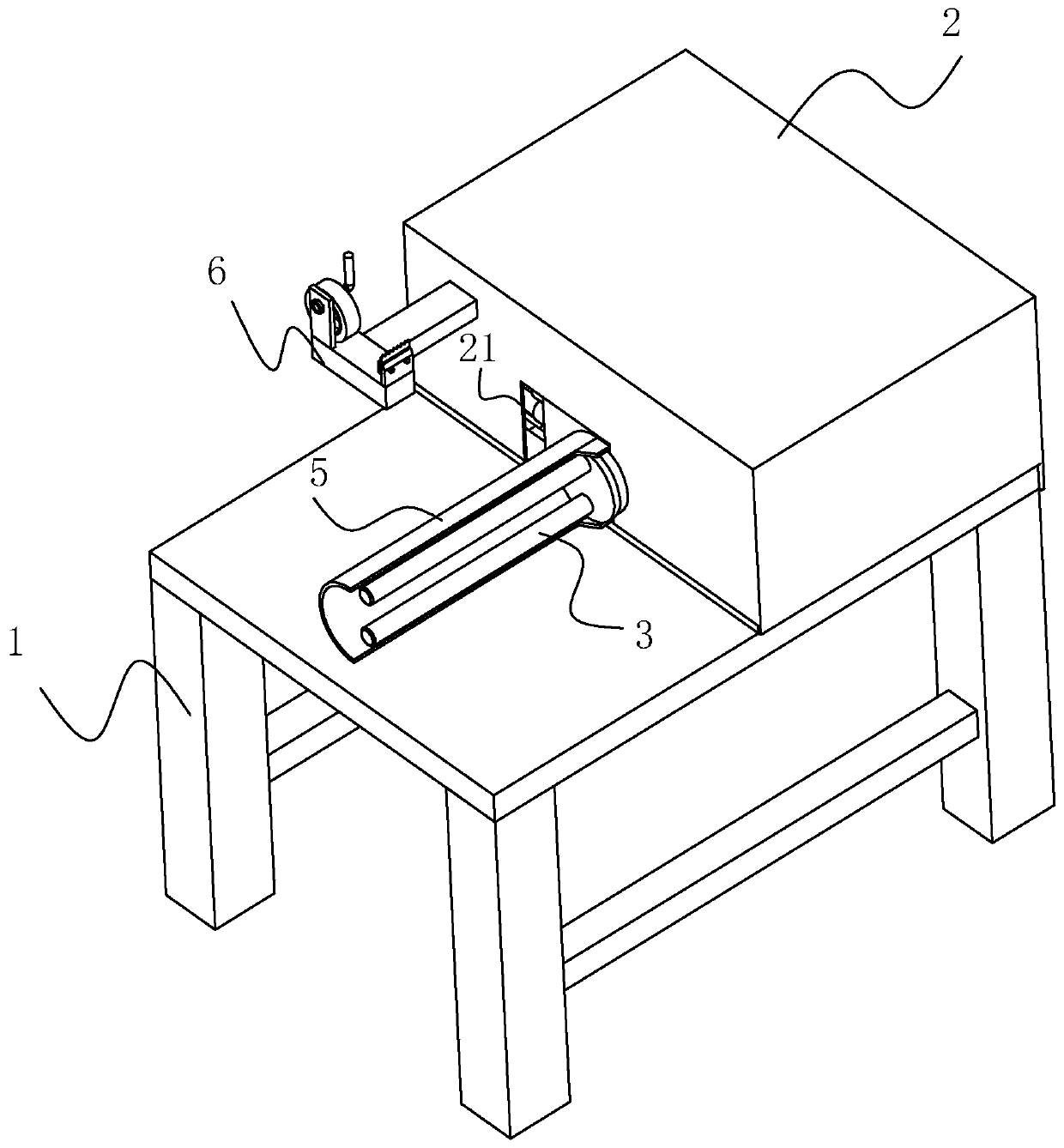

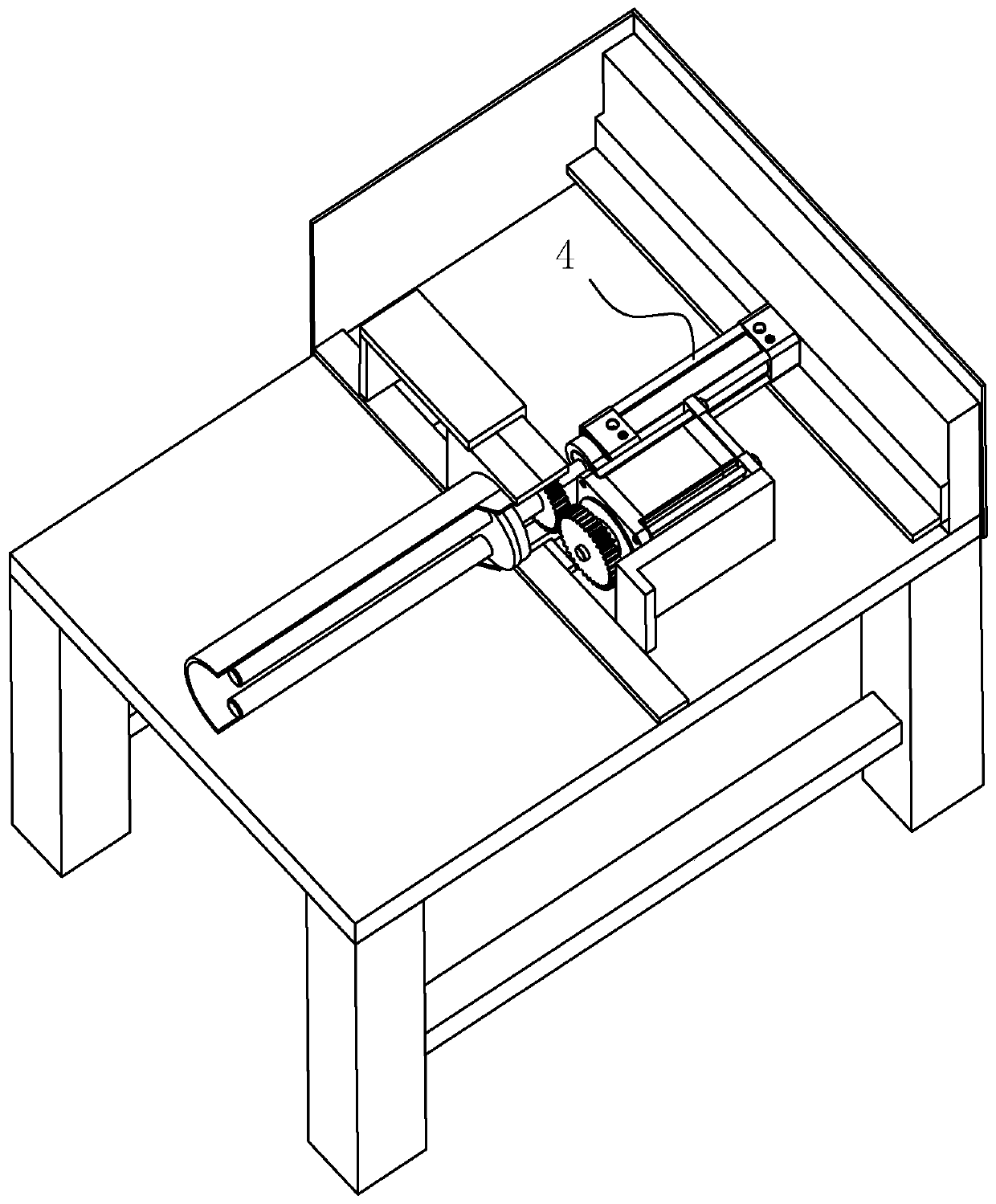

[0036] Embodiment: a kind of automatic carpet unwinding machine, see figure 1 and figure 2 , including a frame body 1, a cover body 2 on the frame body 1, a curling device 3 on the frame body 1, an unrolling device 4 inside the cover body 2, a telescopic member 5 on one side of the cover body 2 and a Packing device 6 on body 2. A rectangular hole 21 is opened on the cover body 2 , and the telescopic member 5 can expand and contract in the rectangular hole 21 .

