An emulsifier for the emulsification of alkenyl succinic anhydride

A technology of alkenyl succinic anhydride and emulsifier, which is applied in the direction of water repellent addition, etc., can solve the problems of insufficient compactness of the structure and the decline of sizing effect, and achieve the effects of improved stability, enhanced storage stability, and obvious anti-hydrolysis effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

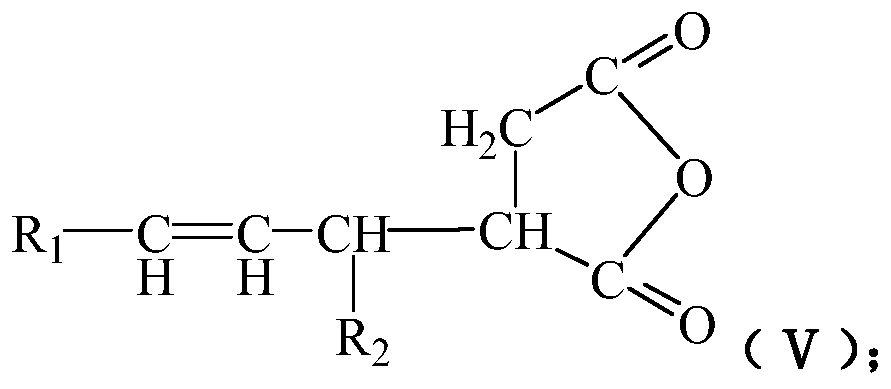

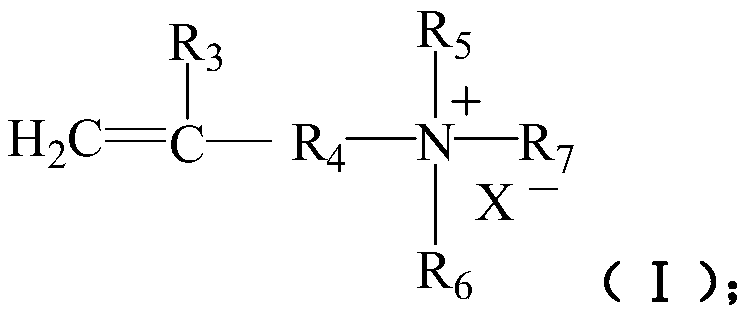

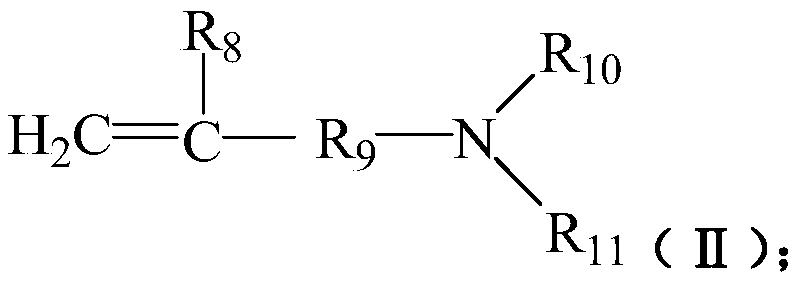

Method used

Image

Examples

Embodiment 1

[0099] Add 220 parts of deionized water, 40 parts of acrylamide, 3 parts of cetyl dimethyl allyl ammonium chloride (65%) , 20 parts of methacryloyloxyethyltrimethylammonium chloride (80%), 0.015 part of ethylenediaminetetraacetic acid disodium salt, 0.1 part of sodium hypophosphite, stir to make it fully dissolve, and adjust the pH to the level required by the trigger system. pH is required, adjust the speed to 300 rpm, pass nitrogen for 30 minutes to remove oxygen, adjust the system temperature to the initiation temperature, add 2 parts of 1% ammonium persulfate aqueous solution to initiate the reaction, and add 1 part of 1 more after 1-4 hours % V50 aqueous solution and continue to react for 1-3 hours, lower the temperature to 30-45°C, add glyoxal aqueous solution dropwise, and at the same time adjust the pH to 6.0-10.0 with aqueous sodium hydroxide solution, after reaching the viscosity, add dilute sulfuric acid to terminate the reaction, Then add sodium pyrosulfite solutio...

Embodiment 2

[0101] Add 225 parts of deionized water, 32 parts of acrylamide, 0.02 parts of N, N-methylenebisacrylamide, 3 parts of octadecyl Dimethyl allyl ammonium chloride (65%), 32 parts of dimethyl diallyl ammonium chloride (60%), 0.015 part of diethylene triamine pentaacetic acid sodium salt, 0.5 part of isopropanol, stir to make It is fully dissolved, adjust the pH to the required pH of the initiation system, adjust the rotation speed to 300 rpm, pass nitrogen gas for 30 minutes to remove oxygen, adjust the temperature of the system to the initiation temperature, and then add 2 parts of 1% ammonium persulfate aqueous solution to initiate the reaction. After 1-4 hours, add 1 part of 1% V50 aqueous solution again and continue to react for 1-3 hours, cool down to 30-45°C, add glutaraldehyde aqueous solution dropwise, and at the same time adjust pH to 6.0-10.0 with sodium carbonate aqueous solution to reach viscosity Finally, add dilute hydrochloric acid to terminate the reaction, then ...

Embodiment 3

[0103] Add 225 parts of deionized water, 32 parts of acrylamide, 0.02 parts of N, N-methylenebisacrylamide, 3 parts of octadecyl Dimethyl allyl ammonium chloride (65%), 32 parts of dimethyl diallyl ammonium chloride (60%), 0.015 part of EDTA disodium salt, 0.5 part of isopropanol, stir to make It is fully dissolved, adjust the pH to the required pH of the initiation system, adjust the rotation speed to 300 rpm, pass nitrogen gas for 30 minutes to remove oxygen, adjust the temperature of the system to the initiation temperature, and then add 2 parts of 1% ammonium persulfate aqueous solution to initiate the reaction. After 1-4 hours, add 1 part of 1% V50 aqueous solution again and continue to react for 1-3 hours, cool down to 30-45°C, add succinic dialdehyde aqueous solution dropwise, and at the same time adjust the pH to 6.0-10.0 with potassium hydroxide aqueous solution to reach After the viscosity is reached, add dilute sulfuric acid to stop the reaction, then add sodium bis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com