Computer room installation reverse construction method

A technology of reverse construction and machine room, which is applied in the field of mechanical and electrical installation and construction in construction engineering, which can solve the problems of increasing construction difficulty, unfavorable machine room construction, and difficult turnover of pipelines, so as to reduce the dependence on preconditions, shorten the period of mechanical and electrical installation, and open up the construction space Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The patent of the present invention is further described in conjunction with the accompanying drawings.

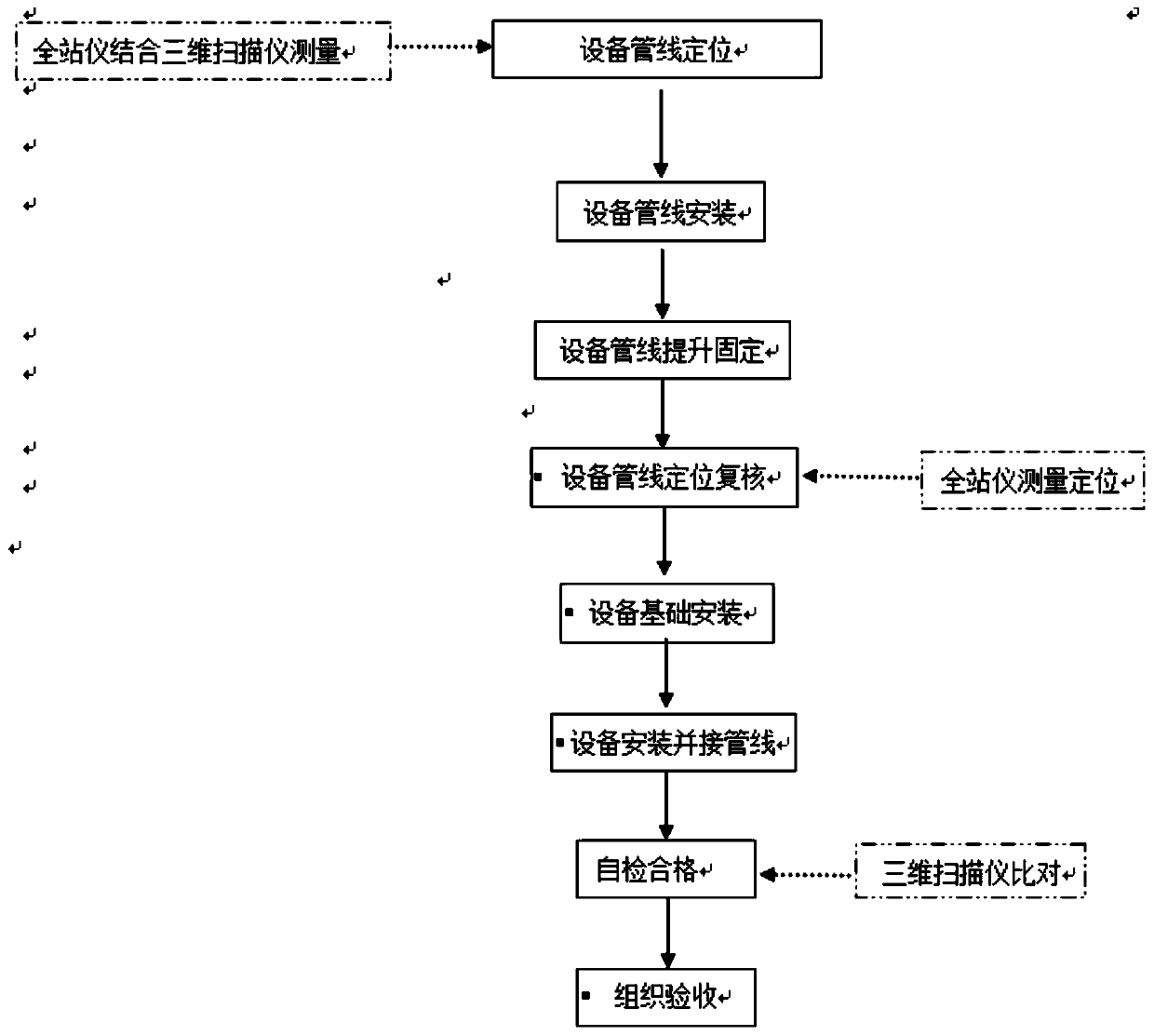

[0013] Such as figure 1 As shown, the machine room installation reverse construction method of the present invention, the machine room at least includes the equipment foundation, equipment, and equipment pipelines, and is characterized in that it includes the following steps: Step 1. Use a total station in combination with a three-dimensional scanner to carry out all the equipment pipelines in the machine room Positioning; step 2, complete the installation of all equipment pipelines in the machine room according to the positioning requirements of equipment pipelines; step 3, lift all equipment pipelines in the machine room and fix them with brackets; step 4, project the centerlines of all equipment pipelines in the machine room to the ground, and use the whole station The instrument will recheck the location of all equipment pipelines in the computer room; Step 5, c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com