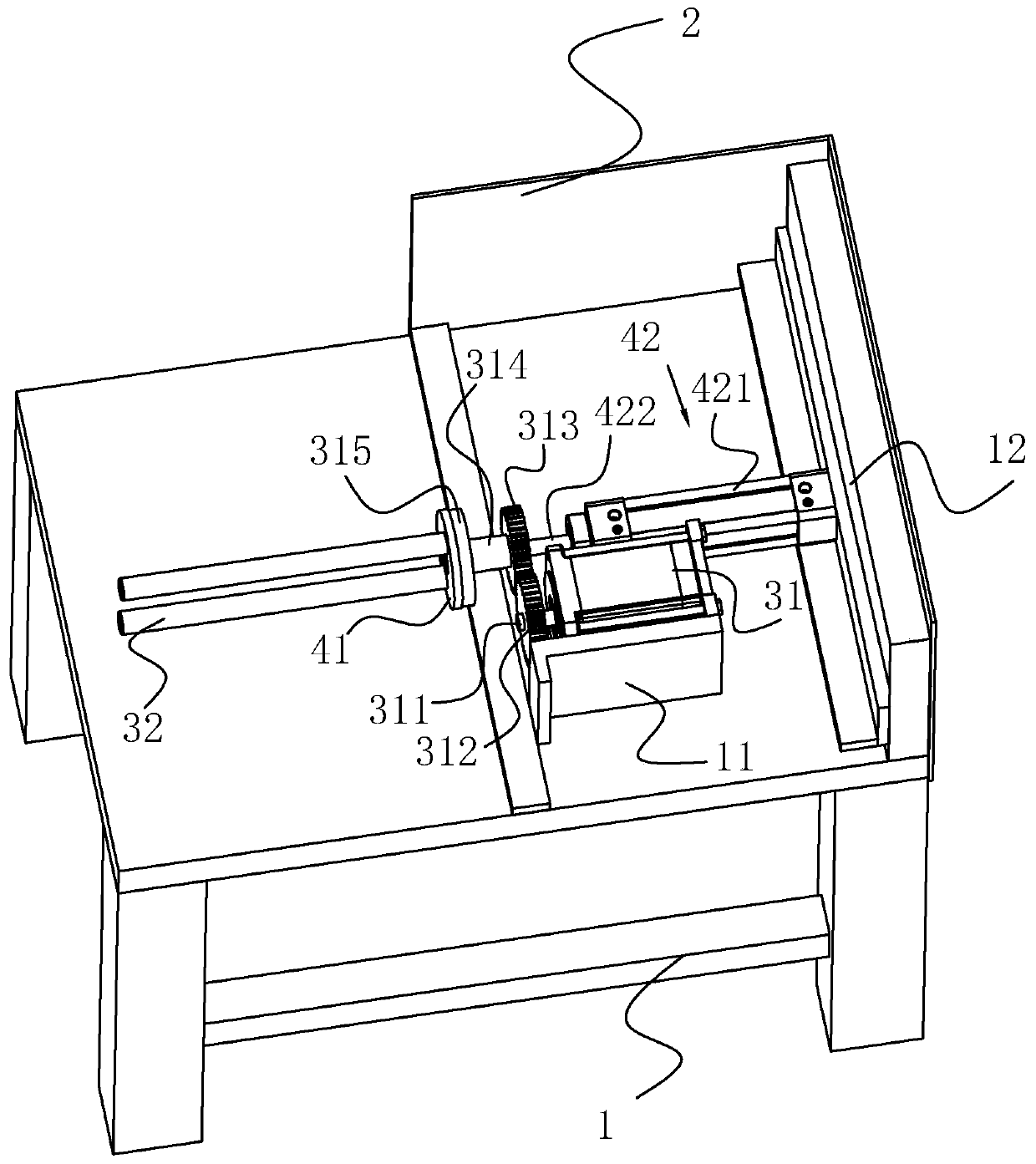

[0037] see image 3 and Figure 4 The curling device 3 includes a motor 31 located in the cover body 2 and two cloth rolls 32 extending out of the rectangular hole 21 for curling the carpet. The motor 31 is fixed on the frame body 1 by the fixing plate 11, and the motor 31 is provided with a rotating shaft. 311, the rotating shaft 311 is provided with a driving gear 312, the driving gear 312 is meshed with a driven gear 313, and the center of the side of the driven gear 313 close to the cloth rolling roller 32 is fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com